Bending mechanism of battery cutting shaper

A bending mechanism and shaping machine technology, applied in non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve problems such as low efficiency, unguaranteed safety, inconsistent battery thickness, etc. Process time and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings of the present invention.

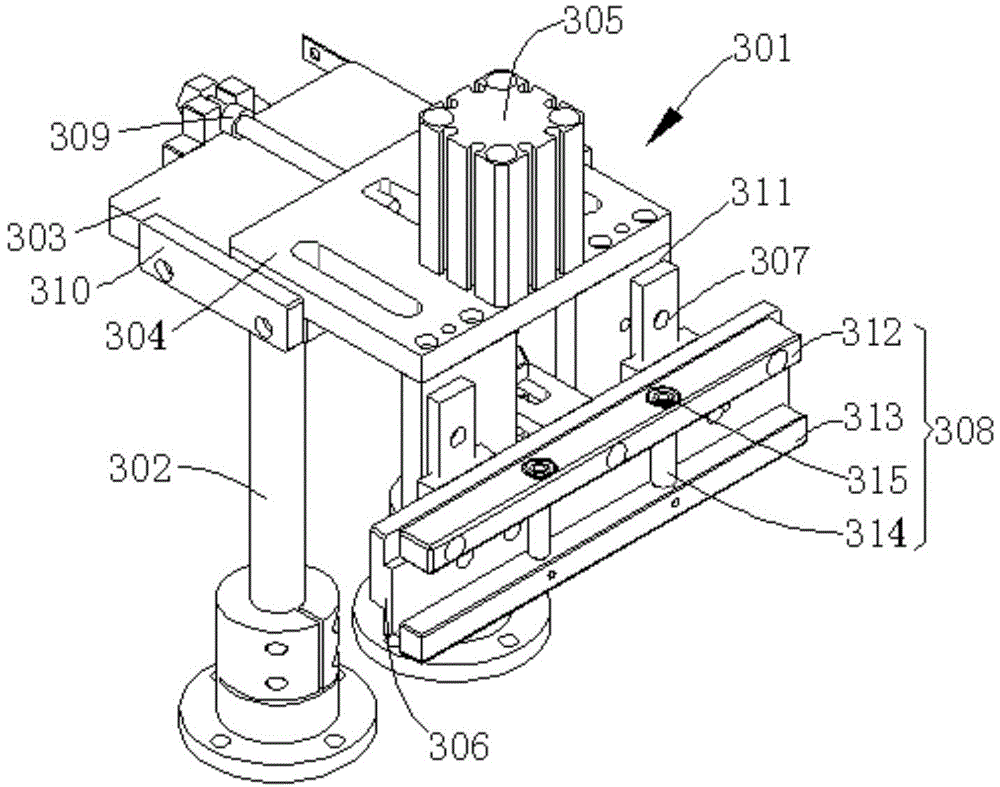

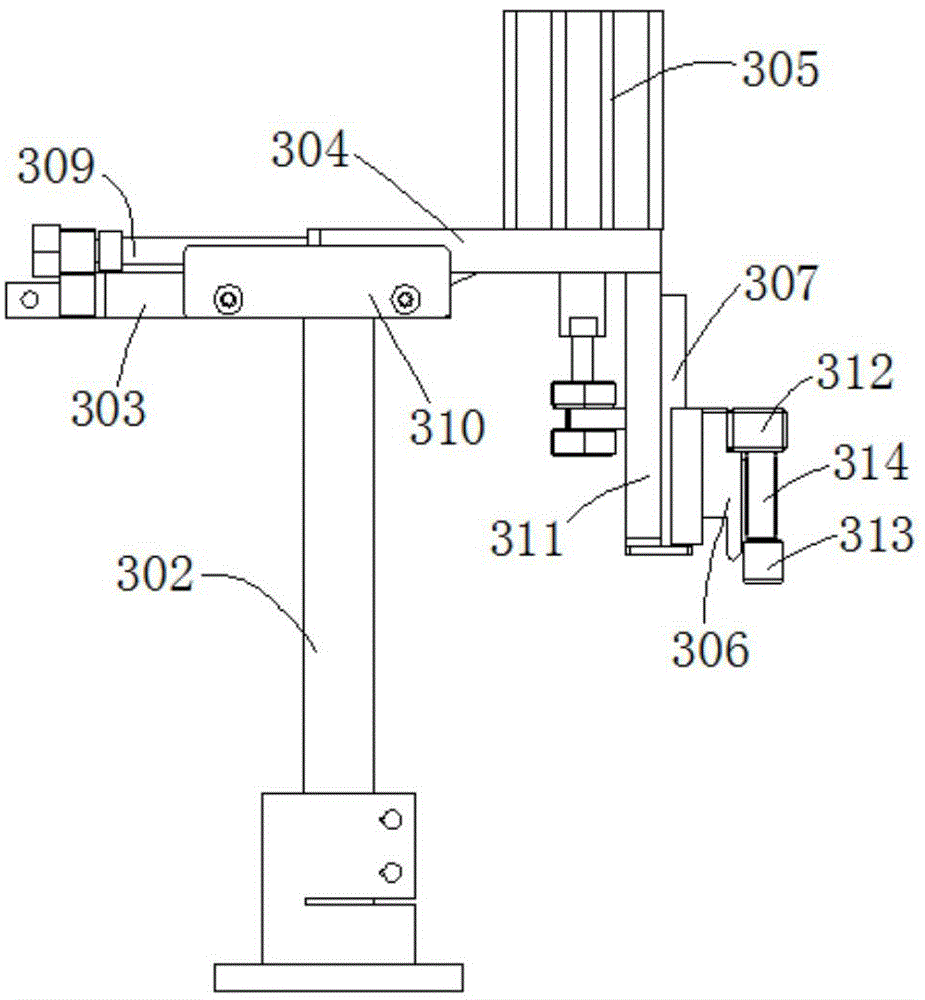

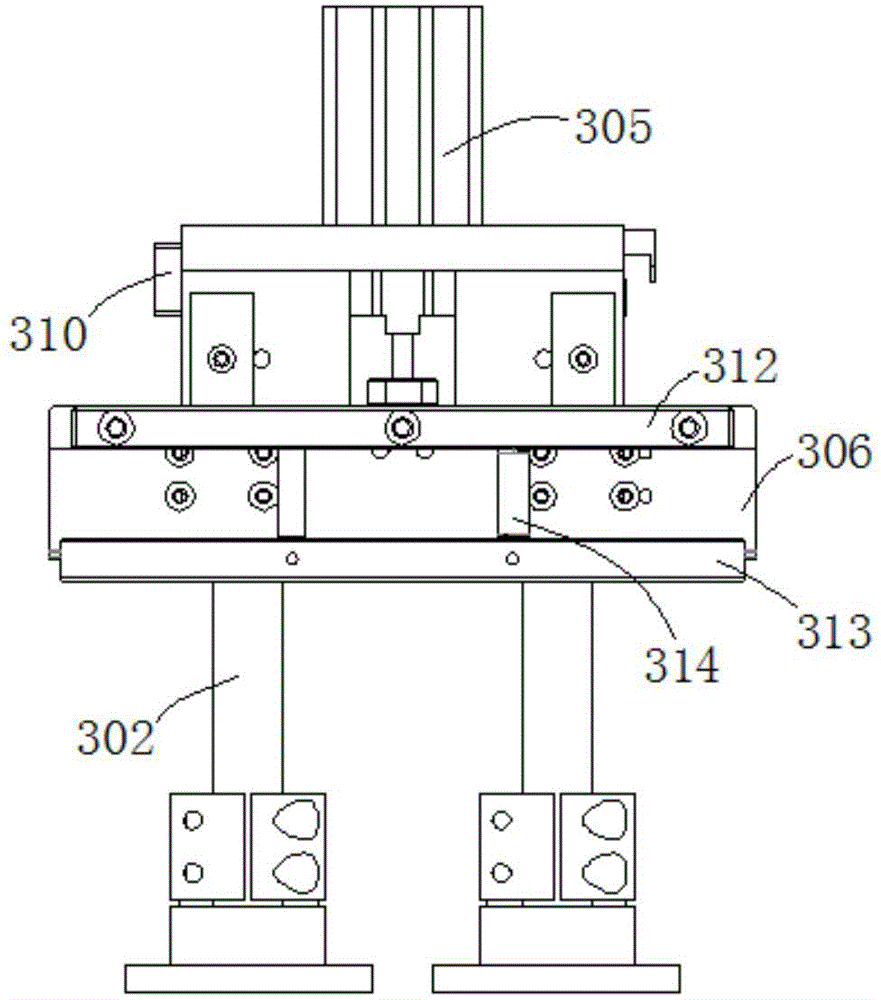

[0023] The invention discloses a bending mechanism of a battery cutting and shaping machine, which is used for automatically bending the battery side during the battery cutting and shaping process. The bending mechanism of the battery cutting and shaping machine of the present invention includes a first bending mechanism 301 and a second bending mechanism 301 arranged oppositely. When the battery is located between the first and second bending mechanisms 301, the first and second bending The mechanism 301 bends the left and right sides of the battery synchronously.

[0024] combine Figure 1 ~ Figure 3 As shown, the first and second bending mechanisms 301 of the present invention include a bracket 302, a fixed pallet 303, an adjustment plate 304, a driver 305, a bending tool 306, a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com