Hot recycling method of asphalt mixing materials and hot recycling device of asphalt mixing materials

A technology of asphalt mixture and thermal regeneration, applied in roads, road repair, roads, etc., can solve the problems of poor adhesion between new aggregate and new asphalt, prolong time, waste asphalt, etc., to shorten mixing time, ensure Road performance, the effect of improving production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below through specific embodiments.

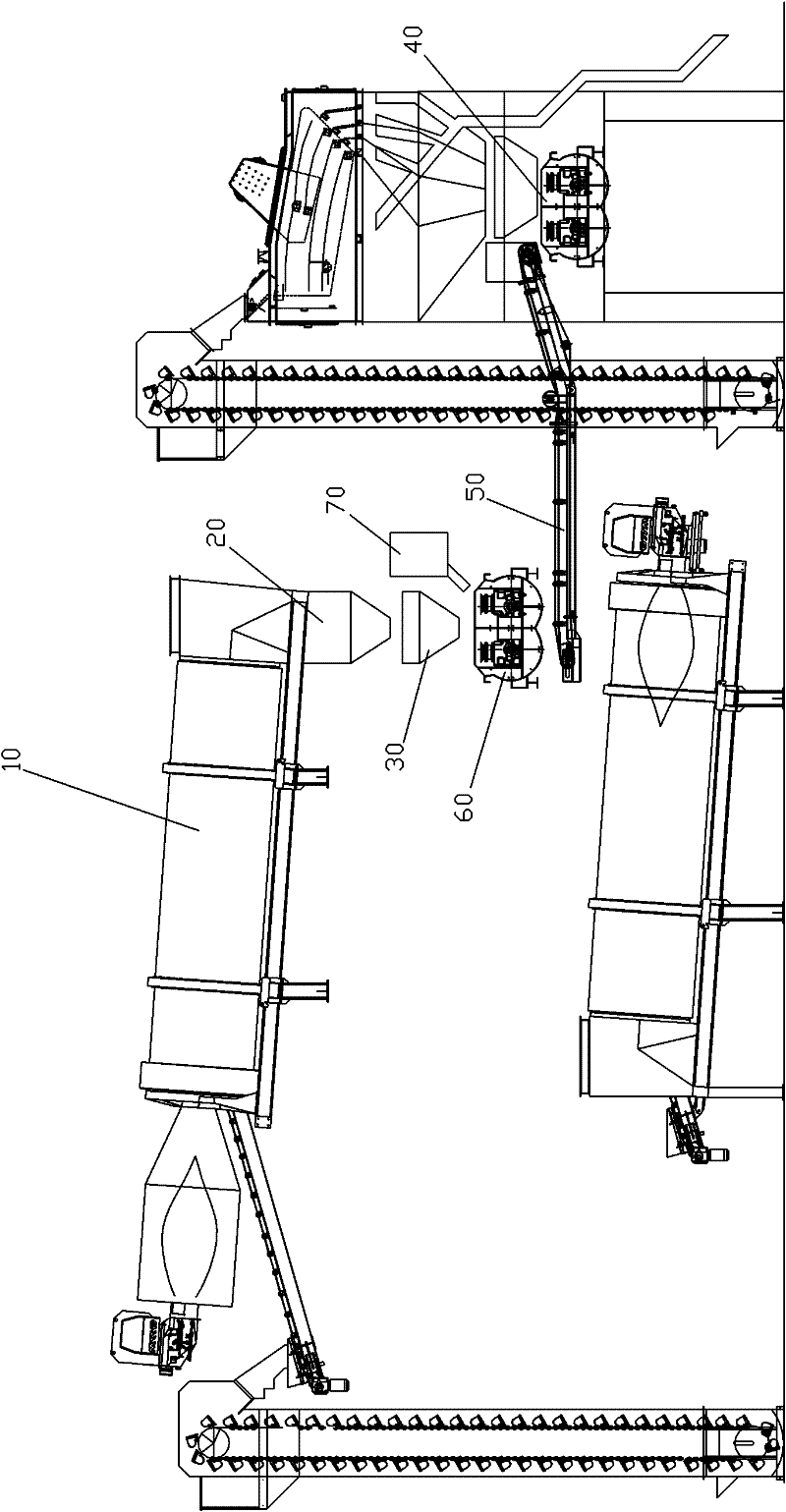

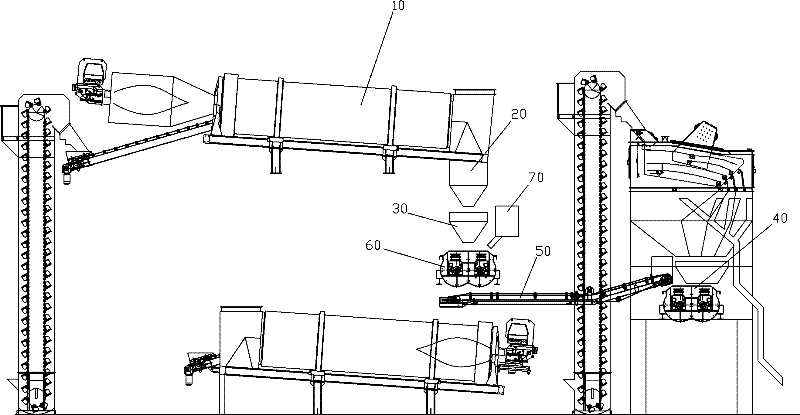

[0018] refer to figure 1 , a kind of asphalt mixture factory mixing heat regeneration equipment of the present invention includes a recycled material heating system 10, a recycled material storage bin 20 located behind the recycled material heating system 10, and a regeneration unit located below the recycled material storage bin 20 Material metering hopper 30, main mixing tank 40, and hot recycled material conveying belt 50 for sending hot recycled material into the main mixing tank 40, and a recycled material mixing tank 60 is provided below the recycled material measuring hopper 30, and the recycled material is stirred A regenerant metering bucket 70 is also provided above the cylinder 60 .

[0019] A kind of asphalt mixture factory mixing heat regeneration process of the present invention comprises the following steps:

[0020] The pretreatment and metering steps of new stone pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com