Asphalt pavement capable of providing charging function for vehicles in driving process

A technology for asphalt roads and vehicle driving, applied in circuit devices, vehicle components, battery circuit devices, etc., can solve the problems that restrict the development of electric vehicles, the limited capacity of on-board batteries, and the need to stop for charging, etc., and achieve good mechanical properties and good durability , the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] The weight ratio of natural basalt aggregate asphalt concrete in example 1 is: 10-16mm basalt 38%, 5-10mm basalt 36%, 3-5mm basalt 8%, less than 3mm basalt 8%, limestone mineral powder 10%, modified asphalt The oil-stone ratio is 6.4%, and the amount of polyester fiber is 0.3%.

example 2

[0034] The weight ratio of the steel slag aggregate asphalt concrete in Example 2 is: 10-16mm steel slag coarse aggregate 38%, 5-10mm steel slag coarse aggregate 36%, and the rest are the same as the natural basalt aggregate asphalt concrete. The electromagnetic induction power transfer efficiency and road performance indexes of asphalt concrete with the same design gradation but different aggregates are shown in Table 1.

[0035] It can be seen from Table 1 that although the road performance indicators such as Marshall stability, water stability and anti-rutting stability of steel slag asphalt concrete have been improved to a certain extent, because the steel slag aggregate contains as much as 18.2% iron, the electric energy of the asphalt concrete Conduction efficiency decreased by 9.2%.

[0036] Table 1 Relevant performance indicators of aggregate asphalt concrete with different iron contents

[0037] performance parameters Example 1 Example 2 Aggregate ...

