Cooling pavement

A pavement and surface layer technology, applied to roads, roads, pavement details, etc., can solve the problems of high cost, complicated construction process, and limited effect of road surface temperature, etc., and achieve the effects of low cost, reduced rutting disease, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

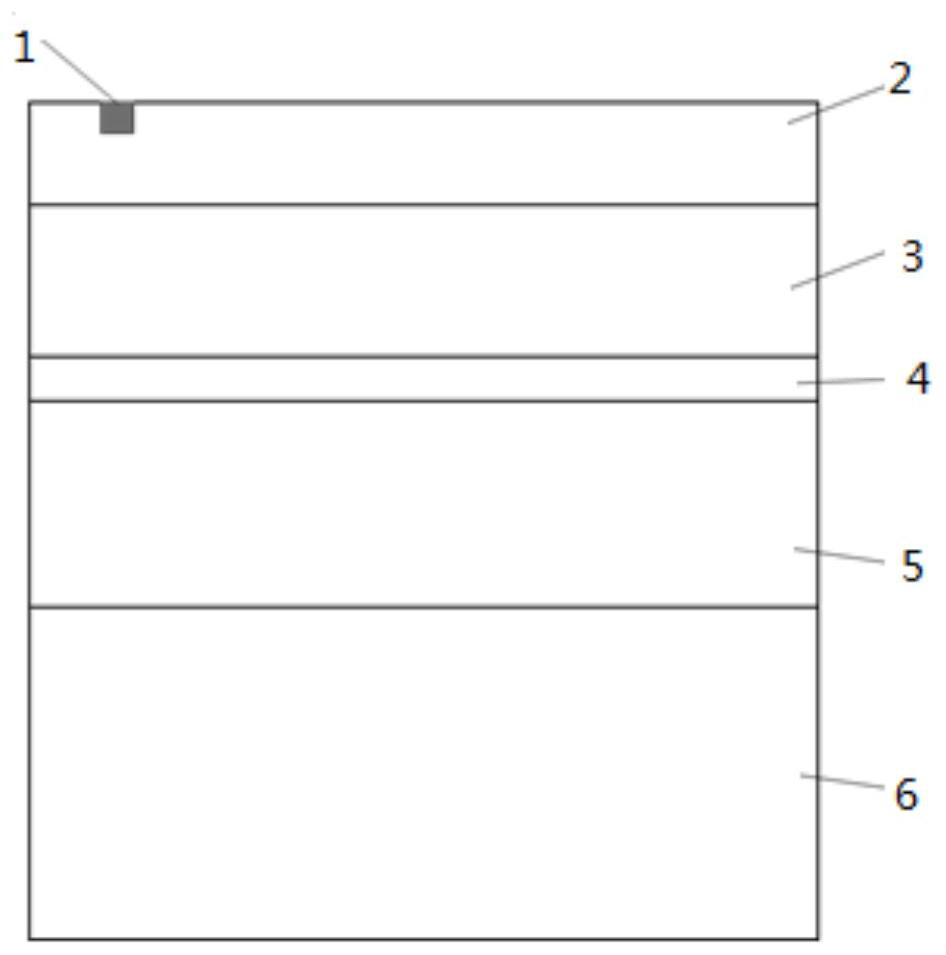

[0090] This embodiment provides a cooling road, please combine Figure 1 to 3 The cooling road surface is sequentially provided with the upper layer 2, the medium layer 3, the cooling structure layer 4, the lower layer 5, and the cement stabilized gravel base layer 6.

[0091] Among them, the asphalt mixture used in the upper layer 2 is SMA-13, the asphalt mixture used in the middle layer 3 is SUP-20, and the asphalt mixture used in the lower layer 5 is SUP-25. 20 wt% graphite fibers were added to the asphalt mixture of the upper layer 2 and the lower layer 5. The thickness of the upper layer 2 is 4 cm, and the thickness of the medium layer 3 is 6 cm, the thickness of the cooling structure layer 4 is 3 cm, the thickness of the lower layer 5 is 7 cm, and the thickness of the cement stabilized stone base layer 6 is 38 cm.

