Cold-mixed and cold-laid asphalt mixture, and cold-mixed and cold-laid asphalt mixture wearing layer

A technology of cold-laying asphalt and mixture, which is applied to coagulating pavement, buildings, roads and other directions paved on site. It can solve the problems of reflective crack disease and weak performance of pending-reflective cracks, so as to prolong the expected life and improve construction production efficiency. , the effect of saving carbon emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

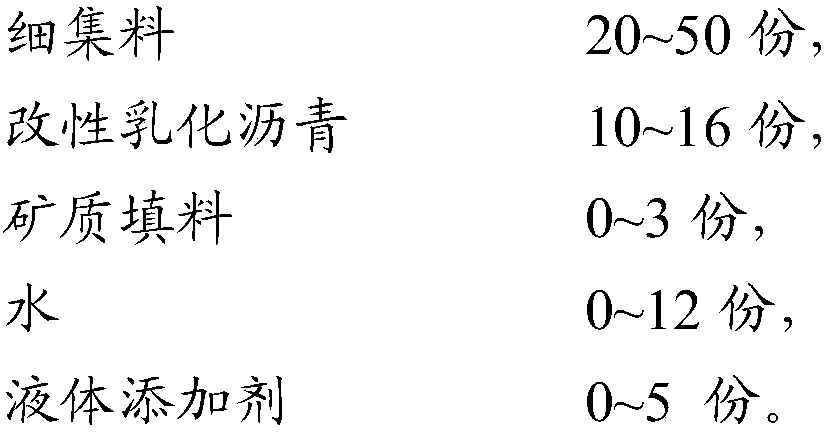

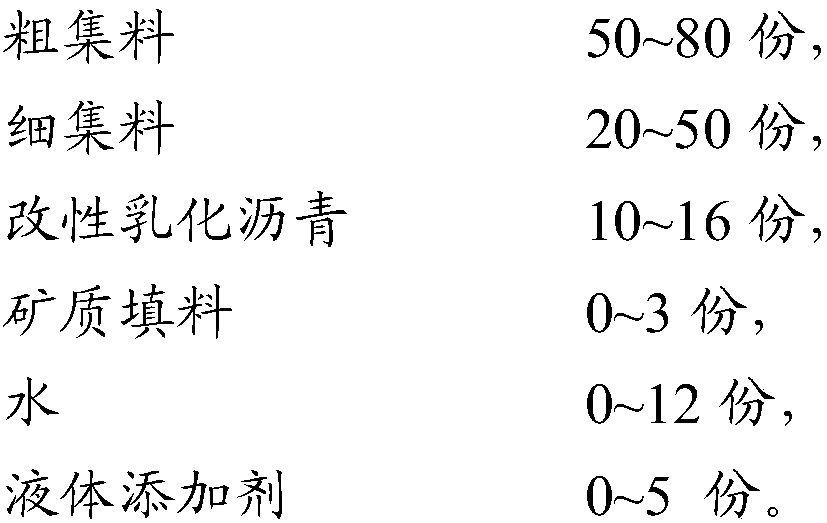

[0044]A cold-mixed asphalt mixture comprising the following components in parts by mass:

[0045] 60 parts of diabase coarse aggregate,

[0046] 40 parts of diabase fine aggregate,

[0047] 12 parts of SBS modified emulsified asphalt,

[0048] 1 part cement,

[0049] 3 parts water,

[0050] 0 parts of water-based coupling agent.

[0051] Among them, Portland cement is used for cement, pure water is used for water, the mass content of SBS modifier in modified emulsified asphalt is not less than 4%, and no water-based coupling agent is added. The particle size of the aggregate is 0-9.5 mm, and the gradation adopts the GT-7 type in the special gradation of coarse aggregate and fine aggregate shown in Table 1. The results of the aggregate screening test are shown in Table 2:

[0052] Table 2 Coarse aggregate and fine aggregate screening test results

[0053]

[0054] The construction method steps of cold-mixed and cold-laid asphalt mixture wear course are as follows:

[...

Embodiment 2

[0057] A cold-mixed asphalt mixture comprising the following components in parts by mass:

[0058] Granite coarse aggregate 80 parts,

[0059] Granite fine aggregate 20 parts,

[0060] 15 parts of SBS modified emulsified asphalt,

[0061] Mineral powder 0.5 part,

[0062] 0.5 parts of water,

[0063] 3 parts of water-based coupling agent.

[0064] Among them, the coarse aggregate and fine aggregate are acidic granite aggregates, the mass content of SBS modifier in the modified emulsified asphalt is not less than 4%, water-based coupling agent is added, and the particle size of the aggregate is 0-9.5mm. The GT-7 type in the special gradation of coarse aggregate and fine aggregate as shown in Table 1 is adopted, and the results of the aggregate screening test are shown in Table 3:

[0065] Table 3 Coarse aggregate and fine aggregate screening test results

[0066]

[0067] The construction method steps of cold-mixed and cold-laid asphalt mixture wear course are as follo...

Embodiment 3

[0070] A cold-mixed asphalt mixture comprising the following components in parts by mass:

[0071] Granite coarse aggregate 50 parts,

[0072] Granite fine aggregate 50 parts,

[0073] 10 parts of SBS modified emulsified asphalt,

[0074] 3 parts of cement,

[0075] 5 parts of water,

[0076] 1 part of water-based coupling agent.

[0077] Among them, the coarse aggregate and fine aggregate are acidic granite aggregates, the mass content of SBS modifier in the modified emulsified asphalt is not less than 4%, the particle size of the acidic aggregate is 0-9.5mm, and the gradation is as shown in the table The GT-5 type in the special gradation of coarse aggregate and fine aggregate shown in 1, the aggregate screening test results are shown in Table 4:

[0078] Table 4 Coarse aggregate and fine aggregate screening test results

[0079]

[0080] The construction method steps of cold-mixed and cold-laid asphalt mixture wear course are as follows:

[0081] Add the designed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pull-out strength | aaaaa | aaaaa |

| Pull-out strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com