A shoulder widening method for existing railway embankment

A technology with existing railways and road shoulders, applied to roads, roads, buildings, etc., can solve the problems of high construction cost, long construction period, and large excavation volume, and achieve low construction cost, reduced construction period, and small disturbance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

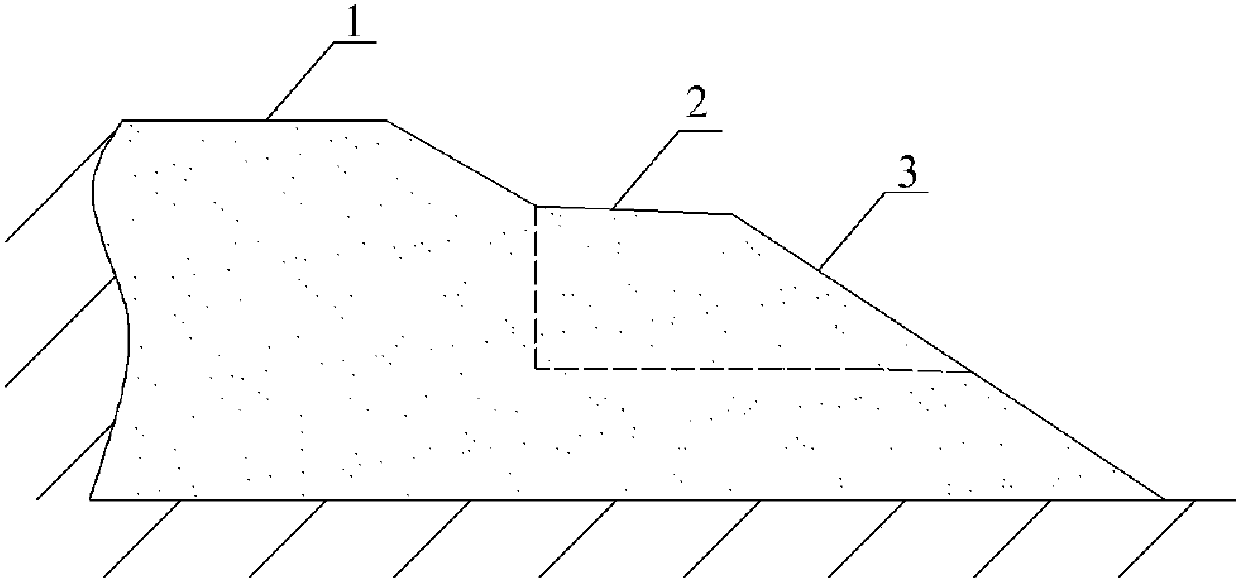

[0023] Figure 1-4 Shown, a kind of embodiment of the present invention is, a kind of road shoulder widening method of existing railway embankment, and its steps are:

