Heat reflection fog sealing layer material, and anti-rut pavement structure for high temperature heavy duty conditions

A fog seal material and pavement structure technology, which is applied in the field of civil engineering, can solve problems such as the large proportion of organic substances, influence on popularization and use, and pollute the environment, and achieve the effects of good road performance, reasonable cost, and simple formula

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

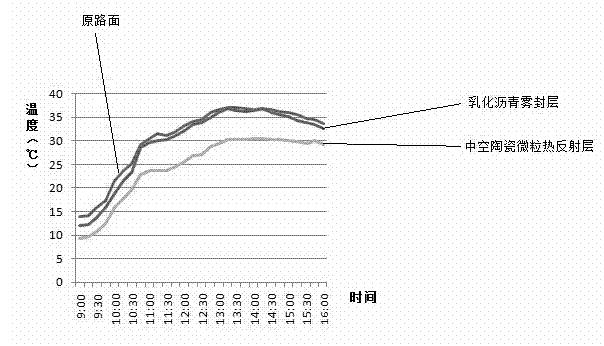

[0032]According to the ratio of parts by mass, take 1 part of hollow ceramic particles and 9 parts of emulsified asphalt, and mix the two evenly to obtain a heat-reflecting fog sealing layer material, which is conventionally sprayed on the surface of the upper layer 1 to form 35 L / m3 2 . The particle size of the ceramic particles is 100 μm.

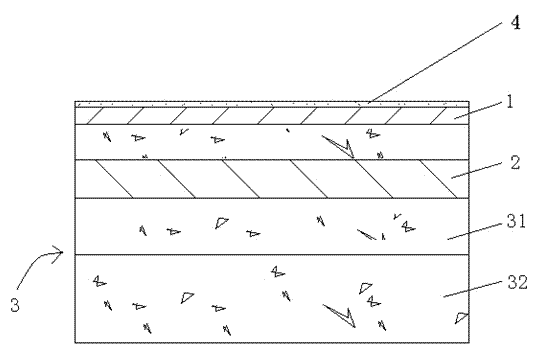

[0033] The surface of the upper layer 1 is coated with the anti-rutting pavement structure of the above-mentioned heat-reflecting mist sealing layer material, such as figure 1 As shown, the present invention includes an upper layer 1, a middle lower layer 2, and a base layer 3 from top to bottom. The upper layer 1 is the SMA-13 asphalt mixture layer, the middle and lower layer 2 is the HMAC-20 high modulus asphalt mixture layer, the base layer 3 is the LSAM large particle size asphalt mixture layer 31 and the cement stabilized macadam layer 32 .

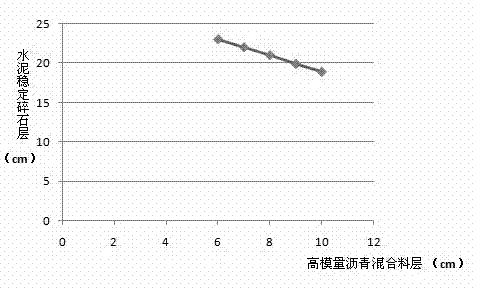

[0034] The thickness of the upper layer 1 is 4 cm, the thickness of the middle and low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com