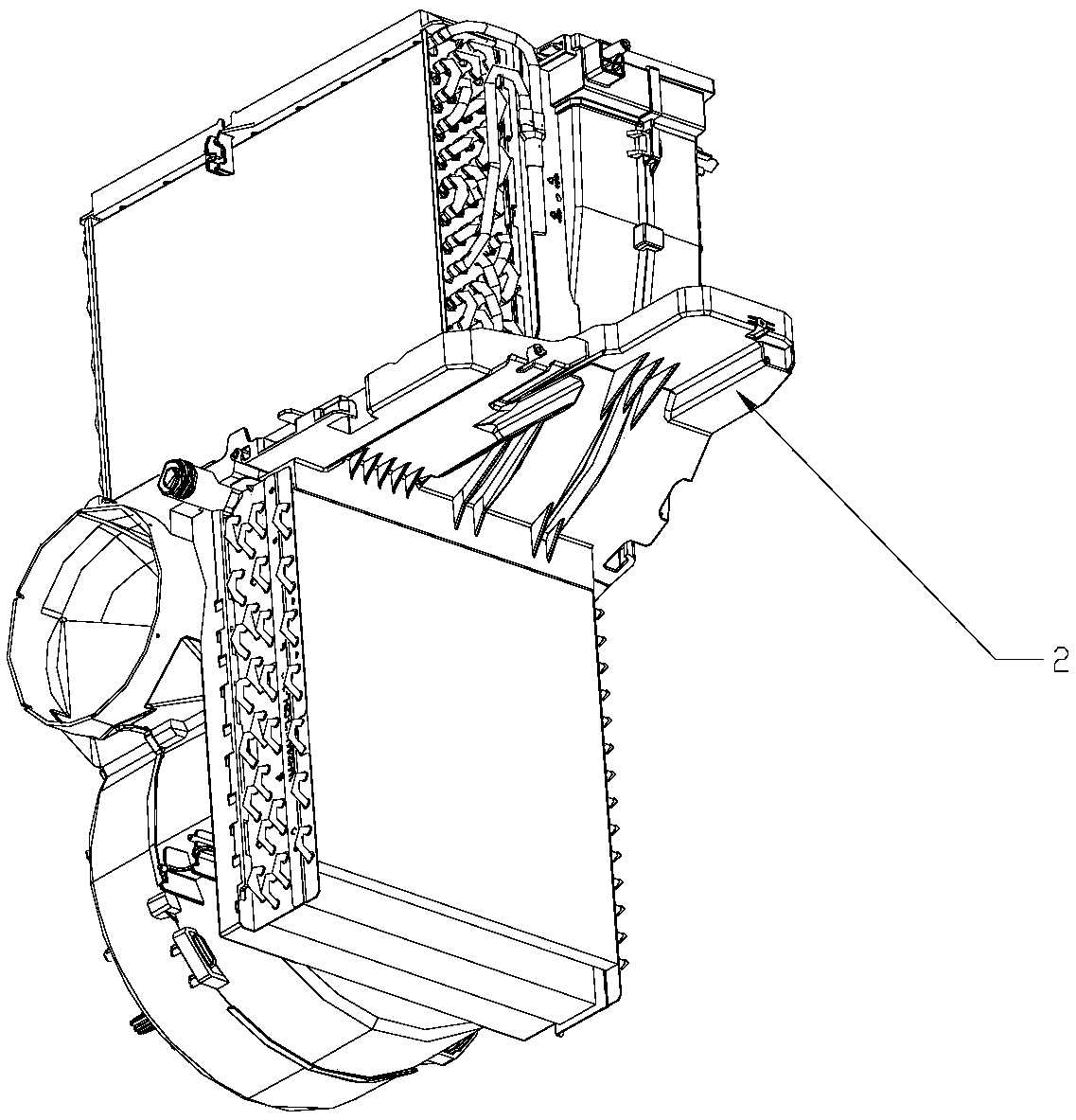

Middle-layer water receiving disc and mobile air conditioner with water receiving disc

A water-receiving pan and middle-layer technology, which is used in household appliances, prevention of condensation, space heating and ventilation details, etc., can solve problems such as insufficient drainage capacity of partitions, improve water removal efficiency, relieve water pressure, and expand Application-wide effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

