Low-odor rubber asphalt mixture used for road engineering

A technology for rubber asphalt and road engineering, applied in the field of auxiliary materials used in road engineering, can solve the problems of reducing the adhesion between asphalt and aggregates, difficult to form foamed asphalt, etc., to reduce adverse effects, effectively absorb, and increase the amount of mixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

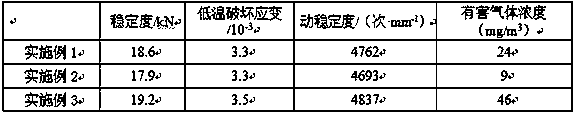

Examples

Embodiment 1

[0026] Example 1 Preparation of common warm-mix rubber asphalt mixture without zeolite

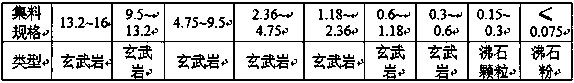

[0027] There are 100 parts of aggregate and mineral powder in total, the particle size distribution conforms to the median value of the SMA-13 gradation range in the specification, and all aggregates are made of basalt. The different specifications and types of aggregates and mineral powders are shown in Table 1. 5.5 parts of rubber asphalt, 0.3 parts of warm mix agent Cecabase RT.

[0028] Table 1 Specification distribution of aggregate and mineral powder of ordinary warm mix rubber asphalt mixture

[0029]

[0030] When preparing, first preheat the aggregate and mineral powder to 160~170°C, and keep it warm at this temperature for 3 hours; preheat the rubber asphalt to 145~155°C; add the aggregate, warm mixing agent and rubber asphalt to the mixing pot in turn In the process, mix at 150~155°C for 90s, then add mineral powder and continue to mix for 90s to obtain ordinary warm-mix ...

Embodiment 2

[0031] Example 2 Preparation of the low-odor rubber asphalt mixture of the present invention

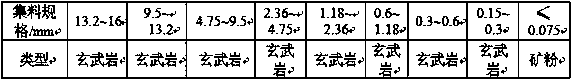

[0032] Aggregate, zeolite particles and zeolite powder total 100 parts, the particle size of zeolite particles is 0.15~0.3mm, and the particle size of zeolite powder is less than 0.075mm. The aggregates are all basalt. The corresponding particle size distribution of aggregates, zeolite particles and zeolite powder conforms to the median value of the SMA-13 grading range in the specification. The different specifications and types of aggregates, zeolite particles and zeolite powder are shown in Table 2. 5.5 parts of rubber asphalt, 0.3 parts of warm mix agent Cecabase RT.

[0033] Table 2 Specification distribution of aggregate and zeolite in environment-friendly and low-odor rubber asphalt mixture

[0034]

[0035] During preparation, the zeolite granules and zeolite powder are firstly pretreated: the zeolite granules and zeolite powder are placed in a vacuum drying oven, kep...

Embodiment 3

[0037] Example 3 Preparation of ordinary rubber asphalt mixture.

[0038] There are 100 aggregates and mineral powders in total, and their particle size distribution conforms to the median value of the SMA-13 gradation range in the specification. All aggregates are made of basalt. The different specifications and types of aggregates and mineral powders are shown in Table 1. 5.5 parts of rubber asphalt.

[0039] When preparing, first preheat the aggregate to 180~190°C, and keep it warm at this temperature for 3 hours; preheat the rubber asphalt to 165~175°C; add the aggregate and rubber asphalt to the mixing pot, Stir for 90 seconds, and finally add mineral powder and continue stirring for 90 seconds to obtain ordinary rubber asphalt mixture.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com