Cold-rolled hot-galvanized complex phase steel and preparation method thereof

A technology of multi-phase steel and hot-dip galvanizing, which is applied in the field of cold-rolled hot-dip galvanized multi-phase steel, which can solve problems such as low bending performance and hole expansion performance, inability to meet flanging and bending forming parts, and low yield ratio.

Inactive Publication Date: 2018-09-04

SHOUGANG CORPORATION

View PDF6 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Traditional high-strength steel is mainly dual-phase steel, and its structure is mainly composed of soft ferrite matrix and high-strength martensite. The performance characteristics of this structure are low yield ratio, high strength, etc. , suitable for the production of stamping forming parts; but due to the large hardness difference between ferrite and martensite soft and hard phases, its bending performance and hole expansion performance are low, which cannot meet the production of flanging bending forming parts

Method used

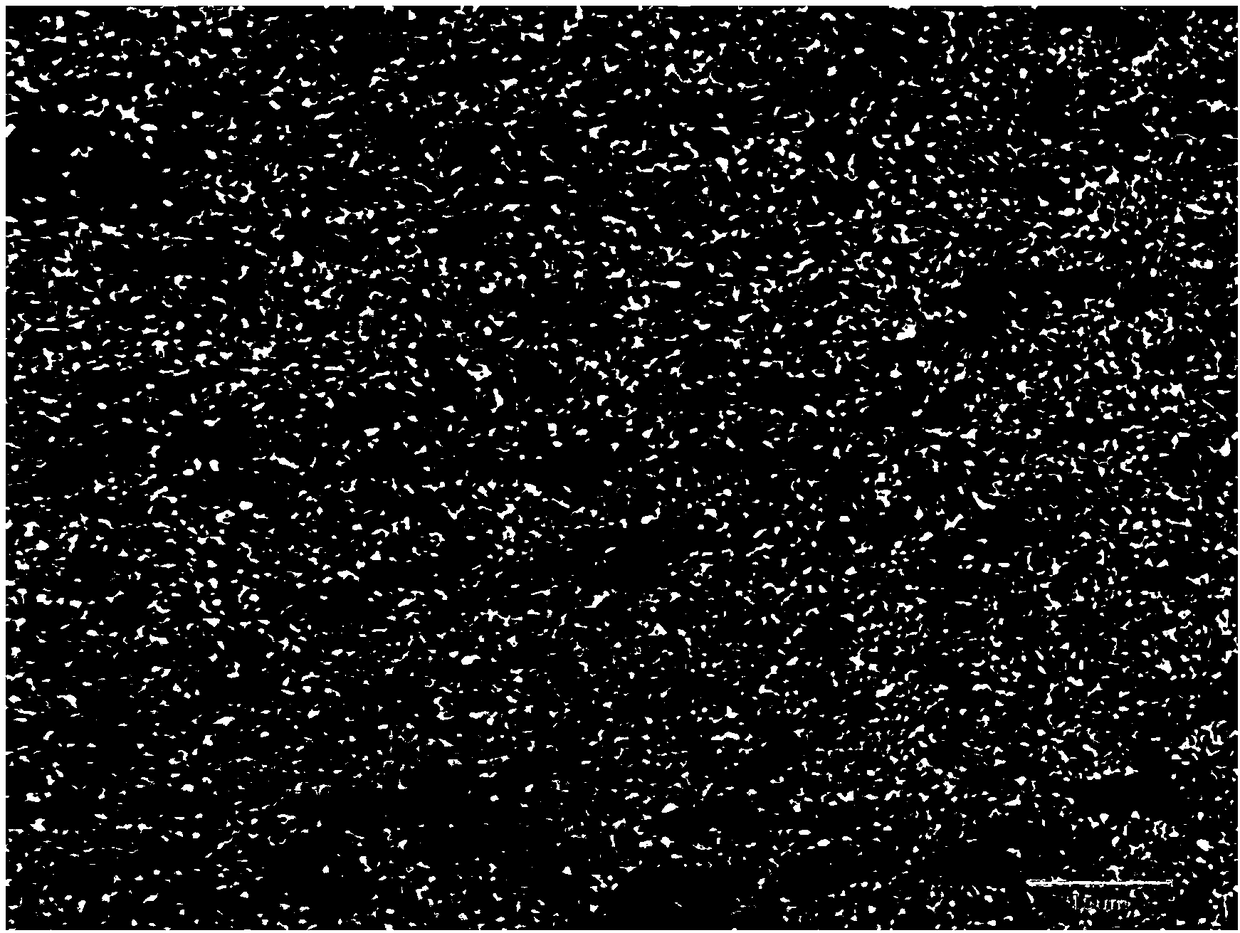

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0043] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Login to View More

