Secondary sedimentation tank dross filtration device

A secondary settling tank and scum technology, applied in the direction of the feeding/discharging device of the settling tank, settling tank, etc., can solve the problems of affecting the quality of the effluent water, failing to meet the national discharge standards, etc., and achieve the effect of avoiding the flow into the water tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

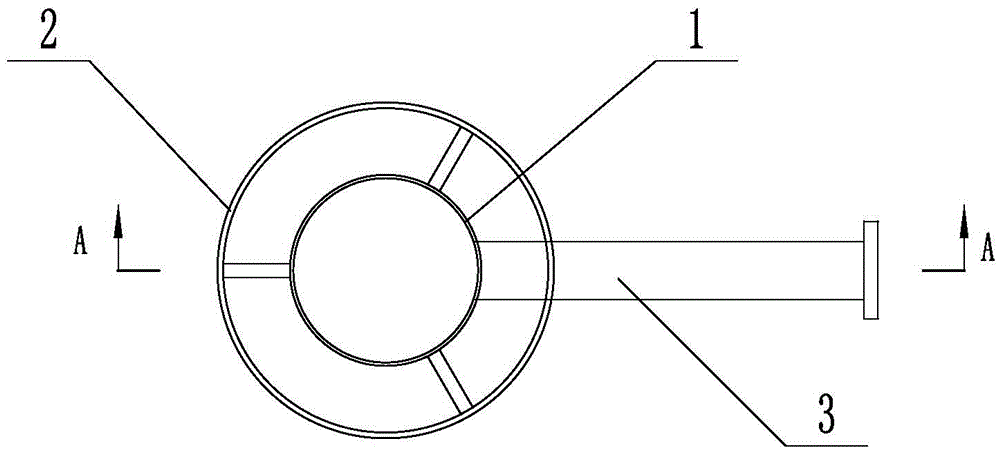

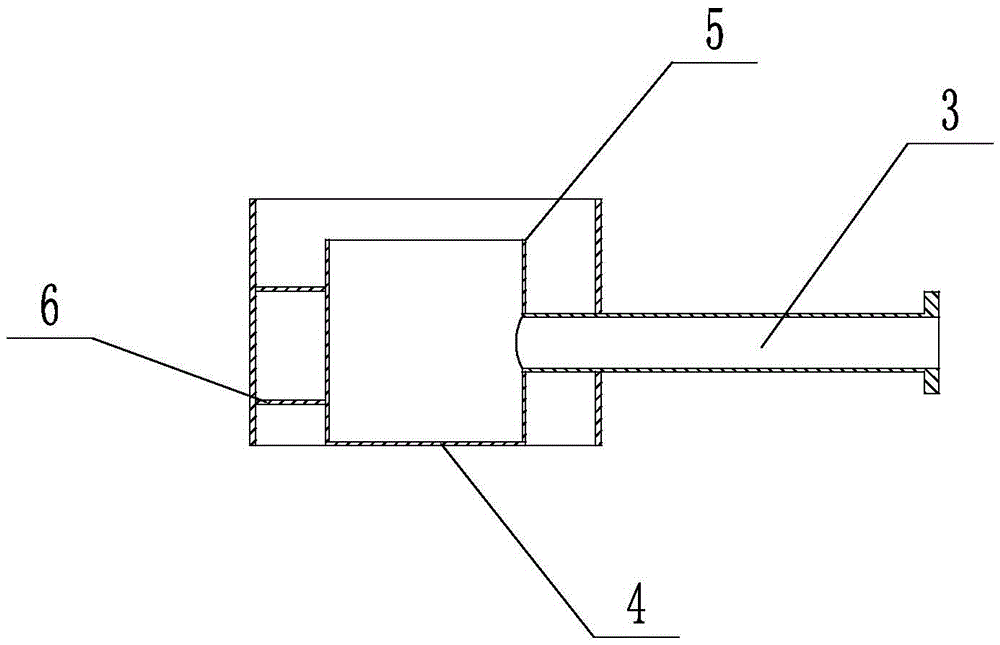

[0017] Such as Figure 1-2 As shown, the present invention includes a water tank 1, a baffle plate 2 and a drain pipe 3, the water tank 1 is welded by a bottom plate 4 and a side plate 5, the outside of the water tank 1 is connected with a baffle plate 2 through a cross brace 6, and the The water tank 1 is arranged inside the baffle plate 2, the upper edge of the side plate 5 is located between the upper edge and the lower edge of the baffle plate 2, and the water tank 1 and the drain pipe 3 are connected and welded together.

[0018] Working principle of the present invention: when the water level in the secondary settling tank 7 rises to the upper edge of the side plate 5 of the water tank 1, since the upper edge of the side plate 5 is located between the upper edge and the lower edge of the baffle plate 2, the upper edge of the water level The scum is blocked on the outside of the baffle plate 2, and the water level below the scum flows into the water tank 1 from the gap be...

Embodiment 2

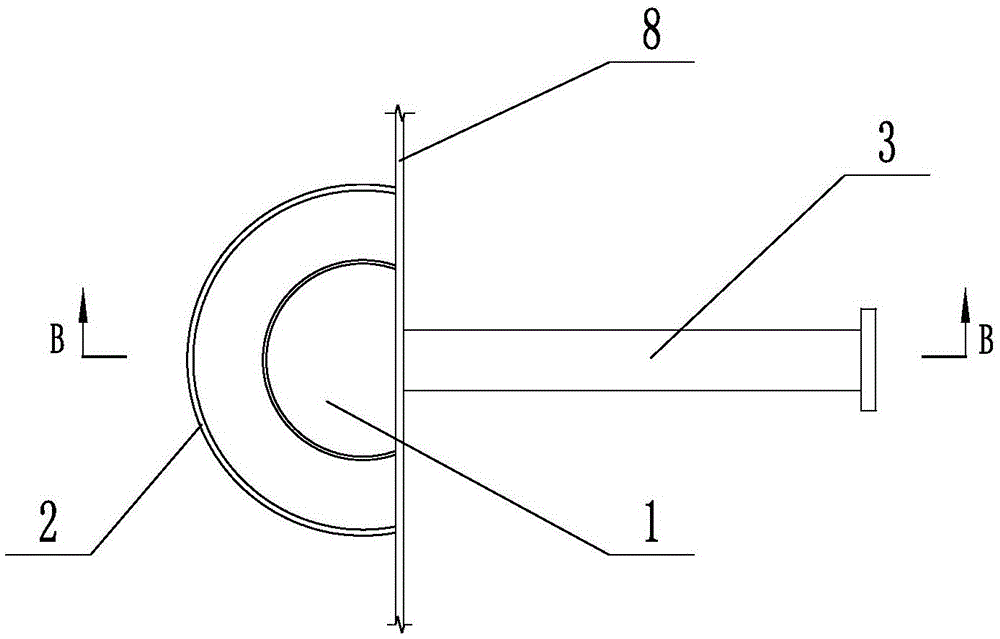

[0020] Such as Figure 3-5 As shown, the present invention includes a water tank 1, a baffle plate 2 and a drain pipe 3, the water tank 1 is welded by a bottom plate 4 and a side plate 5, and the water tank 1 is welded to a pool wall 8 along the bottom plate 4 and the side plate 5, A baffle plate 2 is provided outside the water tank 1 . Both ends of the baffle plate 2 are disconnected and welded to the pool wall 8 . The drain pipe 3 is welded on the pool wall 8 and communicated with the water tank 1 .

[0021] Working principle is the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com