Automatic bending mechanism for connector contact pin

A bending mechanism and connector technology, applied in the direction of contact manufacturing, etc., can solve the problems of inability to guarantee the same size, low degree of automation, low work efficiency, etc., to prevent pin breakage, facilitate bending work, and improve efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiments are described below with reference to the drawings. In addition, the examples shown below do not limit the content of the invention described in the claims in any way. In addition, all the contents of the configurations shown in the following embodiments are not limited to be essential to the solution of the invention described in the claims.

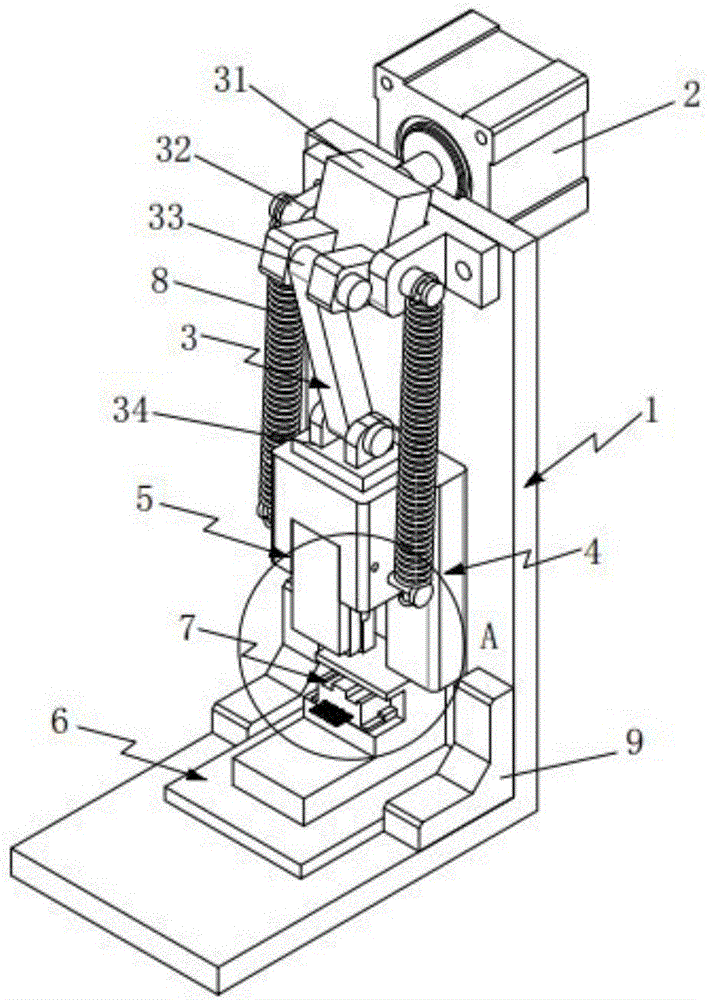