Abstract

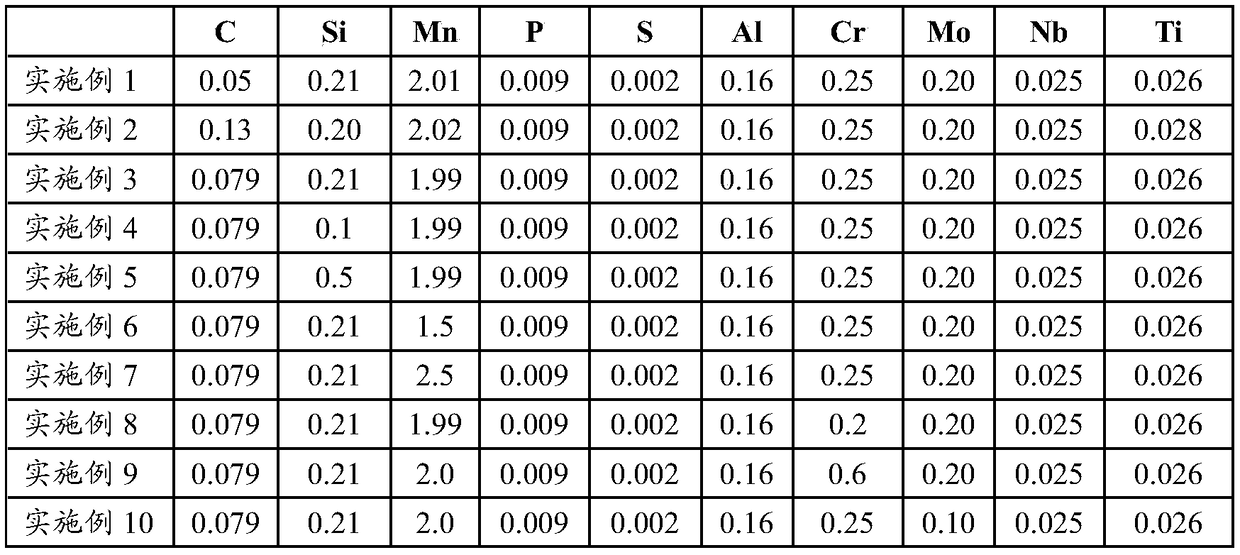

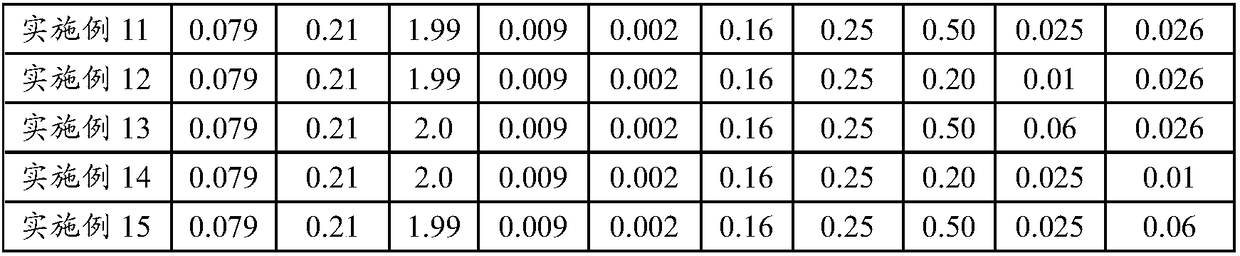

The invention relates to a kind of cold-rolled hot-galvanized complex phase steel. Chemical components of the cold-rolled hot-galvanized complex phase steel comprise, by weight, 0.05-0.13% of C, 0.1-0.5% of Si, 1.5-2.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.015% of S, 0.1-0.6% of Al, 0.2-0.6% of Cr, 0.1-0.5% of Mo, 0.01-0.06% of Nb, 0.01-0.06% of Ti, and the balance Feand inevitable impurities. The invention further relates to a preparation method of the cold-rolled hot-galvanized complex phase steel. The preparation method comprises the following steps of castingmolten steel into a steel billet; conducting hot rolling on the steel billet to obtain a hot-rolled plate and conducting cold rolling on the hot-rolled plate to obtain a cold-hardened steel strip; conducting continuous galvanizing and annealing process treatment on the cold-hardened steel strip to obtain a finished cold-rolled hot-galvanized complex phase steel product. The bending performance ofthe cold-rolled hot-galvanized complex phase steel is improved on the basis of meeting the requirement for strength.

Description

technical field [0001] The invention discloses a cold-rolled hot-dip galvanized multiphase steel and a preparation method thereof, belonging to the technical field of cold-rolled hot-dip galvanized multiphase steel. Background technique [0002] In recent years, with the development of the automobile industry and the needs of energy saving and emission reduction, the steel used in automobiles has gradually developed into high-strength steel, and at the same time, the number of formed parts such as bending and flanging used in high-strength steel is increasing. Traditional high-strength steel is mainly dual-phase steel, and its structure is mainly composed of soft ferrite matrix and high-strength martensite. The performance characteristics of this structure are low yield ratio, high strength, etc. , suitable for the production of stamping and forming parts; but due to the large difference in hardness between ferrite and martensite soft and hard phases, its bending performance...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/38C22C38/02C22C38/06C22C38/22C22C38/26C22C38/28

CPCC22C38/38C22C38/02C22C38/06C22C38/22C22C38/26C22C38/28

Inventor 谢春乾邝霜韩赟刘华赛邱木生姜英花齐秀美王勇围刘广会滕华湘崔阳李飞章军朱国森

Owner SHOUGANG CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com