A kind of anti-aging soluble rubber powder modified asphalt and preparation method thereof

A modified asphalt and solubility technology, applied in building components, building thermal insulation materials, construction and other directions, can solve the problems of insufficient compatibility of rubber powder in asphalt, high cost, long time consumption, etc., to extend life, reduce contact, The effect of reducing segregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment is a soluble rubber powder modified asphalt with excellent anti-aging performance, specifically a new type of soluble rubber powder modified asphalt that is resistant to thermo-oxidative aging and ultraviolet aging.

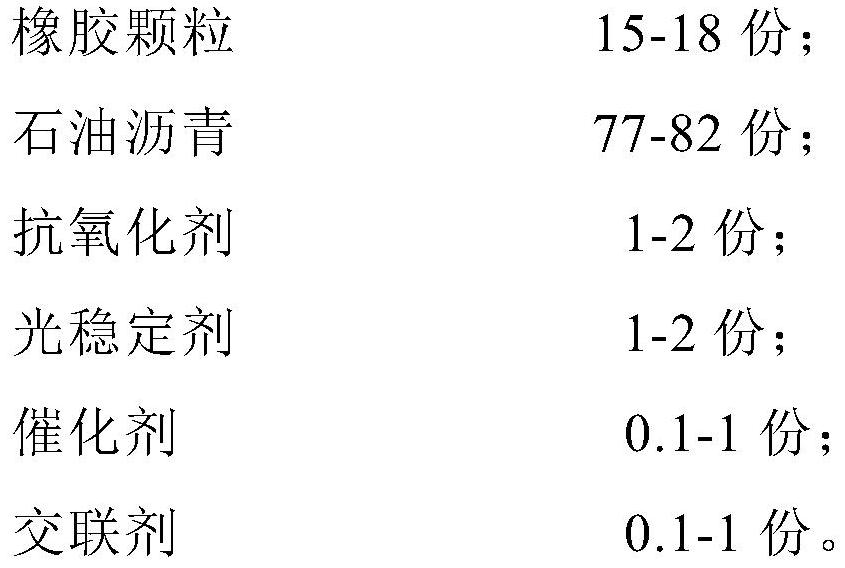

[0055] The soluble rubber powder modified asphalt with excellent aging resistance is prepared from the following raw materials in parts by weight:

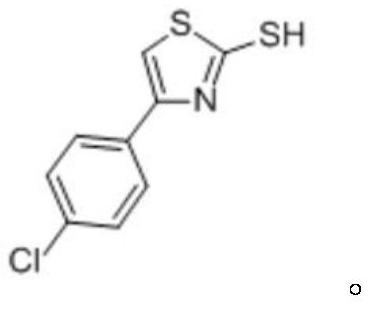

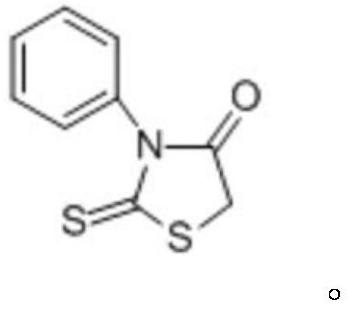

[0056] 16 parts of 80 mesh rubber particles, 81 parts of petroleum asphalt, 1 part of antioxidant tris(2,4-di-tert-butylphenyl) phosphite, 1 part of light stabilizer 2-hydroxy-4-methoxybenzophenone , 0.5 parts of catalyst 4-(4-chlorophenyl)-4-thiazoline-2-thione, 0.5 parts of crosslinking agent 3-phenyl-2-thione-1,3-thiazoline-4-one, Wherein, the petroleum asphalt is a straight-run asphalt, the sum of the saturated content and the aromatic content in its components is between 50%, and the saturated content is less than 18%.

[0057] Prepare soluble rubber powder modified asphalt with excellent...

Embodiment 2

[0063] This embodiment is a soluble rubber powder modified asphalt with excellent anti-aging performance, specifically a new type of soluble rubber powder modified asphalt that is resistant to thermo-oxidative aging and ultraviolet aging.

[0064] Soluble rubber powder modified asphalt with excellent anti-aging performance is prepared from the following raw materials in parts by weight: 15 parts of 80-mesh rubber particles, 82 parts of petroleum asphalt, antioxidant tris(2,4-di-tert-butylphenyl ) ester 1 part, light stabilizer 2-hydroxy-4-methoxybenzophenone 1 part, catalyst 4-(4-chlorophenyl)-4-thiazoline-2-thione 0.5 part, crosslinking agent 0.5 parts of 3-phenyl-2-thione-1,3-thiazolin-4-one.

[0065] The preparation method is the same as in Example 1.

Embodiment 3

[0067] This example is a soluble rubber powder modified asphalt with excellent anti-aging performance, specifically a new soluble rubber powder modified asphalt that is resistant to thermo-oxidative aging and ultraviolet aging.

[0068] The soluble rubber powder modified asphalt with excellent aging resistance is prepared from the following raw materials in parts by weight:

[0069] 18 parts of 80 mesh rubber particles, 79 parts of petroleum asphalt, 1 part of antioxidant tris(2,4-di-tert-butylphenyl) phosphite, 1 part of light stabilizer 2-hydroxy-4-methoxybenzophenone , 0.5 part of catalyst 4-(4-chlorophenyl)-4-thiazoline-2-thione, 0.5 part of crosslinking agent 3-phenyl-2-thione-1,3-thiazoline-4-one.

[0070] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com