Composite waterproof board and production technology thereof

A production process and technology of waterproof board, applied in the direction of synthetic resin layered products, layered products, lamination, etc., can solve the problems of serious water leakage, water channeling, etc., to save energy costs, prevent water channeling, and facilitate replacement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] combine Figure 7 , Figure 8 . Figure 7 It is a sectional view of the composite waterproof board of the present invention; Figure 8 It is a plan view of the composite waterproof board with block bonding parts of the present invention.

[0043] as the picture shows. The composite waterproof board includes a waterproof board and a geotextile, the geotextile is located on one surface of the waterproof board, the geotextile and the waterproof board have evenly distributed and discontinuous bonding parts, and the bonding parts have evenly arranged suspension fixtures. On the other surface of the waterproof board, there is a self-adhesive layer made of rubber-modified asphalt coating compound, and the surface of the self-adhesive layer is compounded with an isolation film.

[0044] In this example, the hanging and fixing parts are made of cotton fiber braid, the width is 15-25mm, the length is 200-300mm, the tensile strength is ≥300N / 10mm, and the number of fixing part...

Embodiment 2

[0050] combine Figure 7 , Figure 9 . Figure 7 It is a sectional view of the composite waterproof board of the present invention; Figure 9 It is a plan view of the composite waterproof board with strip bonding part of the present invention.

[0051] as the picture shows. The difference between this example and Example 1 lies in the shape of the adhesive part. In this example, the adhesive part is an adhesive strip arranged in parallel along the length direction of the waterproof board, that is, a longitudinal adhesive strip, and the hanging fixing parts are evenly arranged on the strip-shaped adhesive part. , due to the hydrophobic and drainage channels reserved in the strip-shaped bonding part, the further drainage requirements are met. Other structures are with embodiment 1.

[0052] Similarly, the strip-shaped adhesive part can also be arranged vertically along the length direction of the waterproof board, that is, the transverse adhesive strip, and other structures...

