Hook production line

A production line and hook technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of poor connection in the previous process, affecting the bending effect, and small size of short rods, etc., to achieve good top bending effect, Improve feeding efficiency and ensure heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

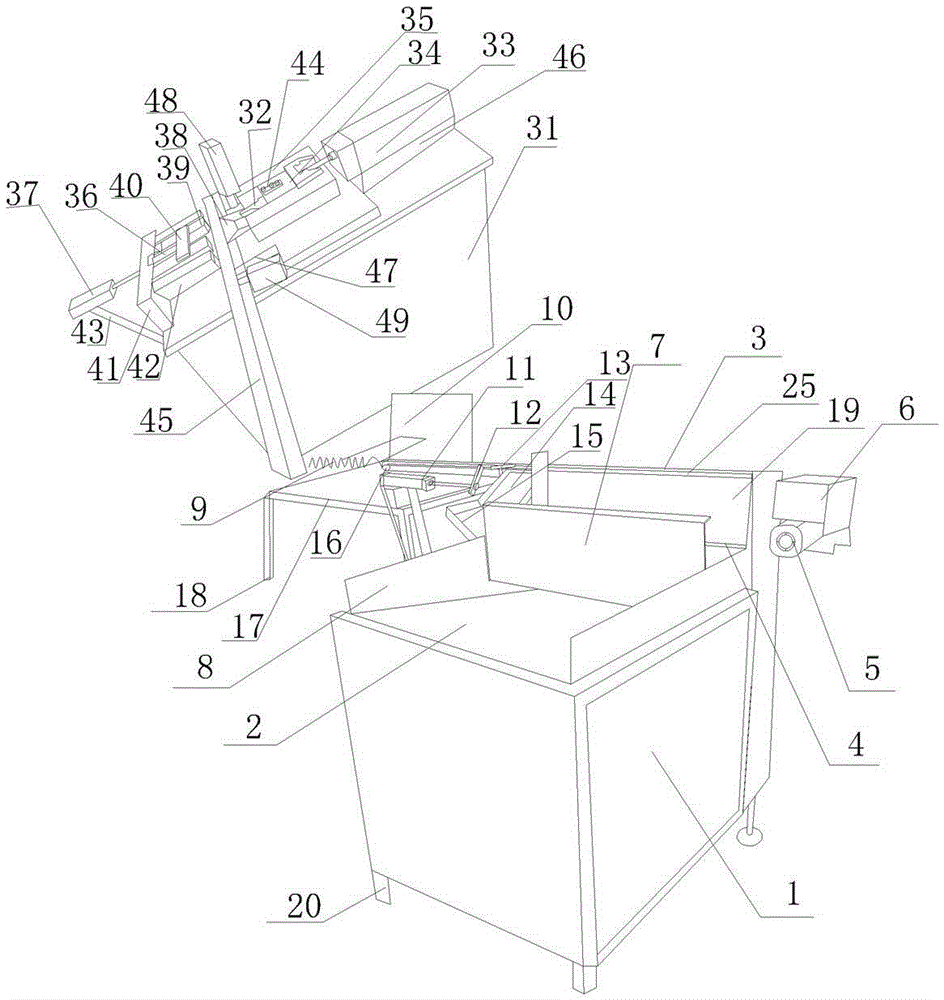

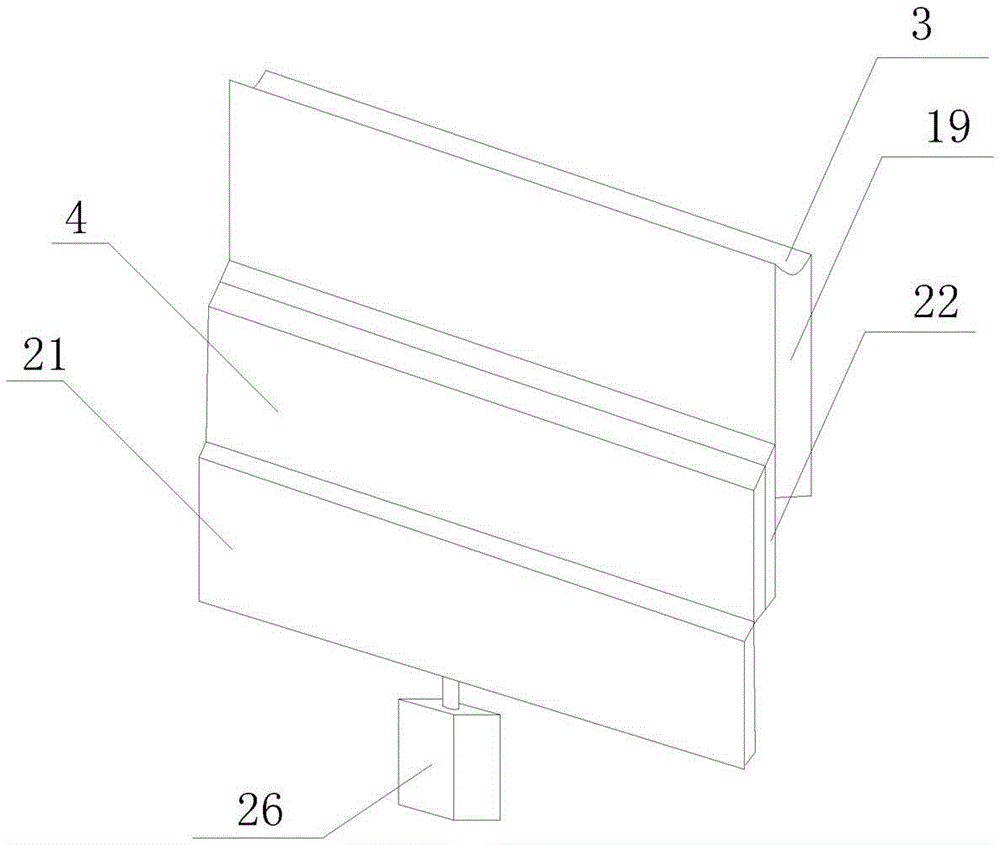

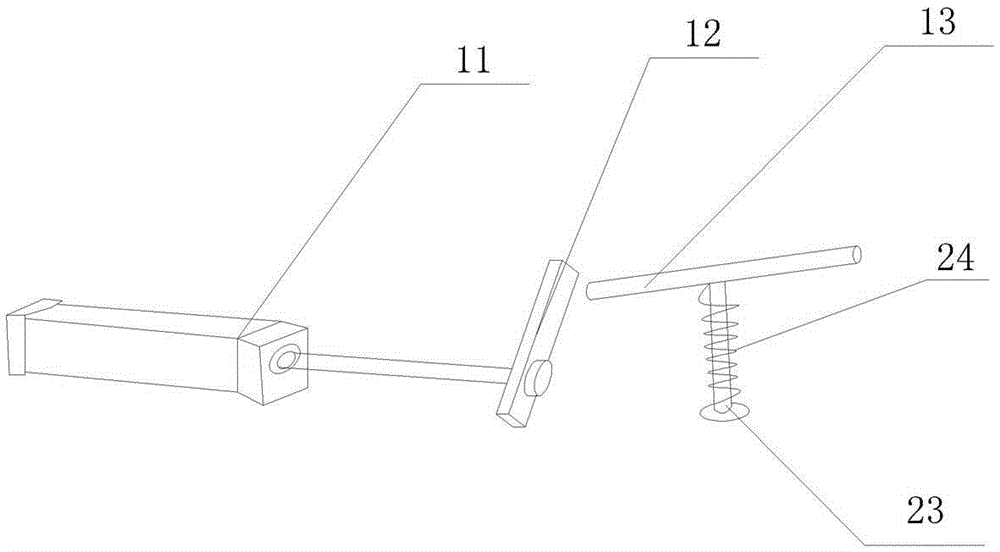

[0045] Such as Figure 1-5 As shown, a hook production line includes a short rod feeding and conveying heating device and a short rod bending device. The short rod feeding and conveying heating device includes a feeding mechanism, a conveying mechanism, a material breaking mechanism and a heating mechanism. The feeding mechanism includes The feeding bin 1, the feeding slope 2 and the supporting mechanism, the conveying mechanism includes the conveying sprocket 16, the conveying chain bracket 19, the conveying chain 3 and the conveying motor 5; the heating mechanism includes the electric heating tube 9 and the electric control box 10, the electric heating tube One end of 9 is connected with one end of the conveying chain 3. The supporting mechanism includes a supporting plate and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com