Diatomite-based asphalt mixture high and low temperature modifier and preparation method thereof

A soil-based asphalt and mixture technology, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of limited improvement of high-temperature performance of asphalt mixture, no significant improvement of low-temperature performance, and influence on fatigue damage of asphalt pavement, etc., to achieve improvement Outstanding sexual effect, high cost performance, and remarkable cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

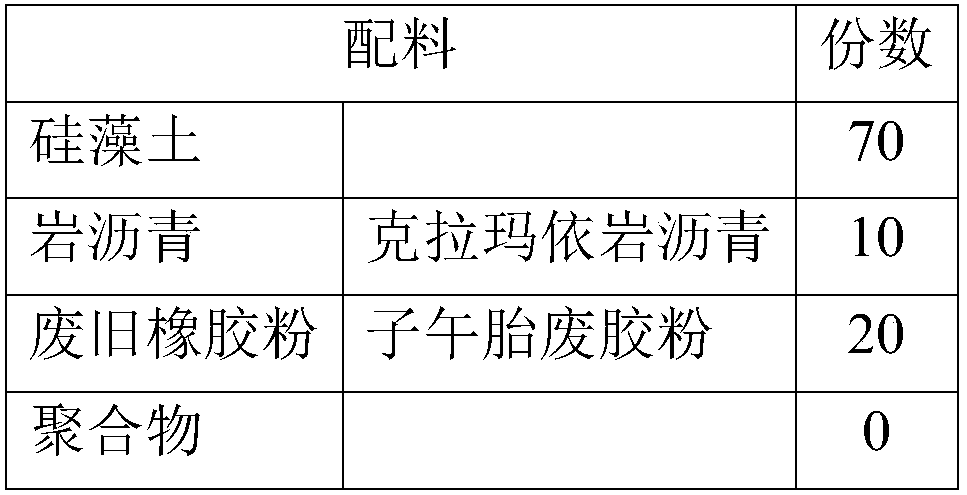

[0032] Preparation formula of diatomite-based asphalt mixture high and low temperature modifier:

[0033] Table 1. Formulation of one embodiment of a diatomaceous earth-based modifier according to the present invention

[0034]

[0035] Preparation:

[0036] 1) The diatomite raw ore is first crushed to a particle size of less than 40cm by a roller machine, and then enters the scrubbing machine through a conveyor belt. After scrubbing to form a slurry, it enters the slurry mixing tank through a pipeline, and uses a large agitator to stir the slurry. Separate the soil and sand, use a hydrometer to test the concentration of the slurry when it reaches 10-15%, then use a filter press to dry the slurry, and finally enter the dryer for drying. During drying, take samples to test the moisture content. When the moisture content When it is less than 5%, the diatomite is taken out from the dryer, which is high-purity activated diatomite;

[0037] 2) Weigh the high-purity activated d...

Embodiment 2

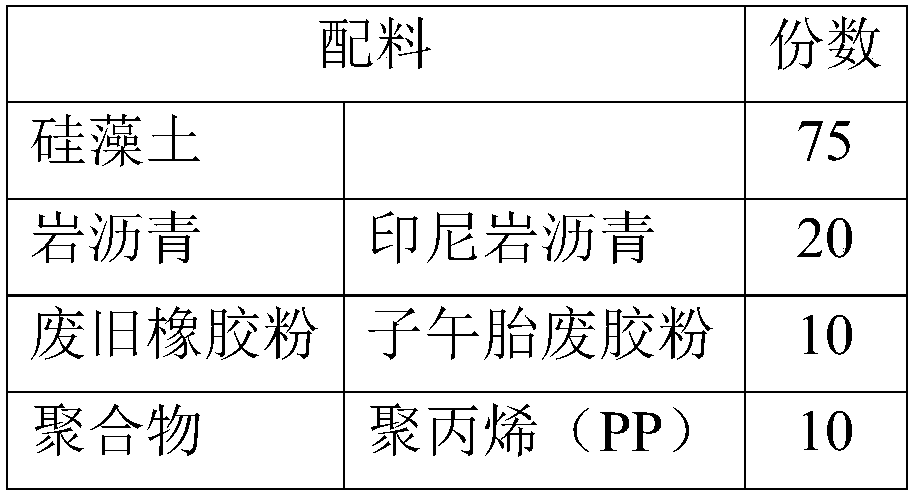

[0040] Preparation formula of diatomite-based asphalt mixture high and low temperature modifier:

[0041] Table 2. Formulation of another embodiment of a diatomaceous earth-based modifier according to the present invention

[0042]

[0043] Preparation:

[0044] Referring to the method of Example 1, the diatomite-based asphalt mixture high and low temperature modifier of this example was prepared.

Embodiment 3

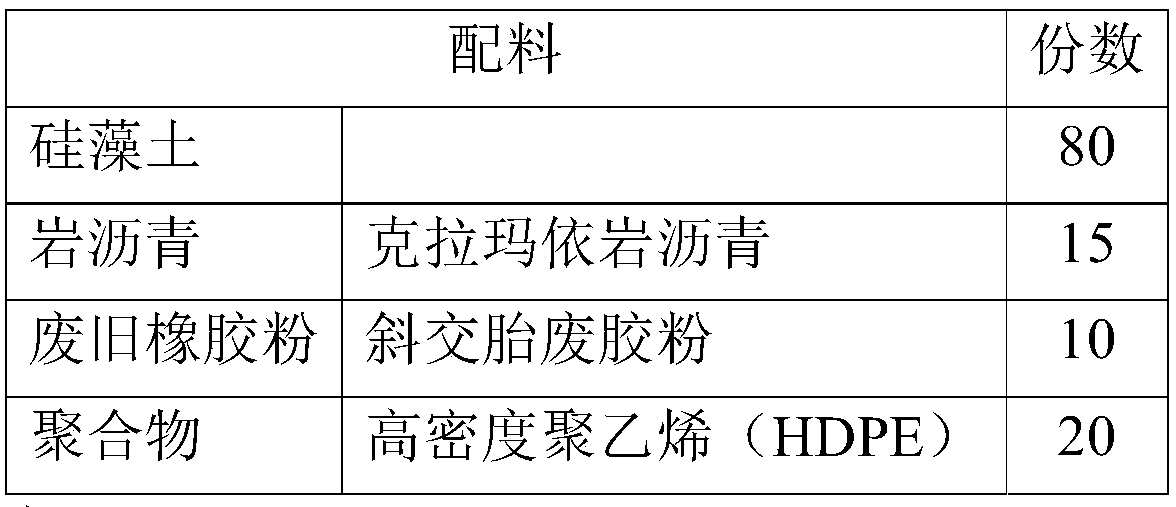

[0046] Preparation formula of diatomite-based asphalt mixture high and low temperature modifier:

[0047] Table 3. Formulation of another embodiment of a diatomaceous earth-based modifier according to the present invention

[0048]

[0049] Preparation:

[0050] Referring to the method of Example 1, the diatomite-based asphalt mixture high and low temperature modifier of this example was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com