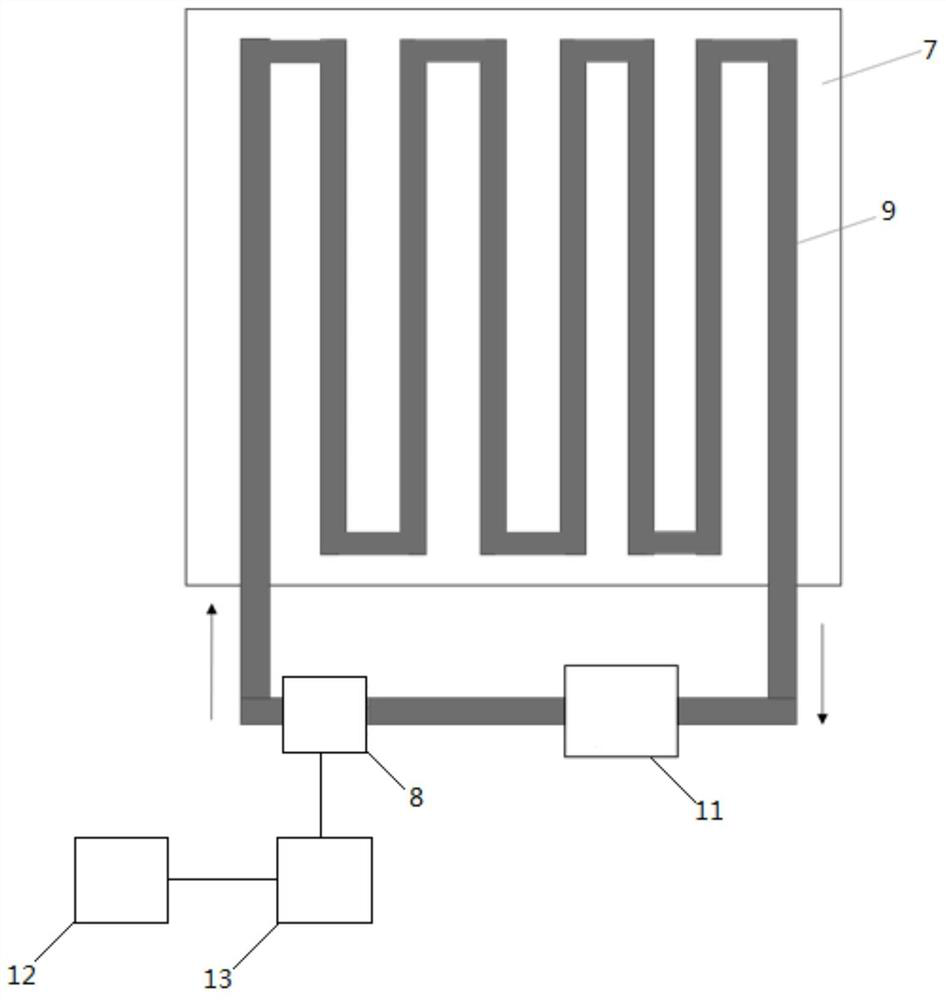

[0092] The cooling structure layer 4 is poured by the GA10 pouring asphalt mixture 7, and 20% by weight of graphite fibers are also added in the asphalt mixture. ...

Embodiment 2

[0102] The cooling pavement provided in this embodiment is as follows:

[0103] Among them, the asphalt mixture used in the upper layer 2 is a mixture of SUP-13 and AC-13, and the asphalt mixture used in the middle layer 3 is SUP-20 and AC-20 mixed materials, and the lower layer 5 is used. The asphalt mixture is a mixture of SUP-25 and AC-25. 25 wt% graphite powder was added to the asphalt mixture of the upper layer 2 and the lower layer 5. The thickness of the upper layer 2 is 3 cm, the thickness of the medium layer 3 is 7 cm, and the thickness of the lower layer 5 is 8 cm, the cement stabilized gravel base layer 6 has a thickness of 40 cm.

[0104] The asphalt mixture in the cooling structure layer 4 added 15% by weight of graphite powder. The oil ratio of the asphalt mixture in the cooling structure layer 4 is 7.8. The thickness of the cooling structure layer 4 is 2.5 cm.

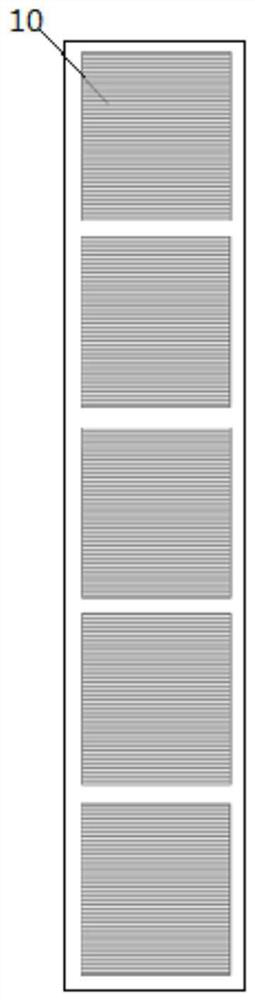

[0105] The cooling module 10 disposed in the cooling structure layer 4 is arranged along the driving dire...

Embodiment 3

[0109] The cooling pavement provided in this embodiment is as follows:

[0110] A mixture of 30% by weight of graphite fibers and carbon fibers (mixed ratio 1: 1) is added to the asphalt mixture of the upper layer 2 and the lower layer 5. The thickness of the upper layer 2 is 2.5 cm, the thickness of the middle layer 3 is 8 cm, the thickness of the lower layer 5 is 7.5 cm, and the thickness of the cement stabilized gravel base layer 6 is 39 cm.

[0111] The asphalt mixture in the cooling structure layer 4 adds 25% by weight of graphite fibers and mixtures of carbon fibers (mixed ratio 1: 1). The oil ratio of the asphalt mixture in the cooling structure layer 4 is 8.3. The thickness of the cooling structure layer 4 is 2.8 cm.

[0112] The length of each of the cooling modules 10 is 18 m. The thermally conductive tubes 9 in each of the cooling modules 10 are serpeted in the travel direction (longitudinal). The material of the heat transfer tube 9 is a steel, and the heat conductive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com