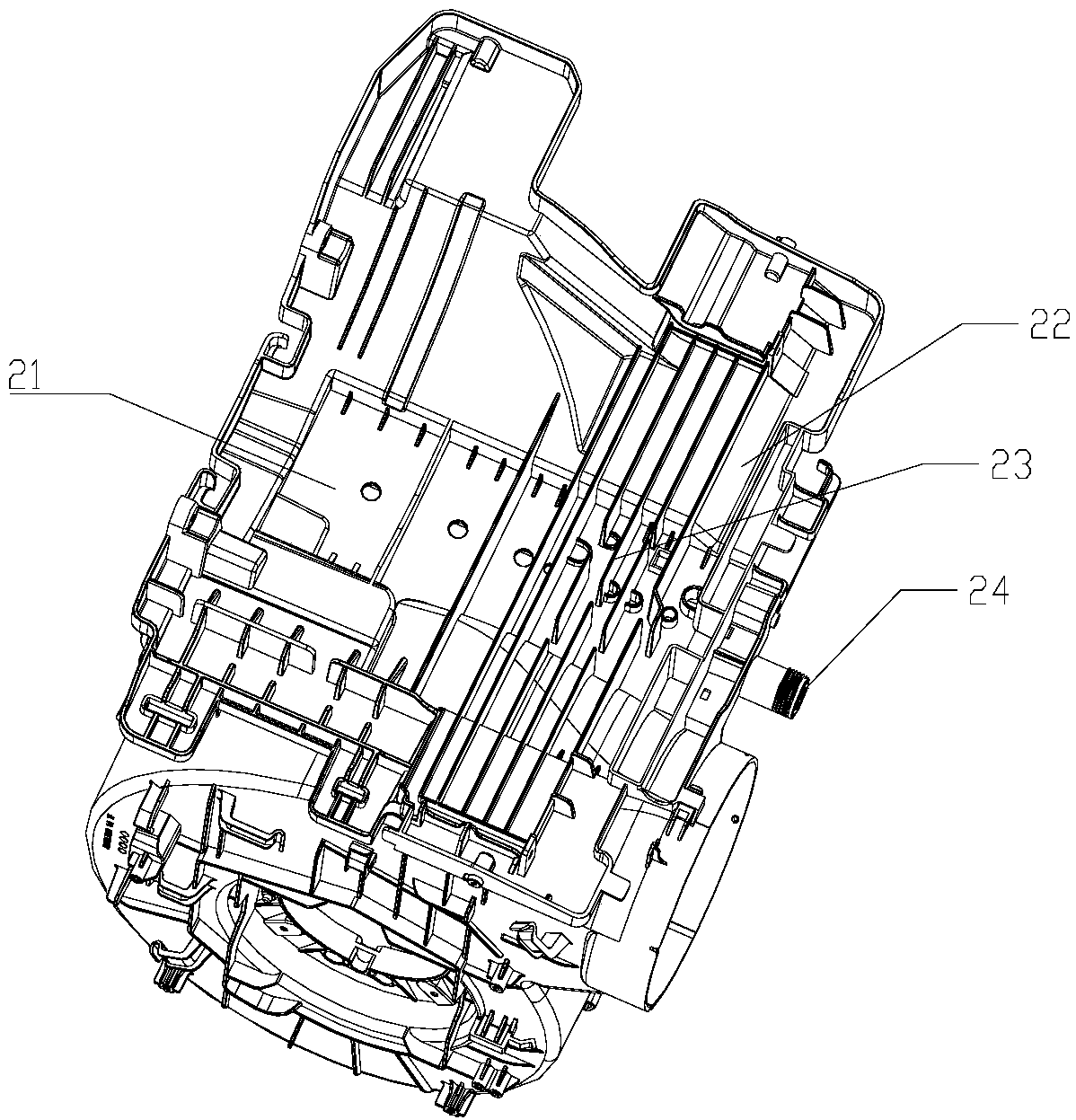

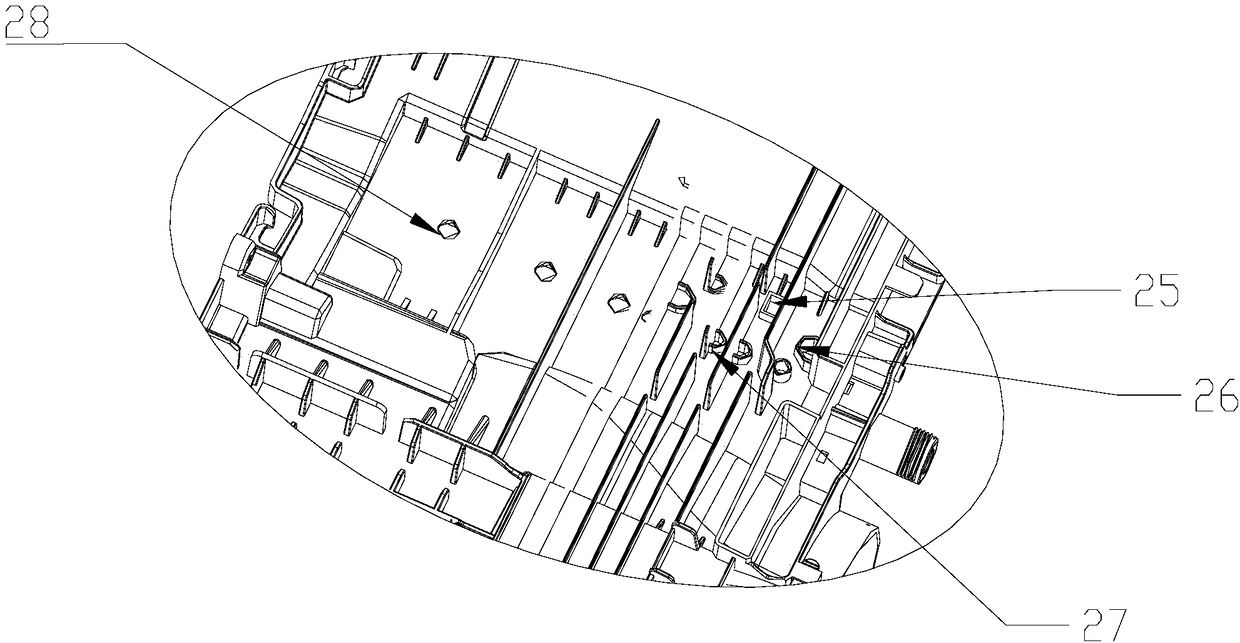

[0054] Among the present invention, the drain hole is arranged on the evaporator area 21, such as image 3 As shown, a cofferdam is provided on the drain hole, and the drain hole is divided into a first class drain hole 25, a second class drain hole 26 and a third class drain hole 27 according to the different heights of the cofferdam.

[0055] Such as Figure 4 As shown, the first type of drainage hole 25 is set as a square hole, and the first type of drainage hole 25 also includes a first cofferdam 251 and a first guide slope 252, and extends upward to a certain height along the square hole to form the first cofferdam 251. The height of the first cofferdam 251 is preferably set to 5mm-7mm, more preferably set to 7mm; the first guide slope 252 is inclined downward along the side of the square hole, and the first guide slope 252 is connected to the middle partition 2 and the first The integrated arrangement of the cofferdam 251 not only simplifies the manufacturing process, b...

Embodiment 2

[0062] The difference between the present embodiment and the first embodiment is that the first type of drain hole 25 is arranged close to other parts on the middle partition 2, that is, the cross-sectional shape of the top of the first cofferdam 251 is set as U-shaped, which is due to the In the first embodiment, the cross section of the first cofferdam 251 is in the shape of a "mouth". When the side walls of other components act as one side of the first cofferdam 251, the