Bending machine

A bending machine and combined technology, applied in the field of bending machines, can solve the problems of poor bending effect, high cost, and low efficiency, and achieve the effects of low manufacturing cost, simple structure, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

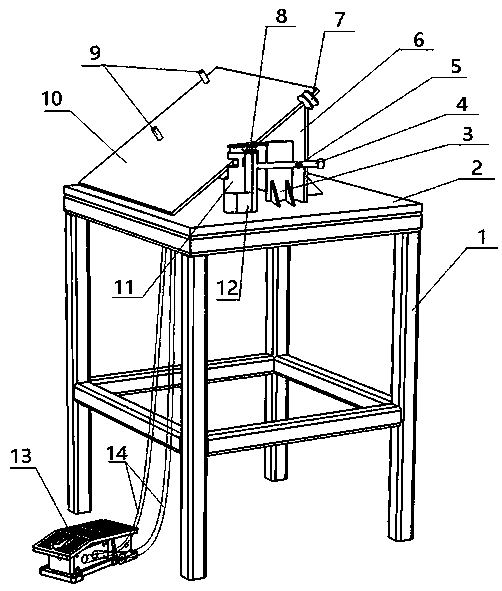

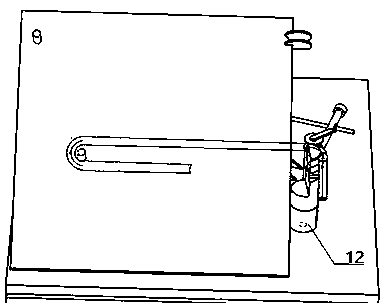

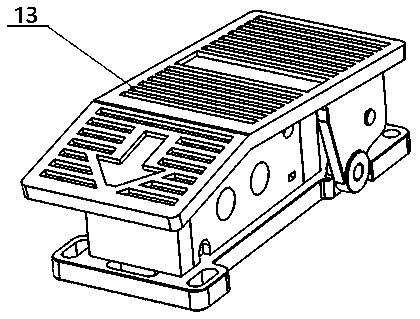

[0027] Embodiment 1: as Figure 1-10 As shown, a bending machine includes a frame 1, an upper panel 2, a cylinder support plate 3, a handle 4, a cylinder 5, a vertical plate 6, a bending wheel 7, a pin 8, a positioning pin 9, a bottom plate 10, and a Wheel 11, turning block 12, foot switch 13, air pipe 14, deformation wheel 15;

[0028] Described frame 1 is welded together with upper panel 2, and cylinder support plate 3 and vertical plate 6 are vertically welded on upper panel 2 respectively, to support cylinder 5 and base plate 10, and base plate 10 forms certain angle with upper panel 2, and one end It is welded with the upper panel 2, and the other end is welded with the vertical plate 6. The roller 11 and the rotary block 12 are connected with the upper panel 2 through screws, and the roller 11 is stepped, and the upper half is 2 / of the shaft diameter. 3 and has an arc-shaped groove, wherein the roller 11 is fixed relative to the upper panel 2, and the two bosses of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com