Tunnel center drainage ditch formwork assembly, drainage ditch structure and construction method of tunnel center drainage ditch formwork assembly

A tunnel center and drainage ditch technology, applied in drainage, earthwork drilling, safety devices, etc., can solve problems such as easy leakage at the drainage ditch interface, and achieve the effect of solving leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

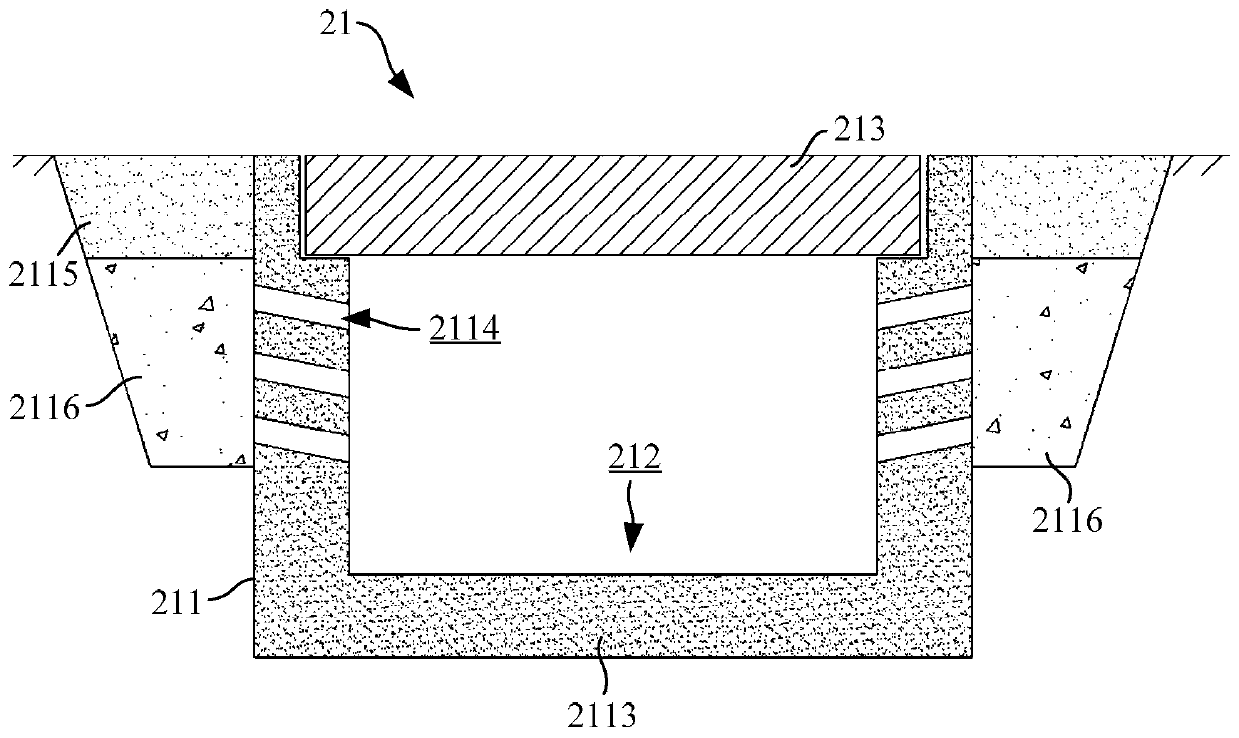

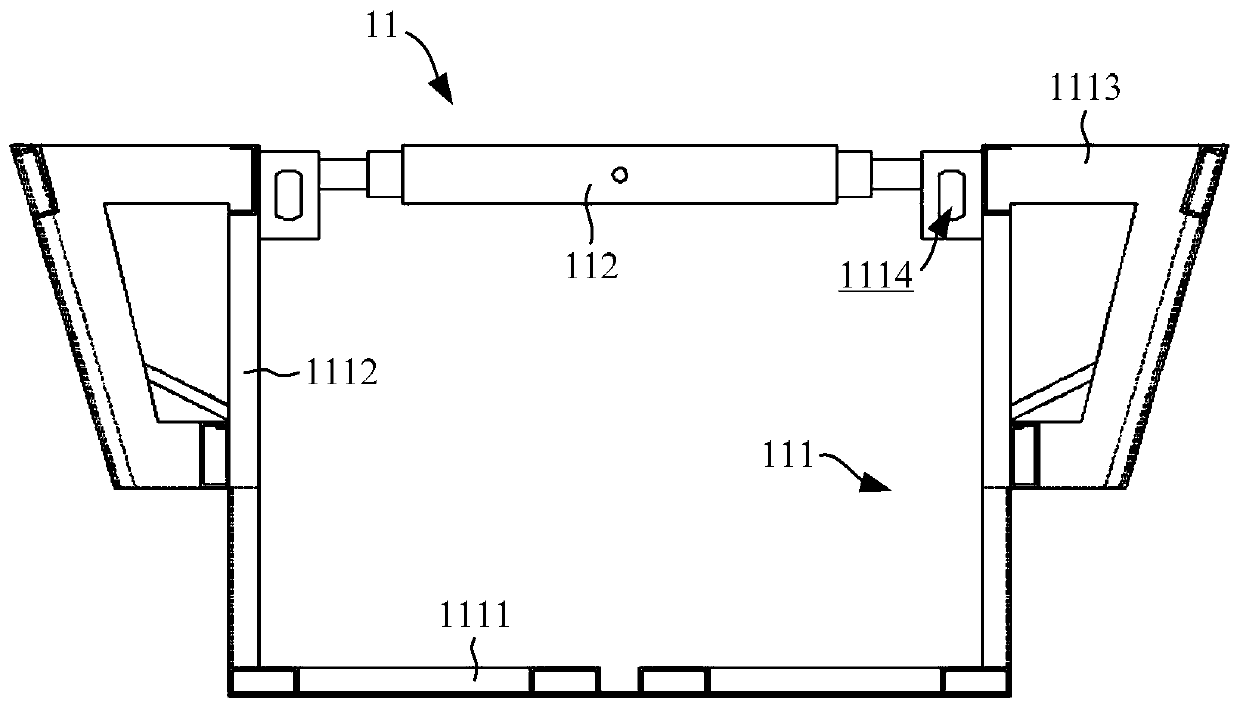

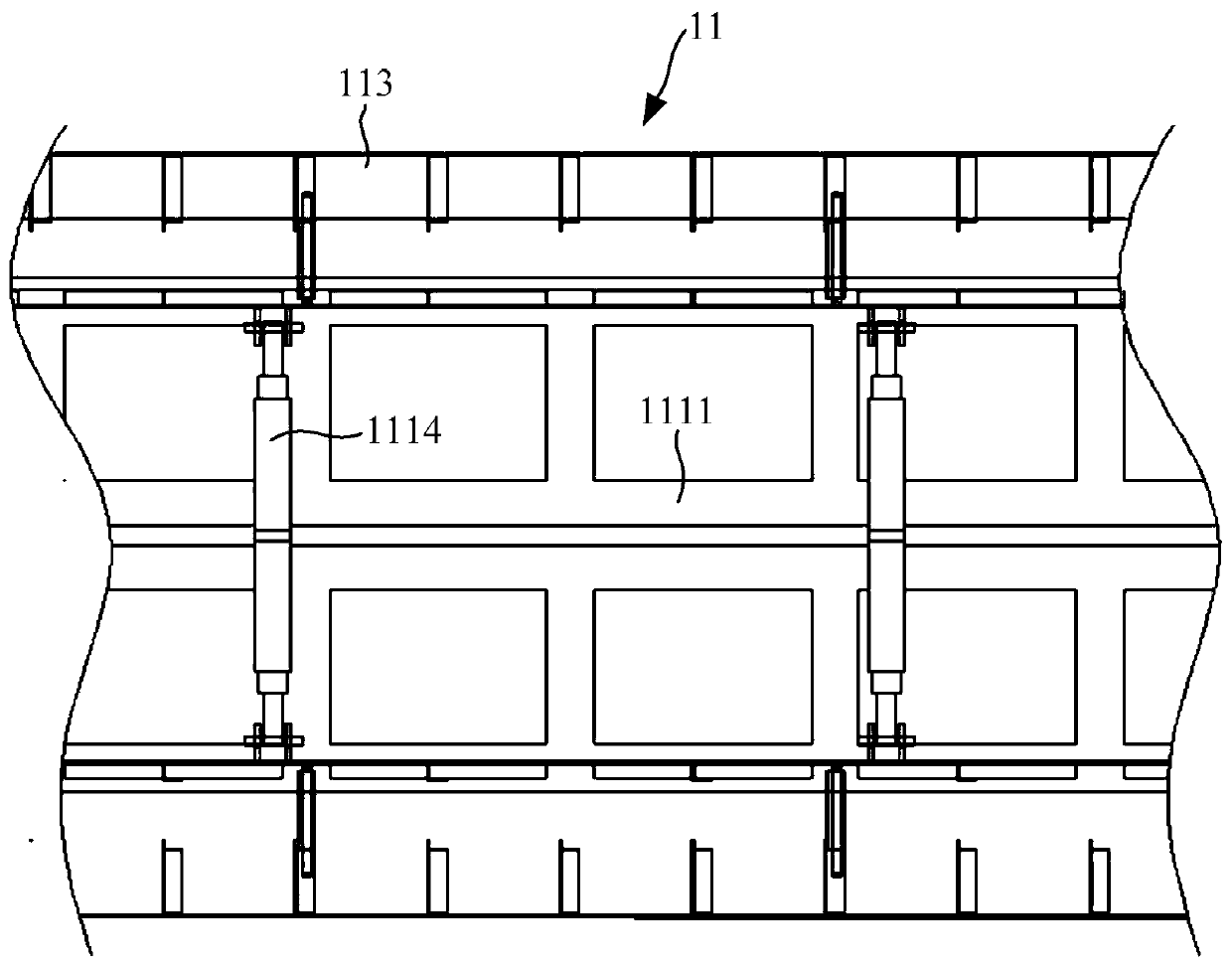

[0076] Place the outer formwork 11 on the center line of the pouring space of the tunnel substrate, and pour the outer formwork 11, so that a drainage ditch construction space 211 with the same cross-sectional shape as the outer formwork 11 is formed on the invert of the tunnel;

[0077] Adjust the length of the first screw mandrel 112 to reduce the distance between the two opposite first stoppers 111, so that the outer template 11 is taken out from the drainage ditch construction space 211;

[0078] After the drainage ditch construction space 211 is condensed, a frame body is placed at the bottom of the inner side of the drainage ditch construction space 211. The height of the frame body is equal to the design distance between the bottom of the drainage ditch 212 and the bottom of the drainage ditch construction space 211. On the frame, a partition plate is placed near the side space 2112 to the main space 2111 to separate the main space 2111 and the side space 2112, so as to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com