Precast assembled pipeline combined shaft

A prefabricated assembly and pipeline technology, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve the problems of easy water seepage, long construction period, etc., achieve good sealing effect, ensure the quality of finished products, and improve the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

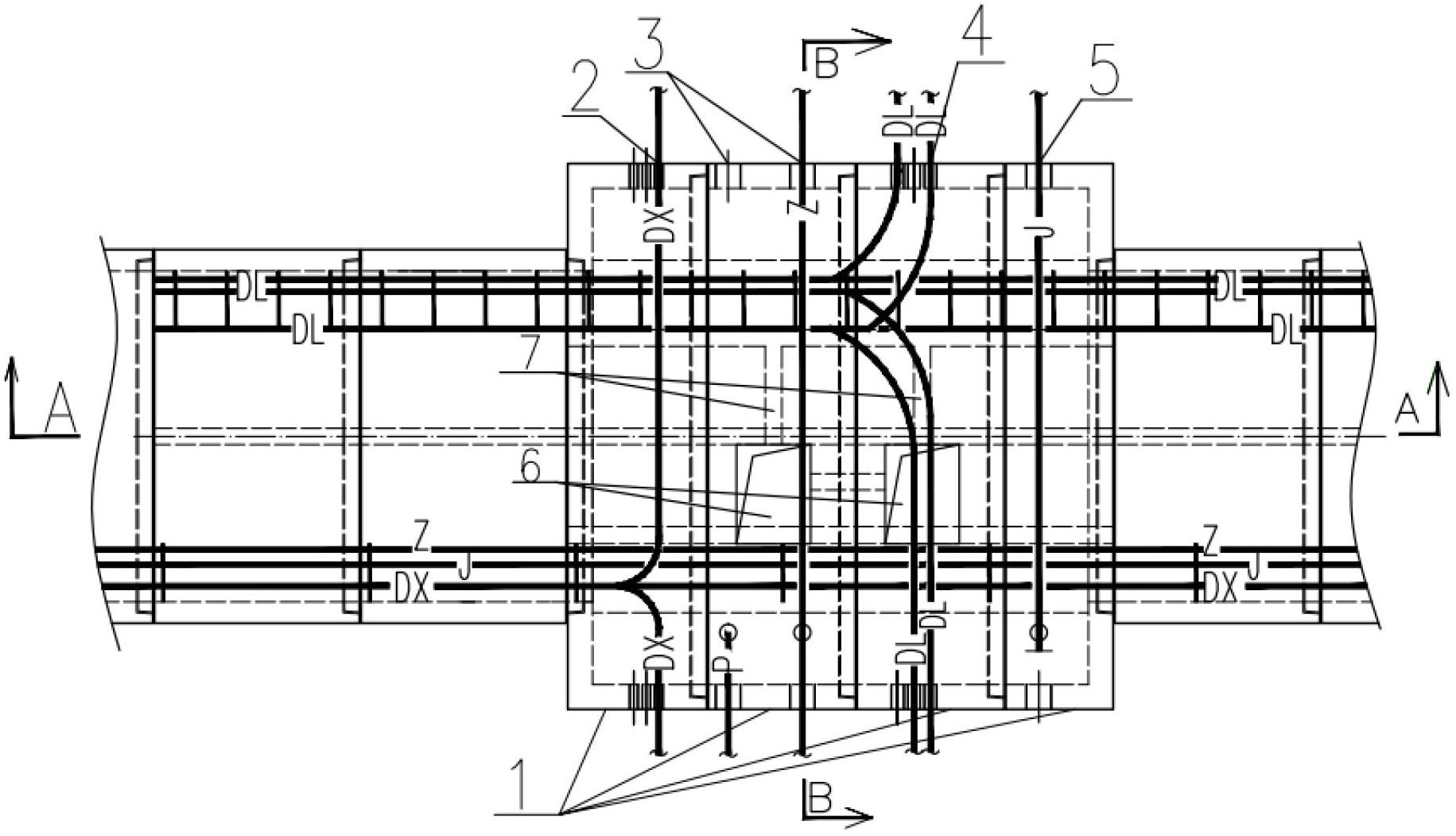

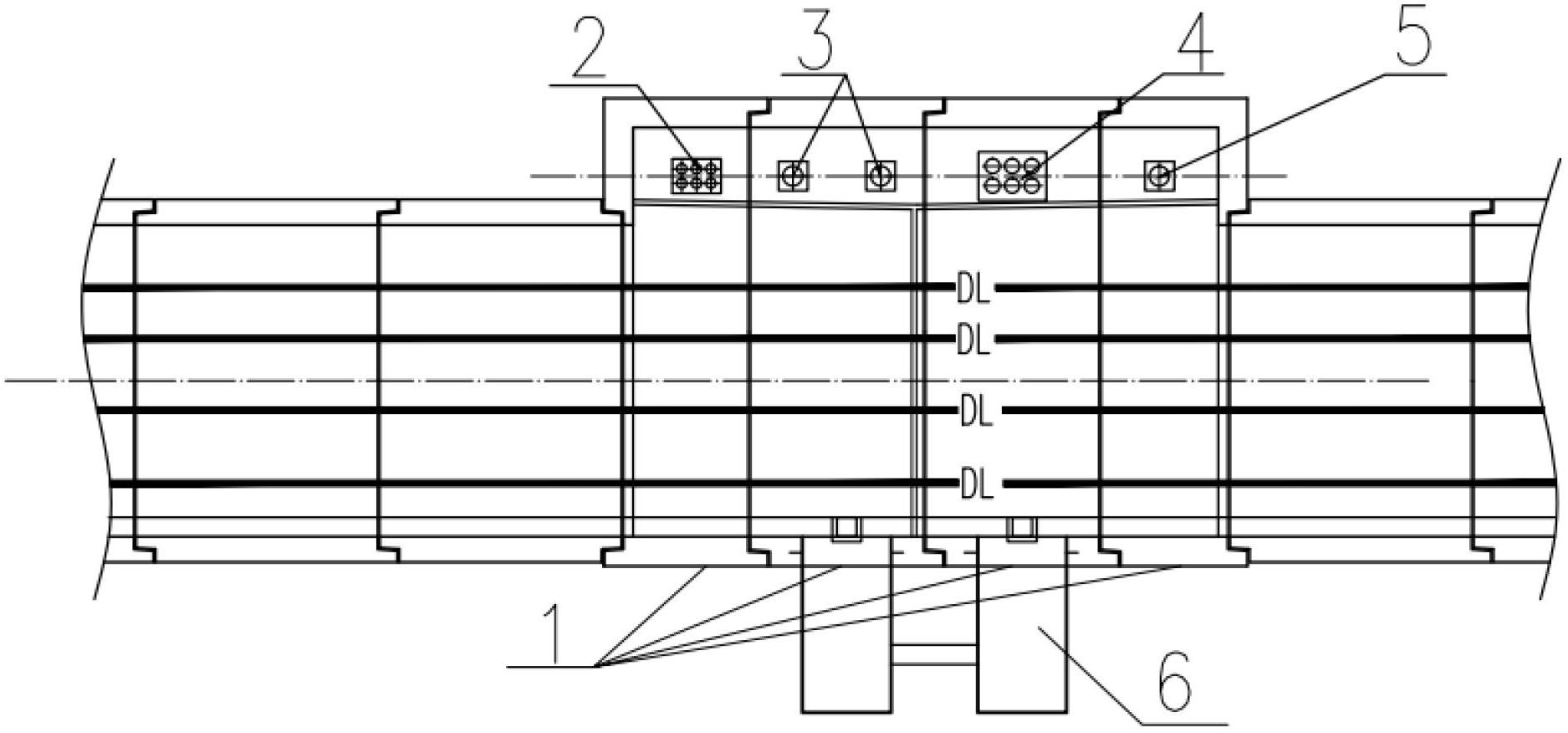

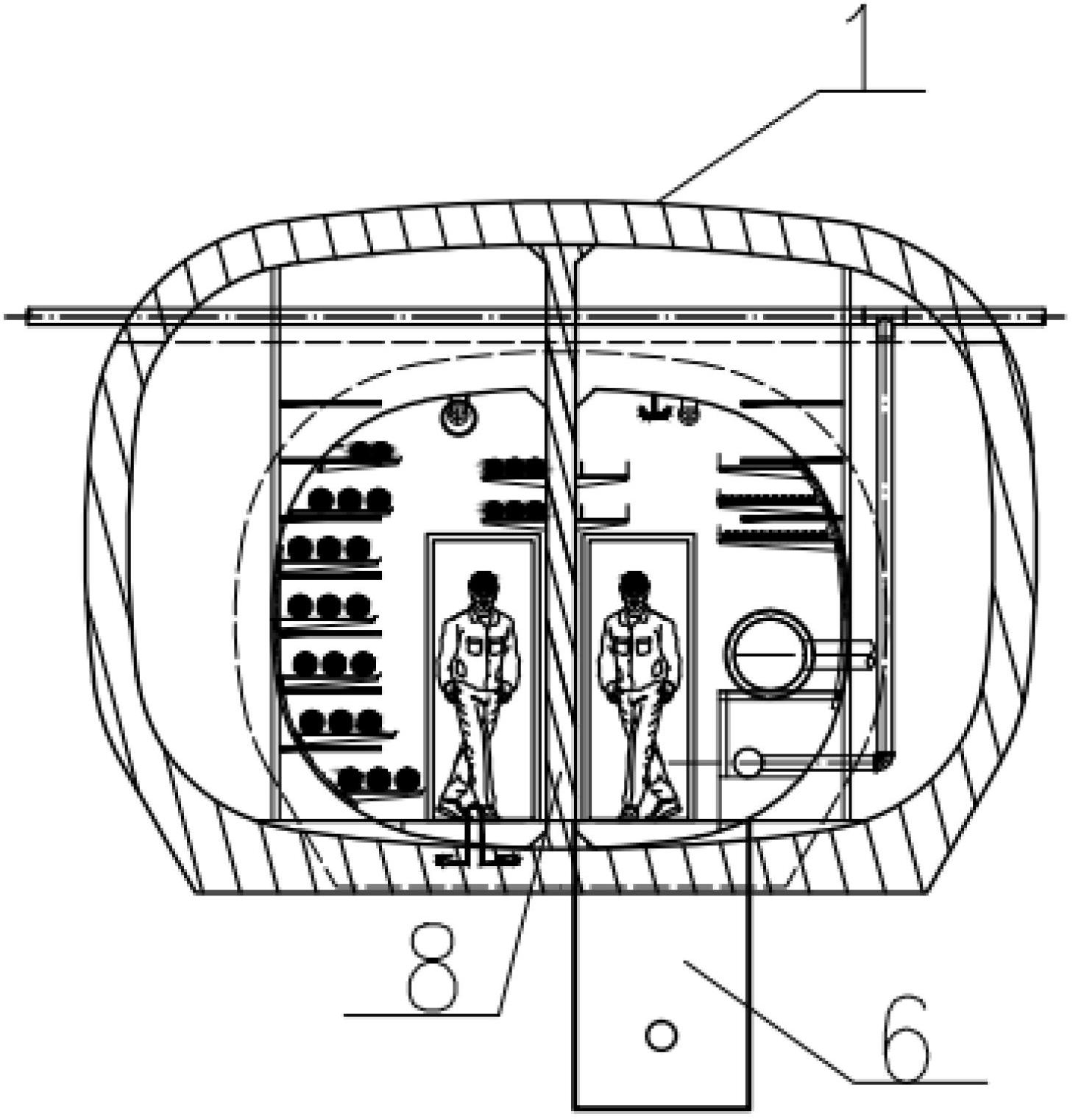

[0023] Such as Figure 1-Figure 3 As shown, a specific embodiment of the prefabricated assembled pipeline combination well of the present invention includes 4 prefabricated pipe joints 1 connected by flexible sockets, and the joints of two adjacent prefabricated pipe joints 1 are put into the joints used as seals. Double O-shaped rubber ring for flexible socket connection. Each prefabricated pipe section 1 is sequentially spliced to form a pipeline combined well structure. The cross section of the prefabricated pipe section 1 in the present invention is oval.

[0024] Such as figure 2 As shown, the side wall of the prefabricated pipe section 1 is provided with reserved holes for access, specifically, the pre-buried 6-hole DN150 information hole 2, the pre-buried DN100A rigid waterproof casing 3, the pre-buried 6-hole DN150 power hole 4, Pre-buried DN200A type rigid waterproof casing 5 for the entry and exit of pipes and cables.

[0025] The bottom of the prefabricated p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com