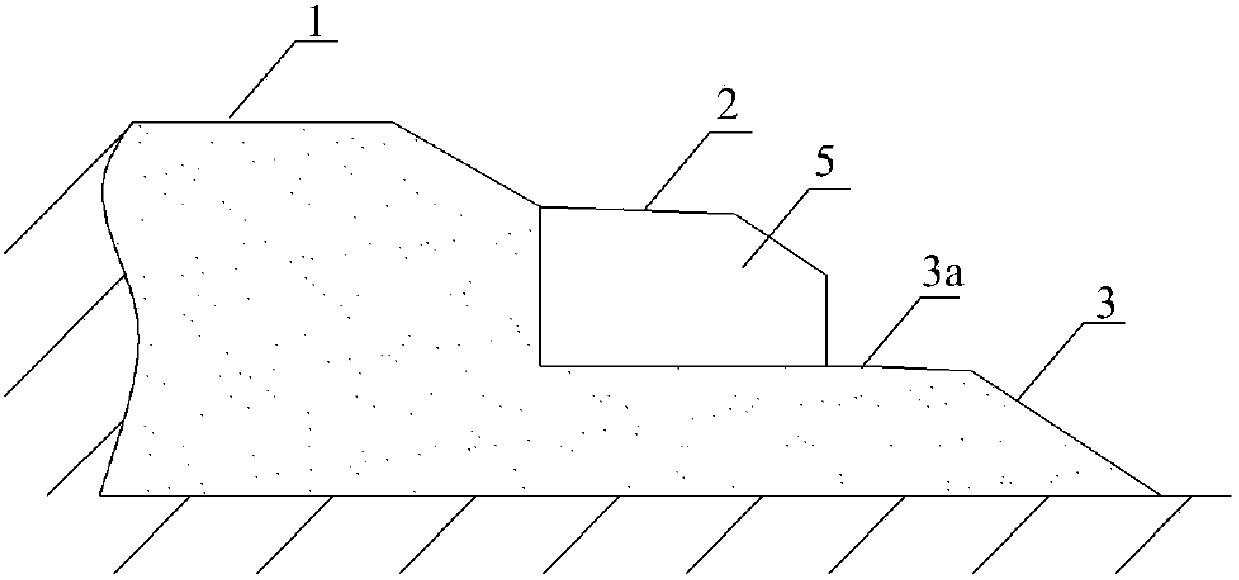

[0024] A. On the road shoulder 2 of the railway roadbed and the roadbed slope 3 outside the road shoulder 2, excavate at equal intervals longitudinally along the line for horizontally placing units The transverse groove 5 of the transverse rib 4a of shaped member; The inner end of transverse groove 5 is positioned at the intersection of road shoulder 2 and ballast bed 1; The length of described transverse rib 4a equals the width of new road shoulder 2 ' after widening;

[0025] B. On the subgrade slope 3, cut the slope longitudinally along the line to form a horizontal unit for placing The slope platform 3a of the longitudinal panel 4b of the shaped member;

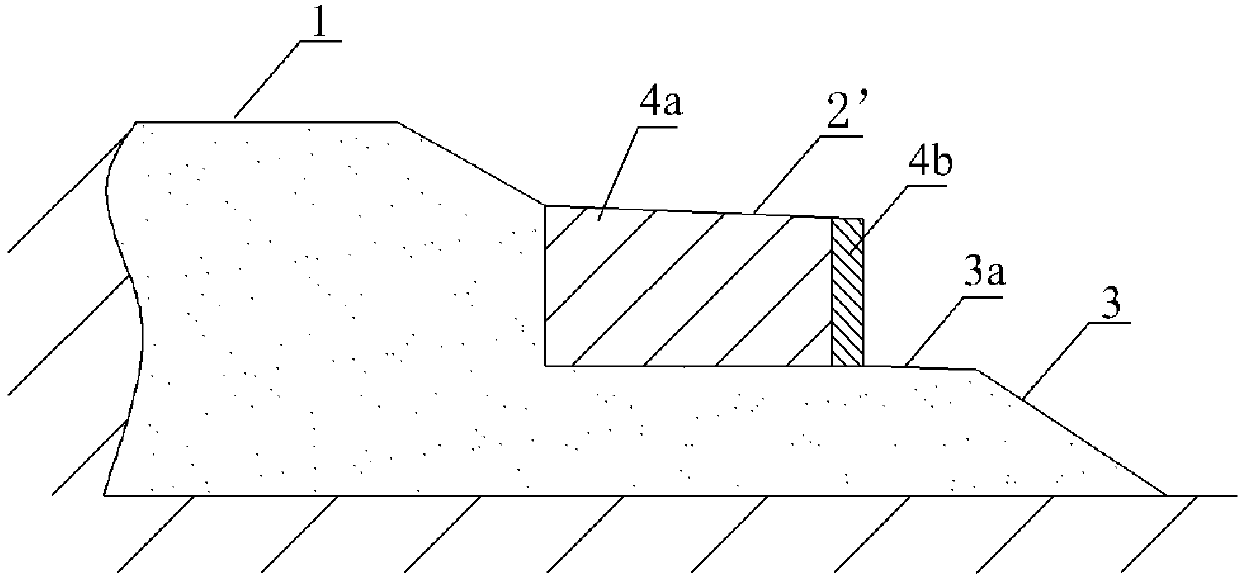

[0026] C. Put the unit The transverse rib 4a of the shaped member is placed in the transverse groove 5, and its longitudinal panel 4b is placed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com