Metal building material bending equipment

A technology of building materials and equipment, which is applied in the field of bending equipment for metal building materials, can solve the problems of inconvenient cutting and achieve the effect of easy cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

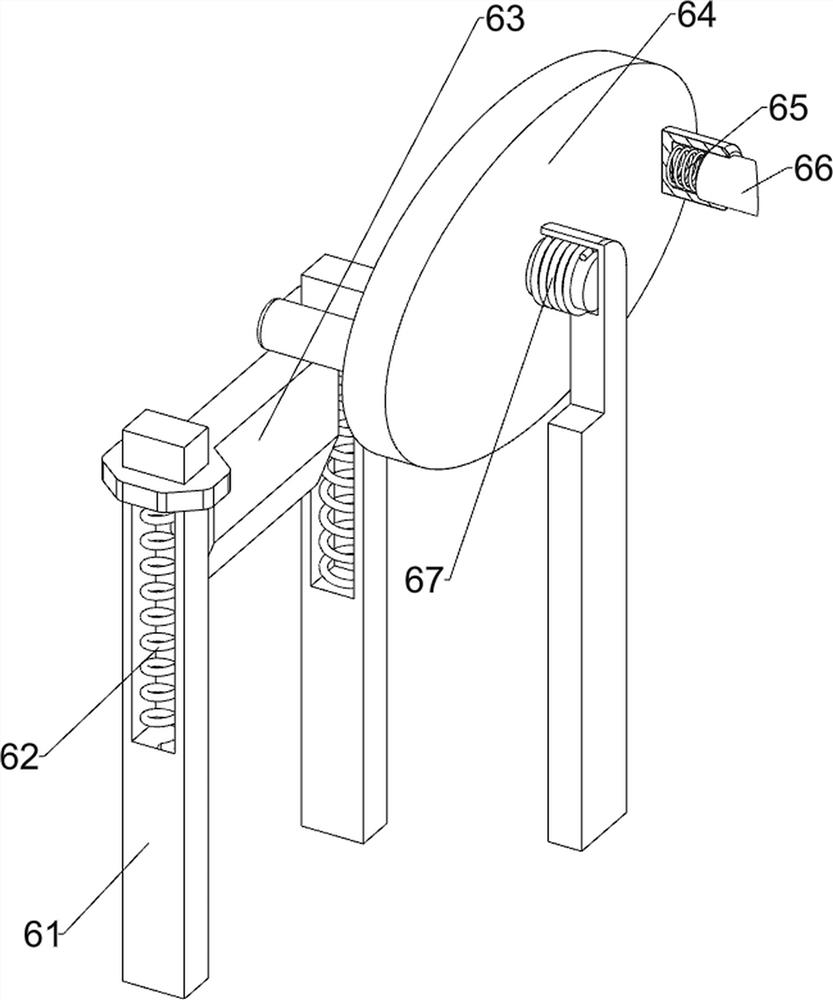

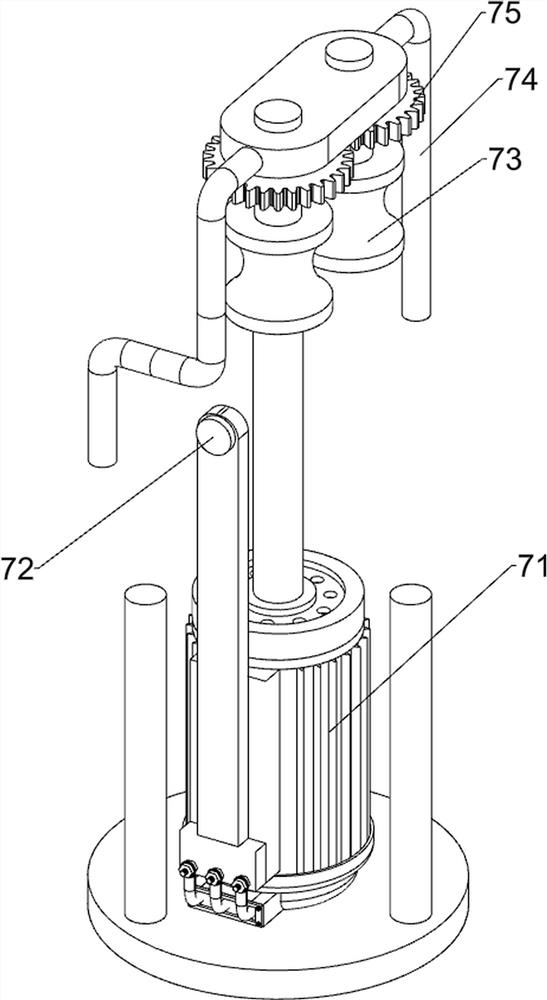

[0029] A metal building material bending equipment, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a support frame 1, a cylinder 3, a bending block 4, a first rotating wheel 5, a bending mechanism 2, a cutting mechanism 6 and a feeding mechanism 7, and a bending mechanism 2 is arranged in the middle of the top of the support frame 1 to support A cylinder 3 is provided in the middle of the rear side of the frame 1, and a bending block 4 is provided on the front side of the piston rod of the cylinder 3. The bending block 4 is slidingly matched with the support frame 1, and two first rotating wheels are arranged symmetrically on the left and right sides of the support frame 1. 5. The upper right side of the support frame 1 is provided with a cutting mechanism 6, and the upper right side of the support frame 1 is provided with a feeding mechanism 7.

