Large grain size asphalt macadam pavement flexible base layer material

A technology of asphalt crushed stone and flexible base, applied in the direction of roads, roads, and on-site coagulation pavement, etc., can solve the problem that semi-rigid base materials are prone to dry shrinkage and thermal cracks, reduce the performance of pavement, and reduce service life. and other problems to achieve the effect of ensuring road performance and mechanical performance, protecting the environment and reducing project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] A large-diameter asphalt macadam pavement flexible base material. The large-diameter asphalt macadam is added with an admixture, wherein the weight percentage of the large-diameter asphalt is 3-3.6%, and the admixture is rubber powder And steel slag powder, the weight percentage of the rubber powder is 0.85%, the weight percentage of the steel slag powder is 0.25%, and the balance is large-size crushed stone, wherein the size of the large-size asphalt and the large-size crushed stone Both are 25-70mm.

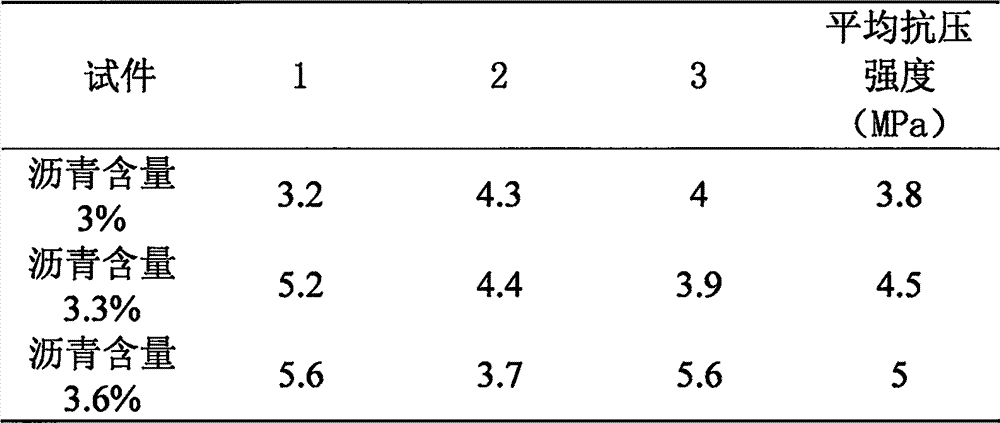

[0013] The compressive strength test of the flexible base material of the large-diameter asphalt macadam pavement of this embodiment is carried out, and the test results are shown in the following table.

[0014]

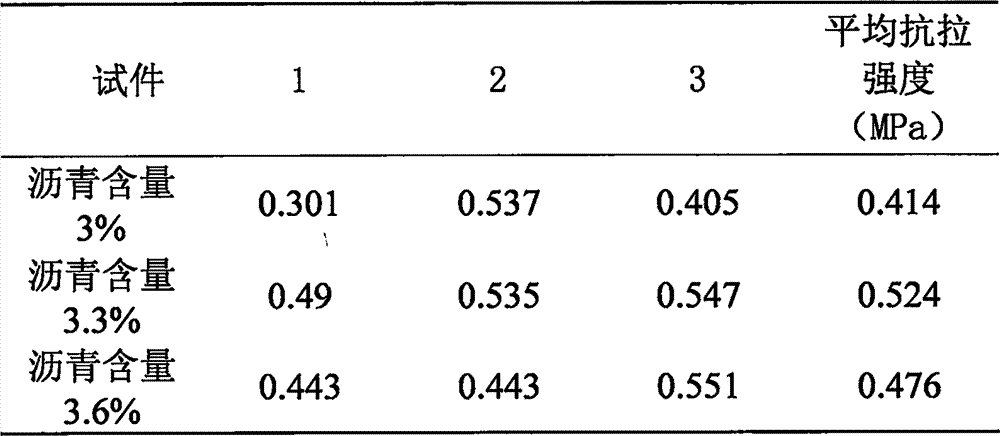

[0015] Then, the tensile strength test was performed on the flexible base material of the large-diameter asphalt macadam pavement of this embodiment, and the test results are shown in the following table.