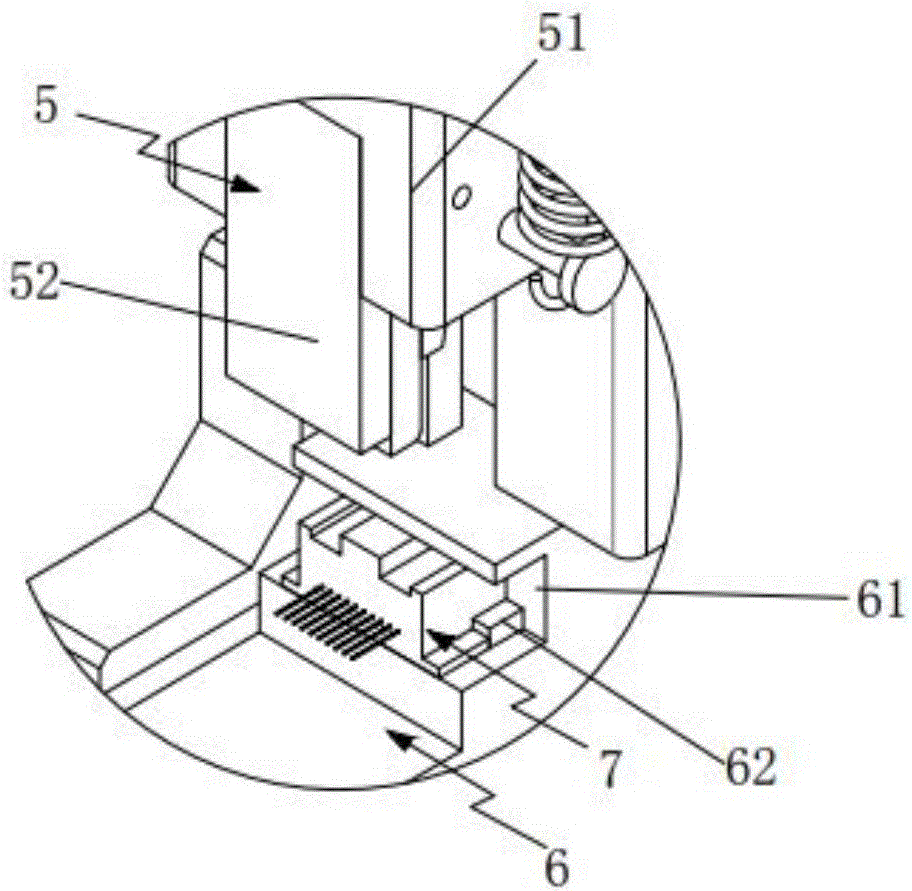

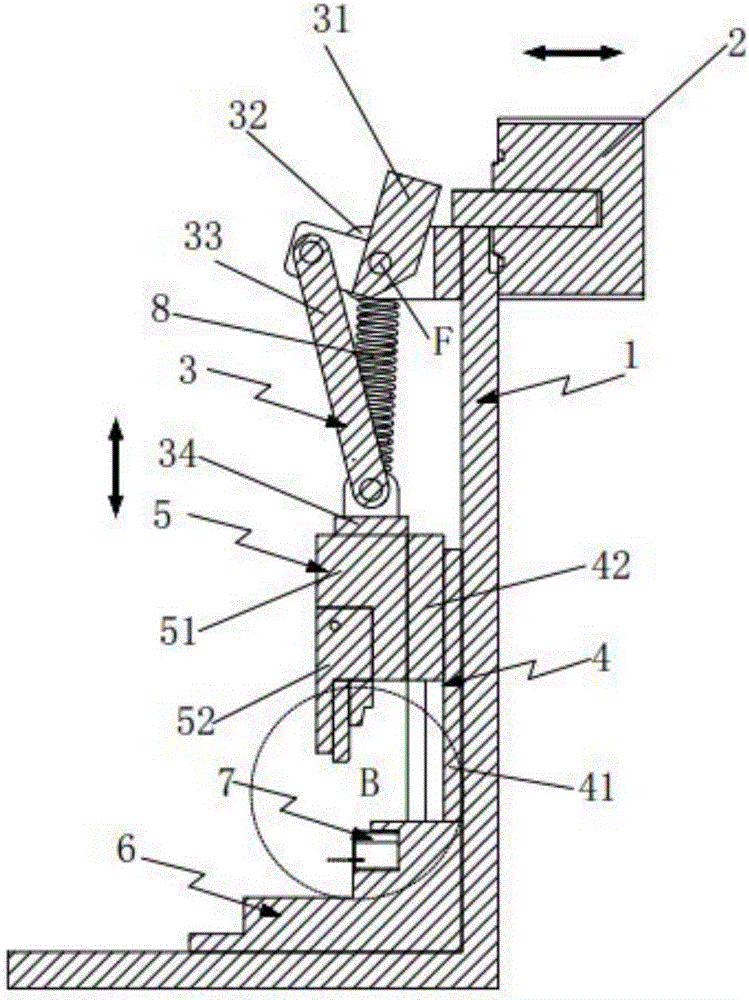

[0033] Such as figure 1 As shown, the present invention provides a pin header connector installation device, including a downward pressure cylinder 2 and a link mechanism 3 arranged in the vertical direction of the frame 1, and a connector fixing seat 6 arranged horizontally on the frame 1 The connecting rod mechanism 3 is connected to the bending mechanism 5; the connector holder 6 is fixed with a connector 7; the pressing cylinder 2 pushes the connecting rod mechanism 3, and the connecting rod mechanism 3 drives the bending mechanism 5 to perform Pressing action, the connector 7 is pressed down to complete the ben...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com