[0030] The bending mechanism 2 includes a first wedge block 21, a placement plate 22, a first chute...

Embodiment 2

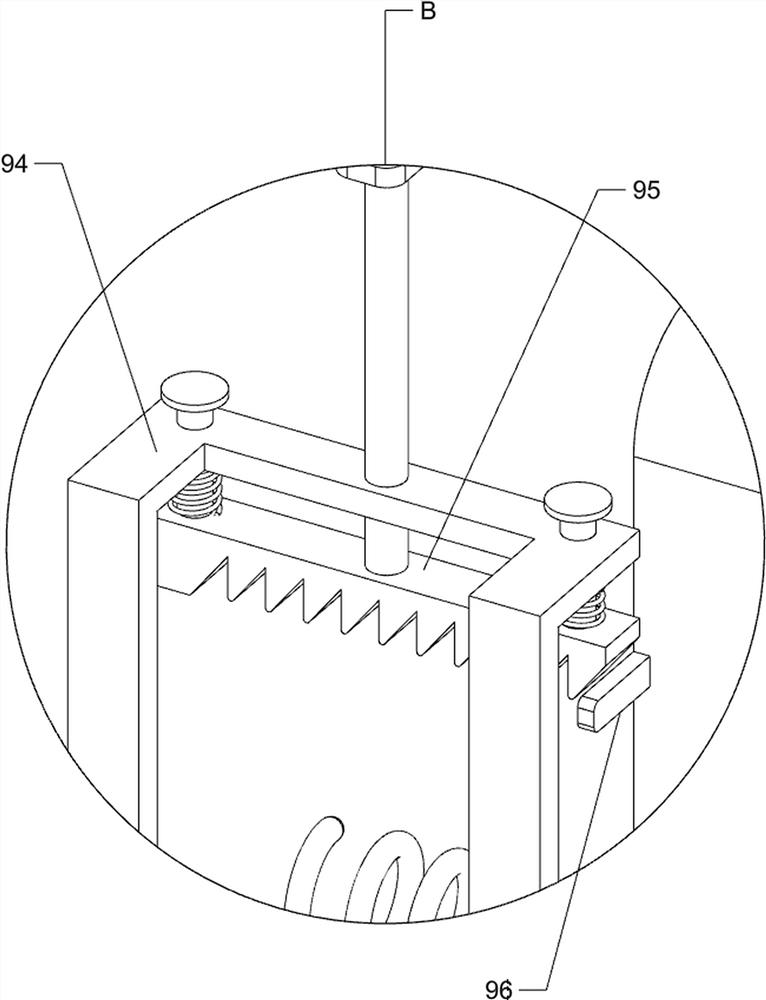

[0035] On the basis of Example 1, such as Figure 5 , Figure 6 , Figure 7 , Figure 8 and Figure 9 As shown, it also includes a material taking assembly 8, and the material taking assembly 8 includes a third chute 81, a fourth spring 82, a third wedge block 83, a clamping block 84, a second torsion spring 85 and a rotating shaft 86, and the support frame 1 There are three third chute 81 on the top, and a third wedge-shaped block 83 is slid between the third chute 81, and a fourth spring 82 is respectively arranged between the third wedge-shaped block 83 and the third chute 81. Three wedge-shaped blocks 83 cooperate with the sliding type of first rotating wheel 5, and the left and right sides of the 3rd wedge-shaped block 83 front sides are all rotationally symmetrically provided with rotating shaft 86, and all rotationally on rotating shaft 86 are provided with clamping block 84, and clamping block 84 A second torsion spring 85 is provided between the third wedge block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com