[0016]

[0017] The rutting test was performed on the flexi...

Embodiment 2

[0023] The difference between this embodiment and the first embodiment is that the admixture is glass fiber and steel slag powder, the weight percentage of the glass fiber is 0.2%, and the weight percentage of the steel slag powder is 0.2%.

[0024] The compressive strength test was performed on the flexible base material of the large-diameter asphalt macadam pavement of this embodiment, and the test results are shown in the following table.

[0025]

[0026] Then, the tensile strength test was performed on the flexible base material of the large-diameter asphalt macadam pavement of this embodiment, and the test results are shown in the following table.

[0027]

[0028]

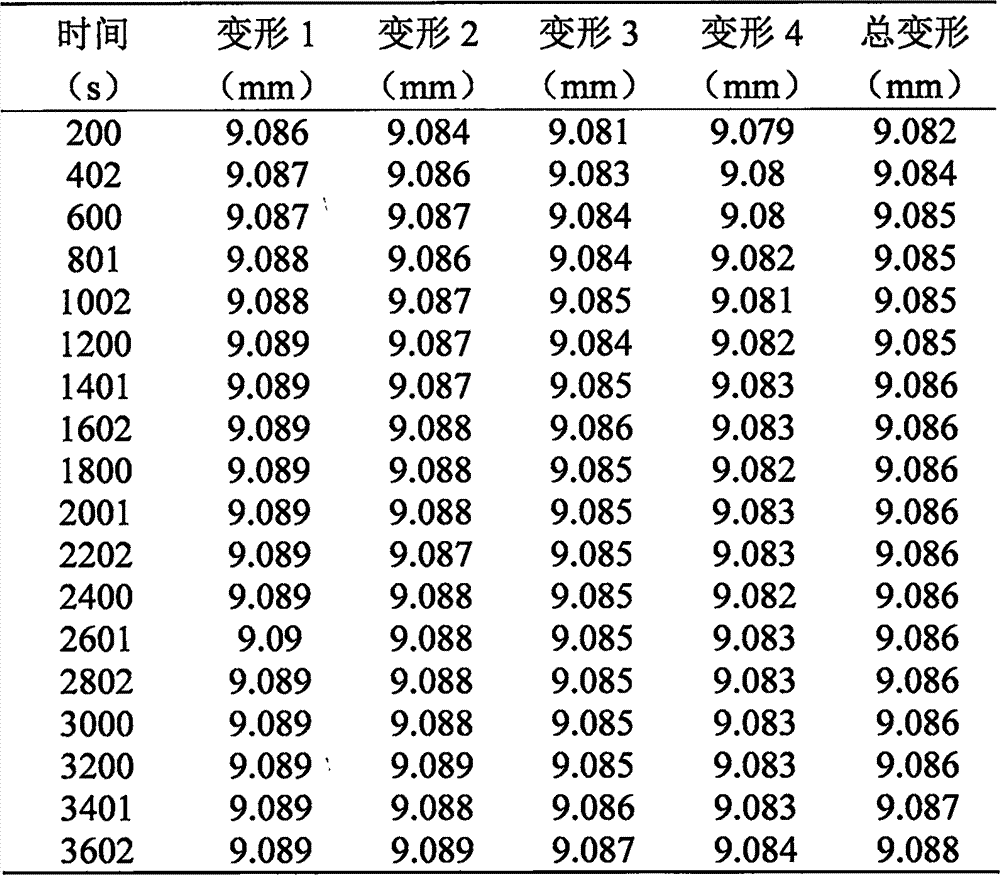

[0029] The rutting test was performed on the flexible base material of the large-diameter asphalt macadam pavement of this embodiment. When the asphalt content is 3%, the test results are as shown in the table below.

[0030]

[0031] When the asphalt content is 3.3%, the test results are as follows.

[0032]

[0033]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com