example 3

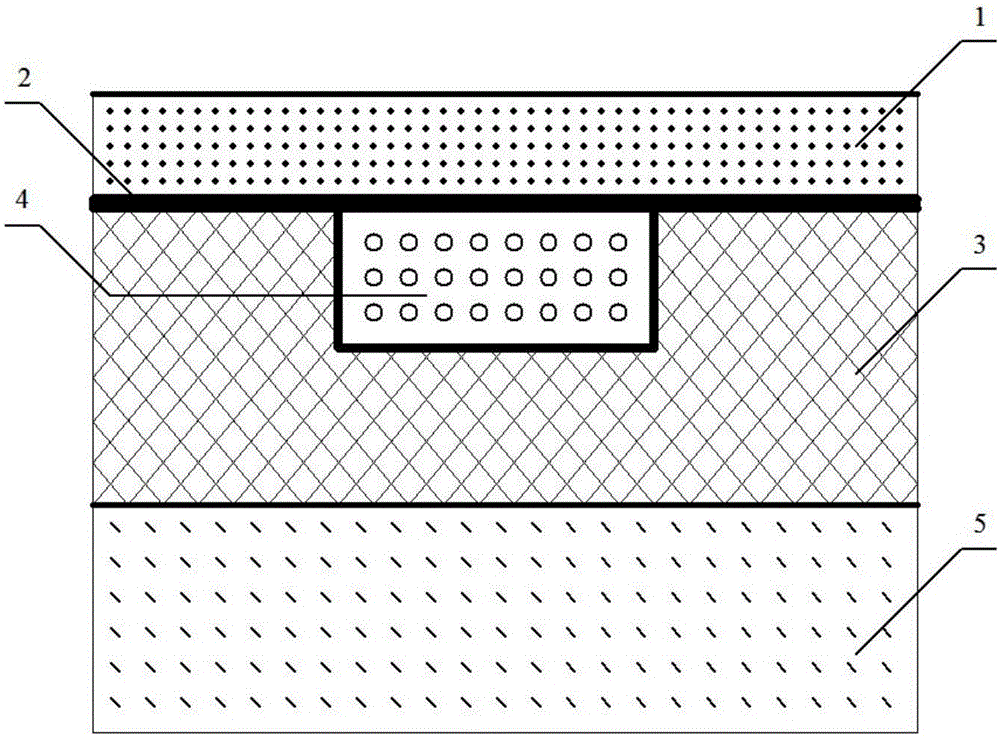

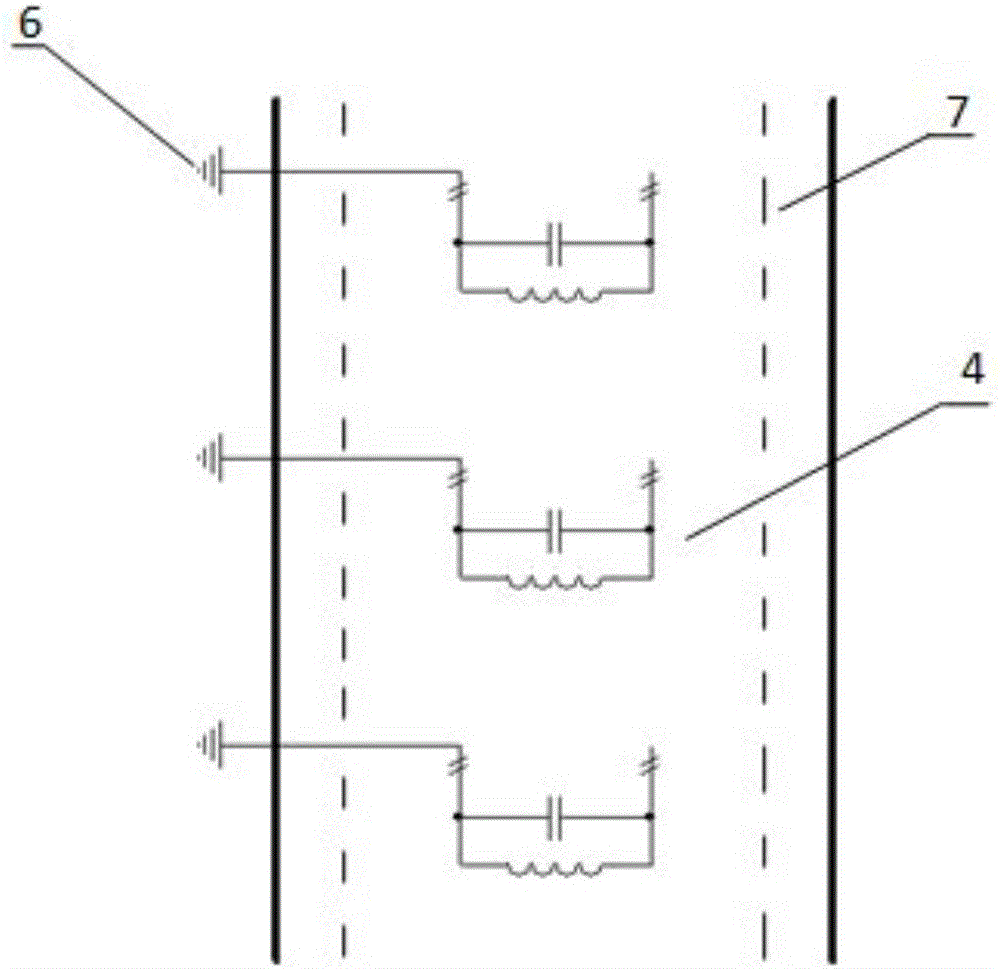

[0039] Example 3 is the above-mentioned natural basalt aggregate asphalt concrete, and example 4 is the above-mentioned natural basalt aggregate asphalt concrete specimen with a glass fiber grid with a grid size of 25 × 25 mm.

[0040] The anti-rutting performance indicators of the two asphalt concrete specimens are shown in Table 2. It can be seen from Table 2 that after the grid is added, the grid holes have a certain restraint effect on the aggregate, so that the anti-rutting performance of asphalt concrete can be increased by 30.4%. Due to the heat generated by the transmitting circuit, the temperature under the asphalt concrete seal is relatively high. Adding grids under the asphalt concrete seal can significantly enhance the high-temperature deformation resistance of the road surface under the action of vehicle loads, reduce the occurrence of road rutting, and at the same time The grid overlay is placed between the polymer concrete and the asphalt concrete, which also he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com