Battery tab bending mechanism

A technology of bending mechanism and battery tabs, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of manual battery removal speed limit, unstable manual operation, increased labor cost and management cost, etc. Achieve the effect of reducing defect rate, reducing production cost, improving work efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

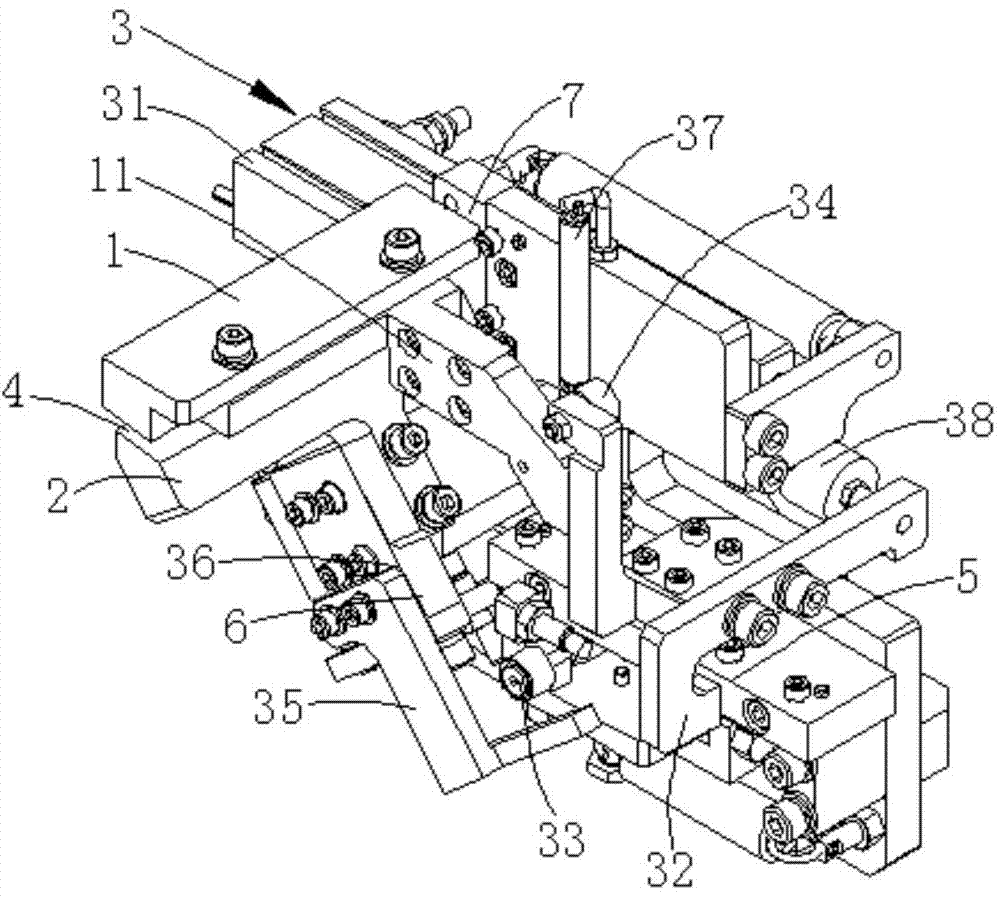

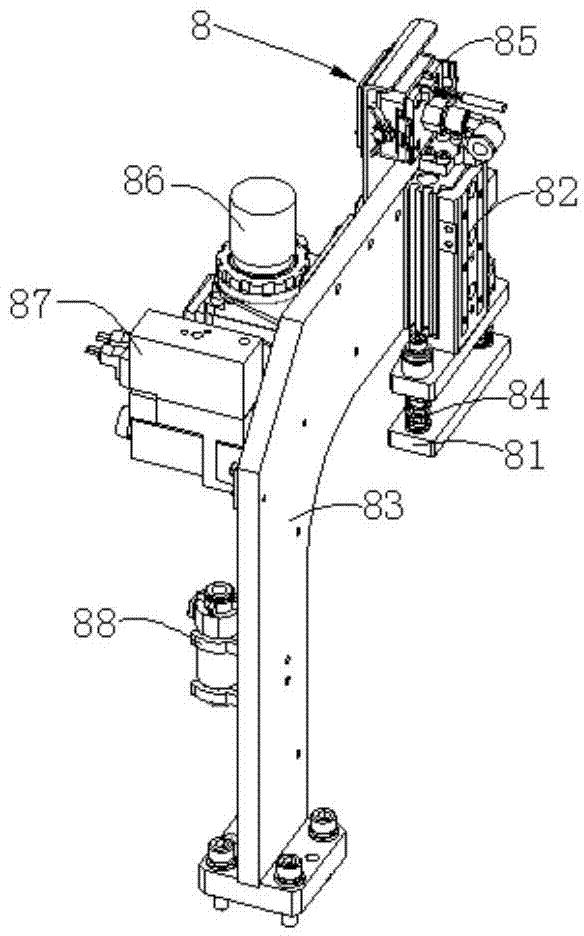

[0026] A battery tab bending mechanism disclosed in the present invention is used for automatically bending the battery tab. like figure 1 As shown, the battery lug bending mechanism of Embodiment 1 of the present invention includes an upper bending head 1, a lower bending head 2, and a bending head driving mechanism 3, and the upper bending head 1 and the lower bending head 2 are arranged opposite to each other up and down. And a bending gap 4 is formed between the two, and the battery tab is located in the bending gap 4 during bending. The lower bending head 2 rises to be flush with the upper surface of the battery cell under the drive of the bending head driving mechanism 3, and the upper bending head 1 is pressed down to meet the lower bending head 2 under the driving of the bend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com