U-shaped cross section of the first cofferdam 251 and the side walls of other components together form a Closed "mouth" shape. In this embodiment, it is preferable to set a type of drain hole 25 on one side of the supporting rib 23, so that the supporting rib 23 can serve as one side of the first cofferdam 251. Such setting can not only save materials and reduce production costs, but also can This avoids the problem that the slit space is easily blocked due to arranging a type of downhole 25 between two row...

Embodiment 3

[0065] The difference between this embodiment and Embodiment 1 is that, as Figure 6 As shown, the fourth cofferdam 263 is formed by extending obliquely upwards around the first orifice 261, wherein the inclination angle is 3°-5° to the outside, so that the fourth cofferdam 263 forms an arc-shaped space with a wide top and a narrow bottom. Similarly, a fifth cofferdam is formed around the second orifice obliquely upward and outward by 3°-5°, so that the fifth cofferdam forms an arc-shaped space with a wide top and a narrow bottom.

[0066] The cofferdams on the second-type downholes 26 and the third downholes 27 are set in a shape that expands from bottom to top to the outside, which is beneficial for condensed water to enter the downholes. In addition, the expanded cofferdams can increase the capacity of the arc-shaped space. And the setting of the cofferdam with a wide top and a narrow bottom is conducive to increasing the water flow pressure, and can promote the rapid passa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com