Embodiment 3

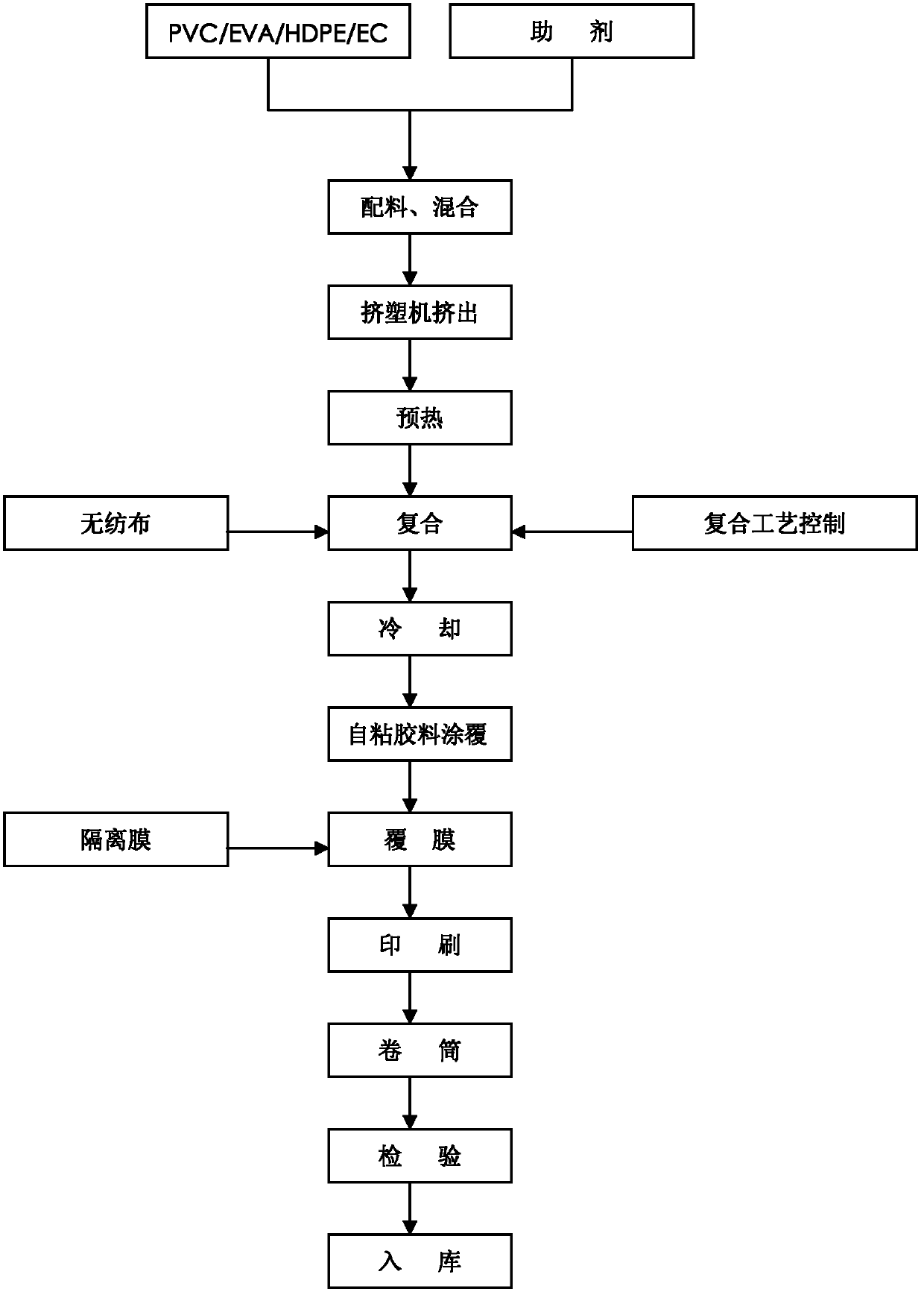

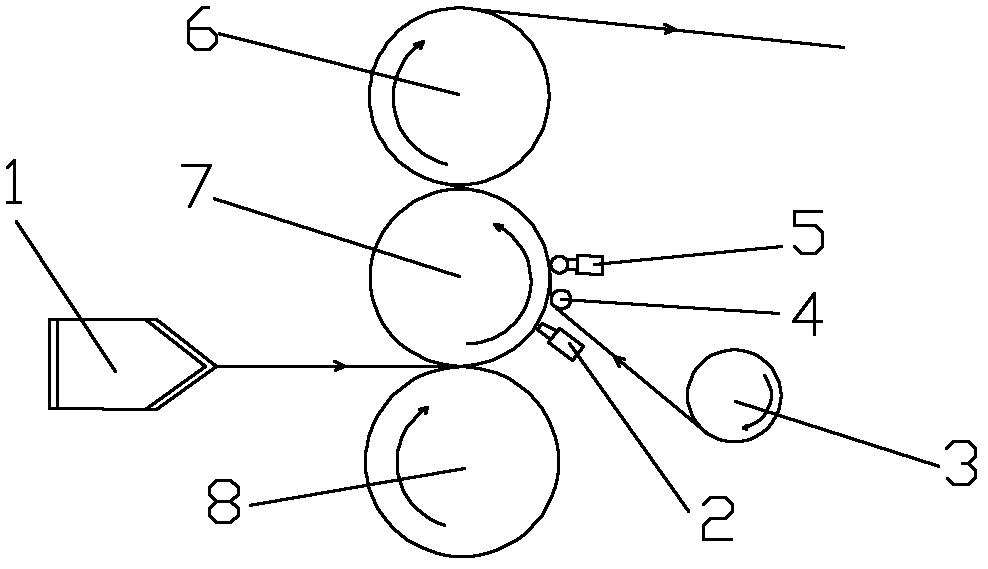

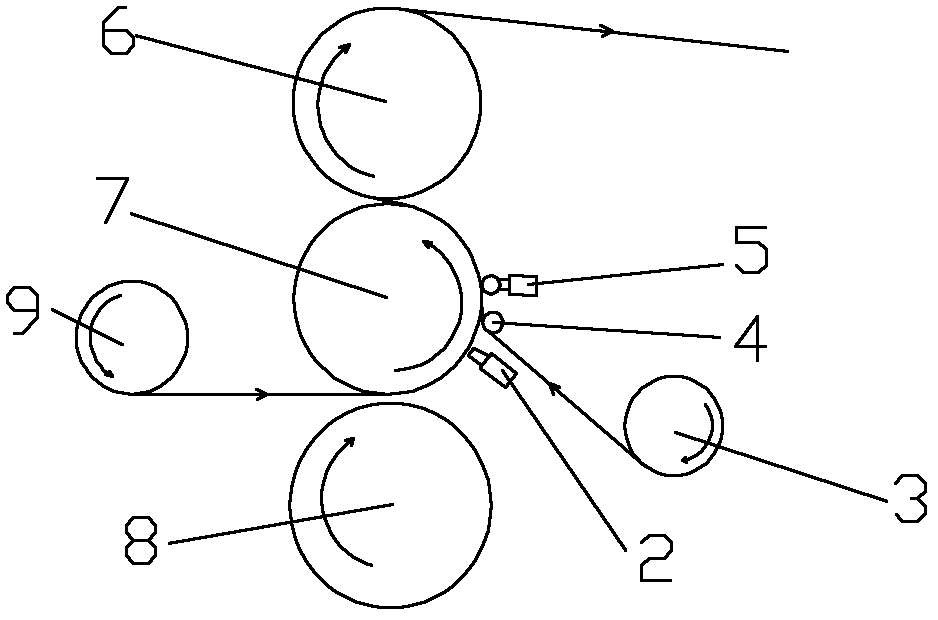

[0056] combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 .

[0057] as the picture shows.

[0058] The production process flow of the present invention is divided into four stages: the first stage is raw material preparation and extrusion molding, the second stage is preheating and bonding, the third stage is self-adhesive rubber coating and film covering, and the fourth stage is Finished products for rolls.

[0059] specifically is:

[0060] 1) The waterproof sheet is extruded from the main raw material through the extruder, and then extruded by the pressure roller of the extrusion device to form the main sheet of the waterproof sheet, and then sent to the cooling roller through the conveying supporting device.

[0061] 2) Preheating the fixed-point position set by the main body sheet through the hot air preheating device 2; causing one side of the main body sheet to be heated and slightly melted. The melting width of the block bonding pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com