Water tank bending method and device for stainless steel cabinet production

A bending device, stainless steel technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of low automation, low work efficiency and high processing cost, and achieve low work cost, high work efficiency, and improved yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in more detail below with reference to the embodiments and the drawings, but the embodiments of the present invention are not limited thereto.

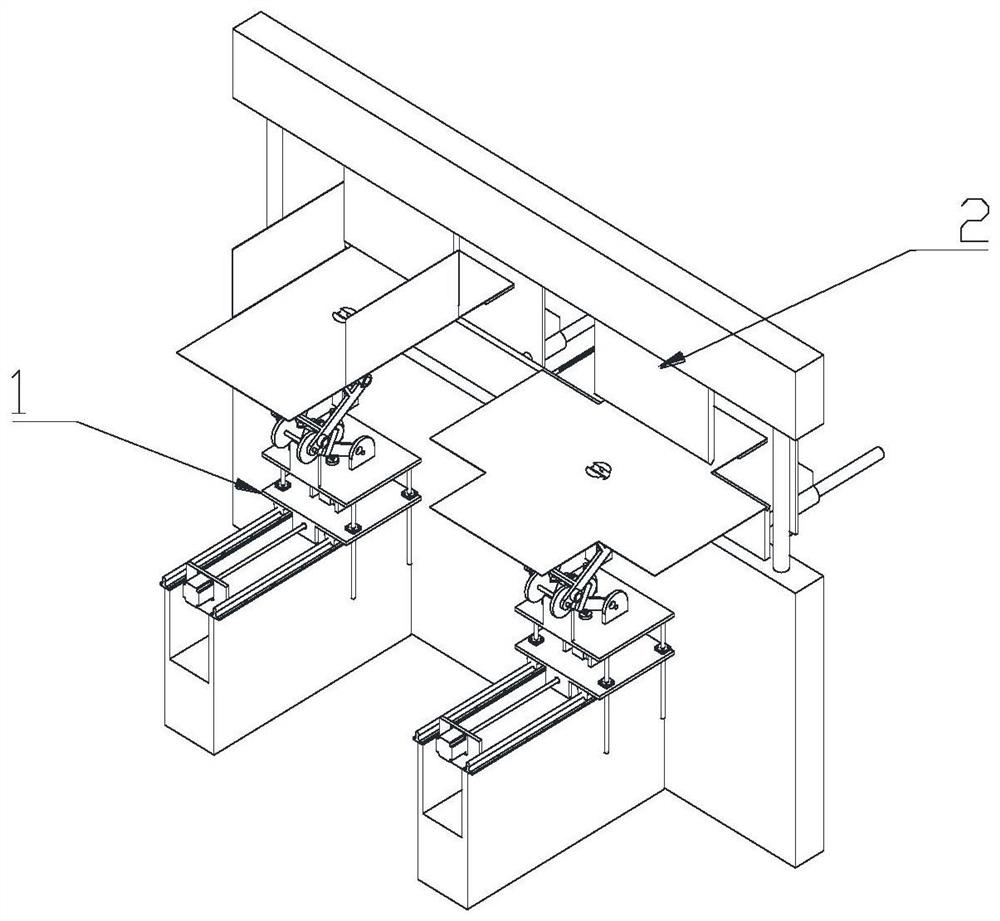

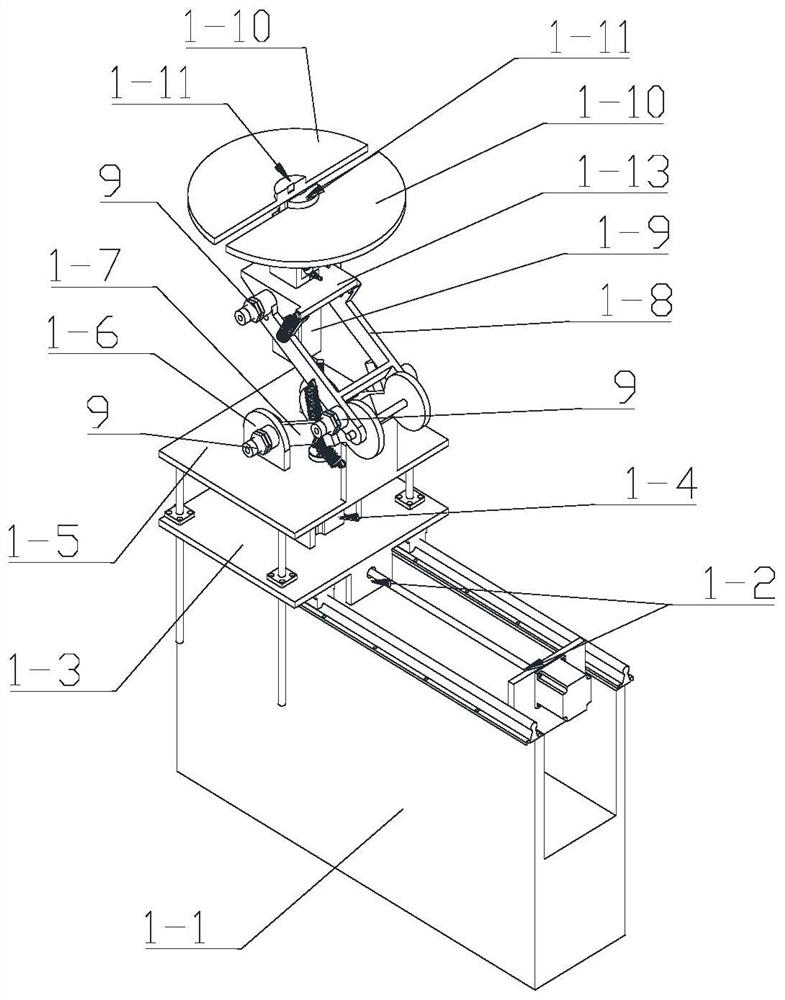

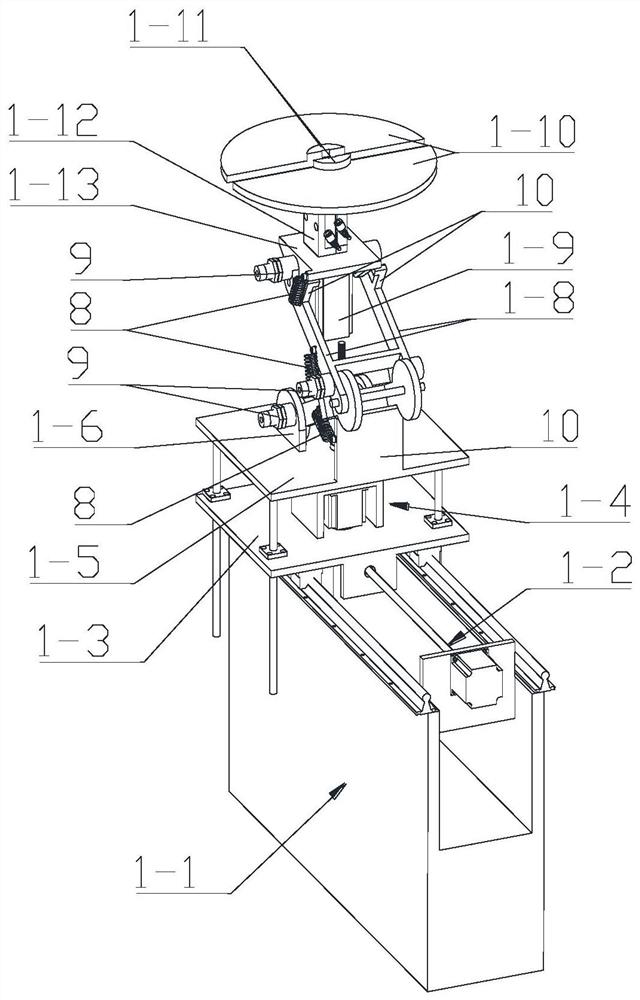

[0033] See Figure 1 - Figure 7 , The water tank bending apparatus for stainless steel cabinets produced by the present invention includes a mounting apparatus 1 and a bending device 2.

[0034] See Figure 1 - Figure 7 The installation device 1 includes a machine table 1-1, which is disposed on a mounting manipulator for loading a stainless steel plate member, and a manipulator for driving the loading mechanism. The movement drive mechanism 1-2 of the working station of the folding device 2, wherein the clamp robot includes a table 1-5, a mounting mechanism disposed on a table 1-5 for driving the assembly mechanism. Rotating rotary drive mechanisms 1-9, a supporting mechanism for driving the vertical movement of the assembly mechanism and a support mechanism for supporting the adaptive swing d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com