Tunnel ditch cover plate

A cover plate and side ditch technology, applied in waterway systems, drainage structures, water supply devices, etc., can solve the problems of cumbersome cover plate construction process, traffic interruption, tunnel water accumulation, etc., and achieve convenient construction, not easy to jump cover, and convenient construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

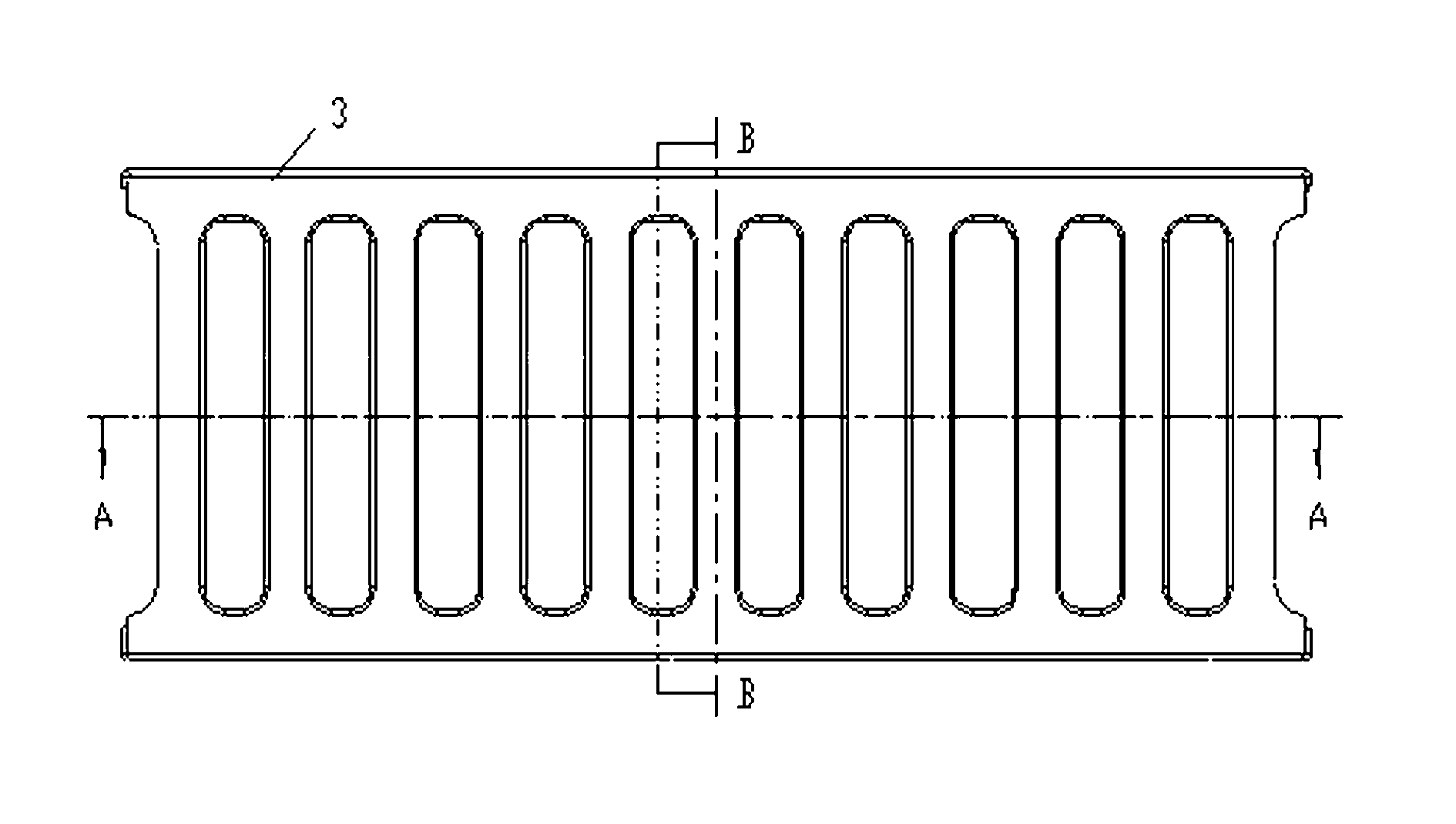

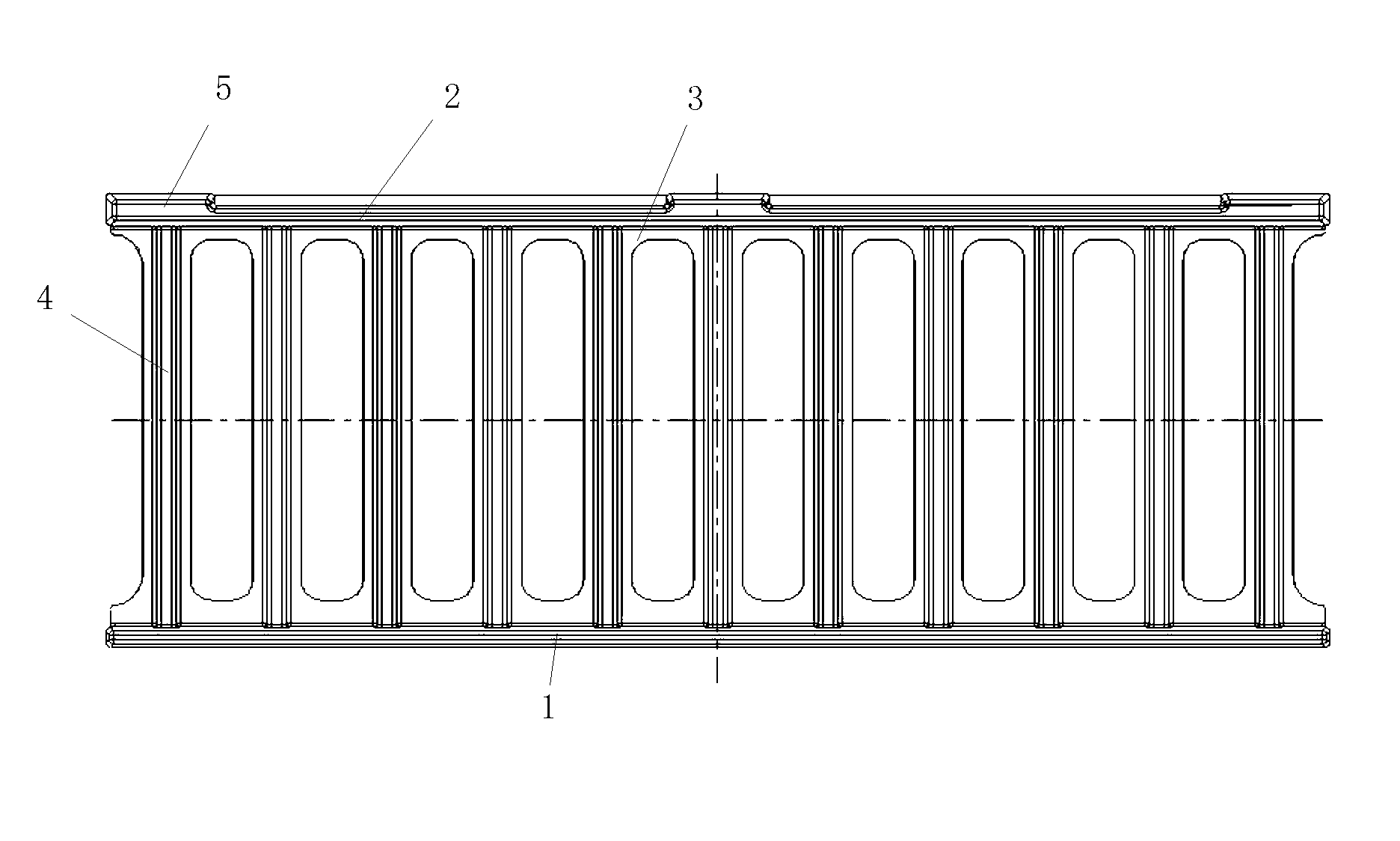

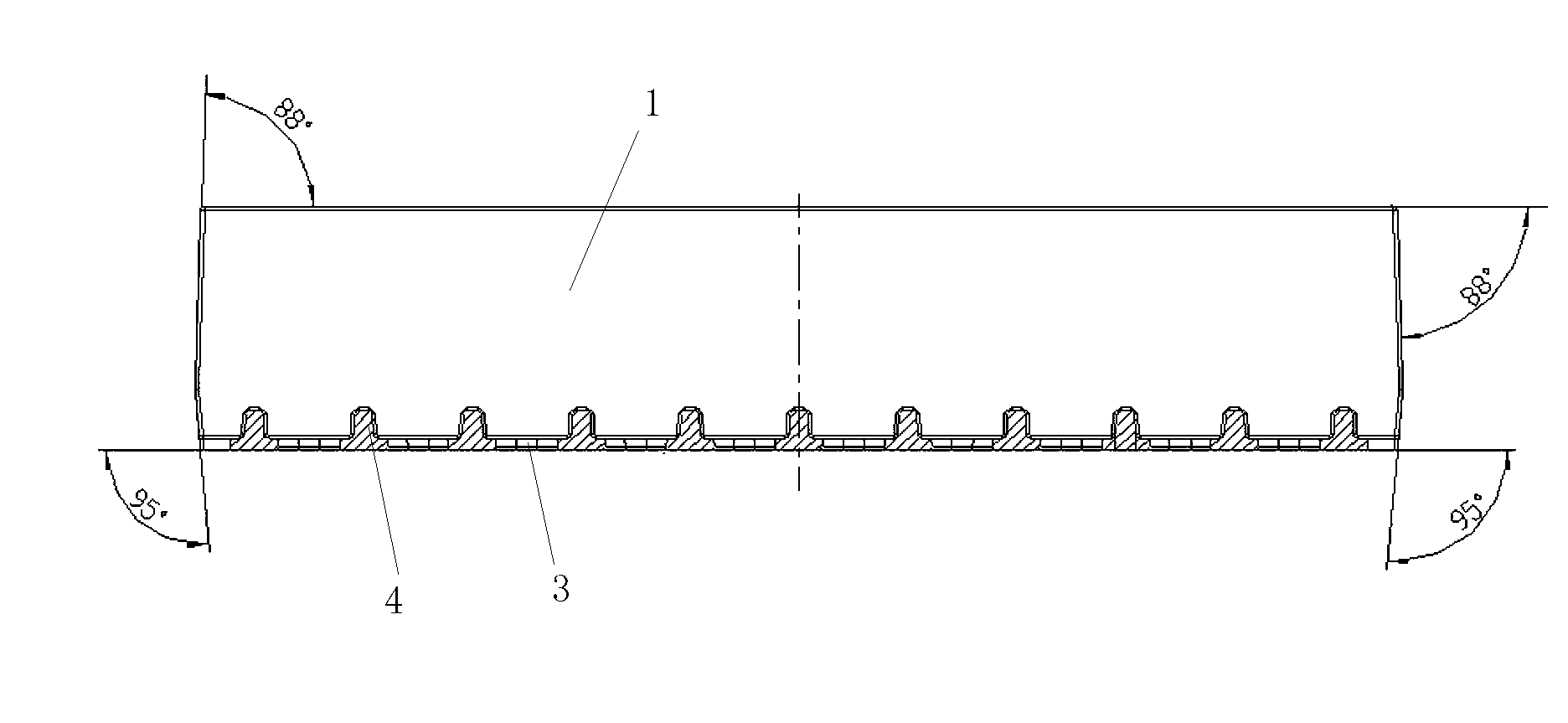

[0018] A tunnel gutter cover plate is characterized in that a first dedendum 1 is provided at the bottom of one side of the cover plate, and a second dedendum 2 is provided at the bottom of the other side. The material of the side ditch cover plate is ductile iron.

[0019] As shown in the figure, the material of this side ditch cover plate is ductile iron, and the cross-sectional shape is tooth-shaped. The two tooth roots can firmly support the cover plate and stick to the side wall of the tunnel box and the pavement layer. Embedded parts and blocks are set in the side ditch.

[0020] There are two types of toothed side ditch covers, one is the fixed upper and lower parts (referred to as the fixed cover), and the other is the openable type with the lower part and the frame fixed upper grille (referred to as the openable cover). For the convenience of dredging and maintenance, the two types of cover plates can be used in combination. For example, every 3~5 fixed types can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com