750 kV framework structure suitable for large-gradient site

A site and slope technology, which is applied in the field of 750kV frame structure and civil structure professional frame, can solve the problems of 750kV frame structure foundation design difficulties, inconvenient construction and installation, and different frame column heights, so as to reduce the amount of excavation and filling on the site and meet the Site drainage requirements, the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

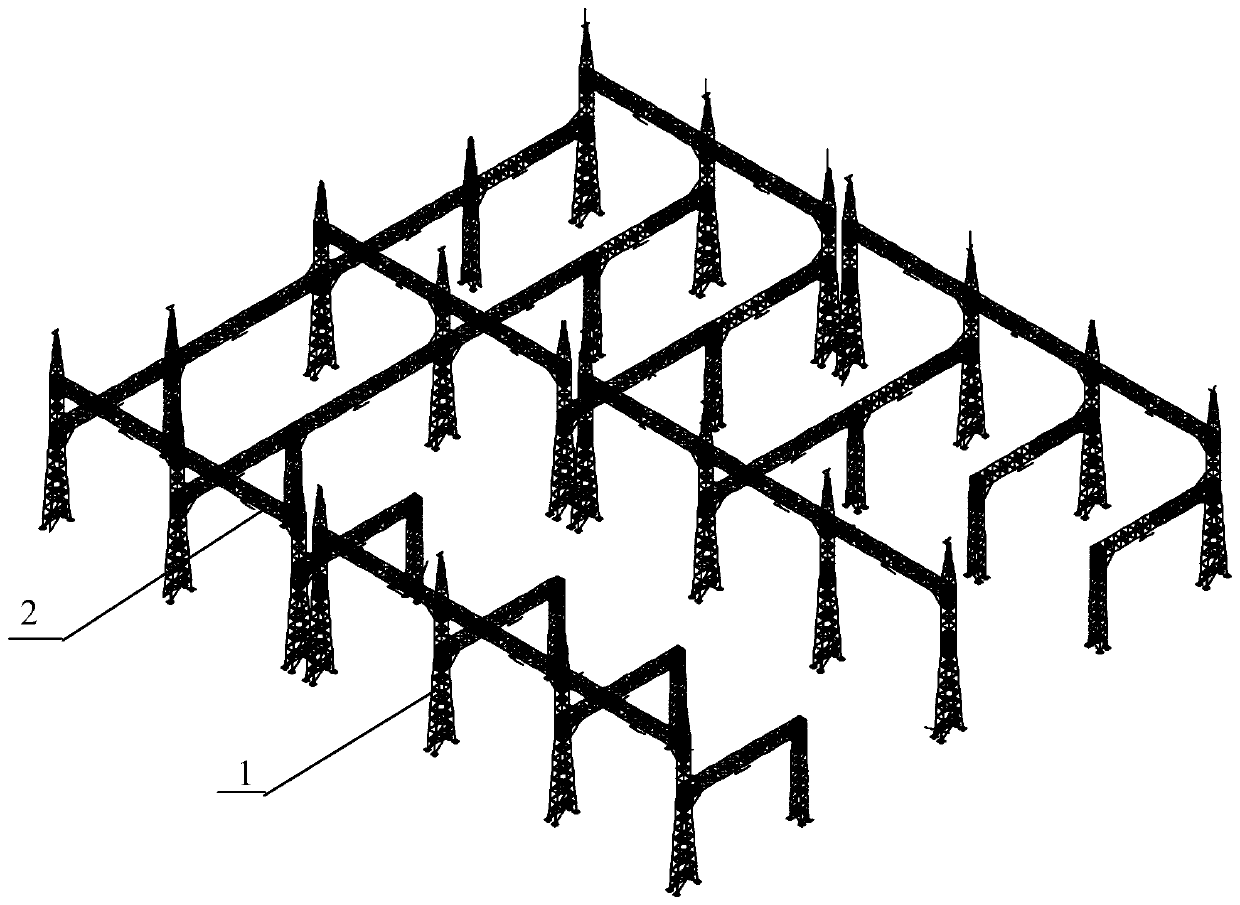

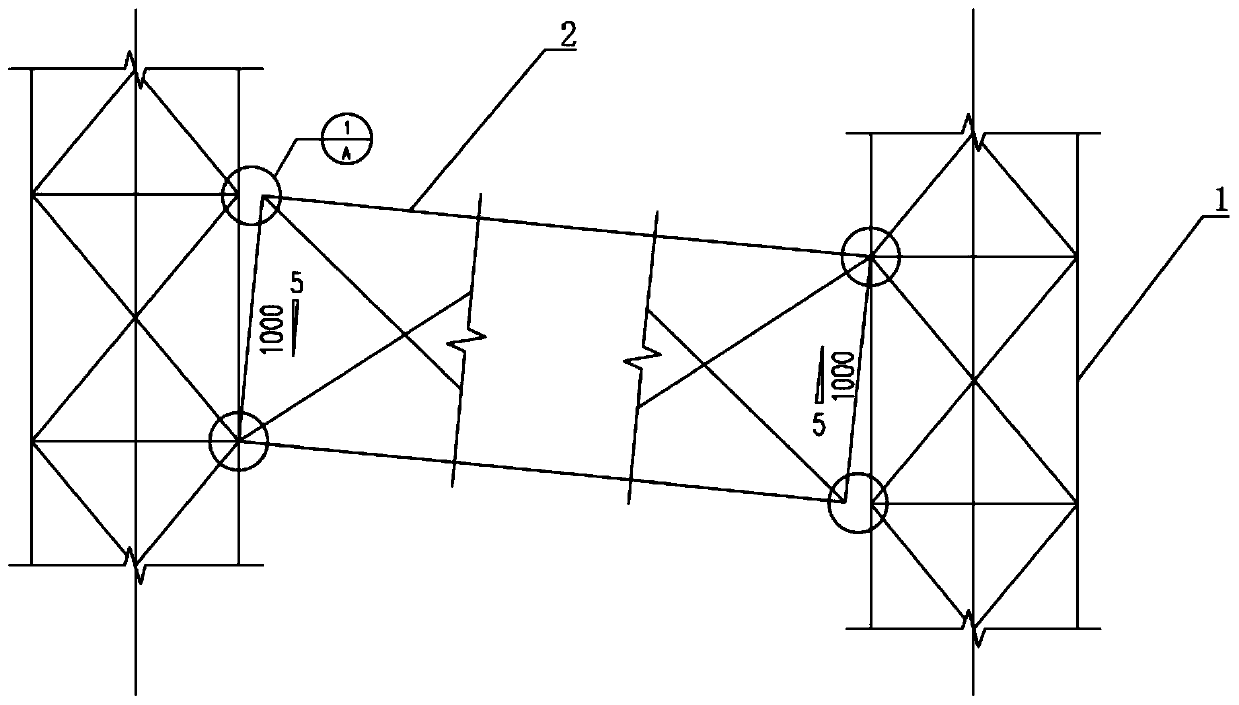

[0032] Such as figure 1 As shown, in this embodiment, a 750kV frame structure suitable for sites with relatively large slopes is specifically disclosed, including several frame columns 1. The bottom end of each frame column 1 is buried in the site at the same depth, and the embedment depth of each frame column 1 relative to the surface of the site is the same, and the site is simulated as a standard slope, then each frame column The vertical spacing between the top of 1 and the surface of the site is equal, which can also be understood as the same vertex of each frame column 1 is connected to form a "face", and the "face" should be parallel to the slope of the site. Preferably, the frame The column 1 includes several A-shaped steel pipe columns, and the use of the A-shaped steel pipe columns to form the frame column 1 can ensure that the frame column 1 has good stability and bearing capacity.

[0033] Such as figure 2 As shown, at least one frame beam 2 is arranged between ...

Embodiment 2

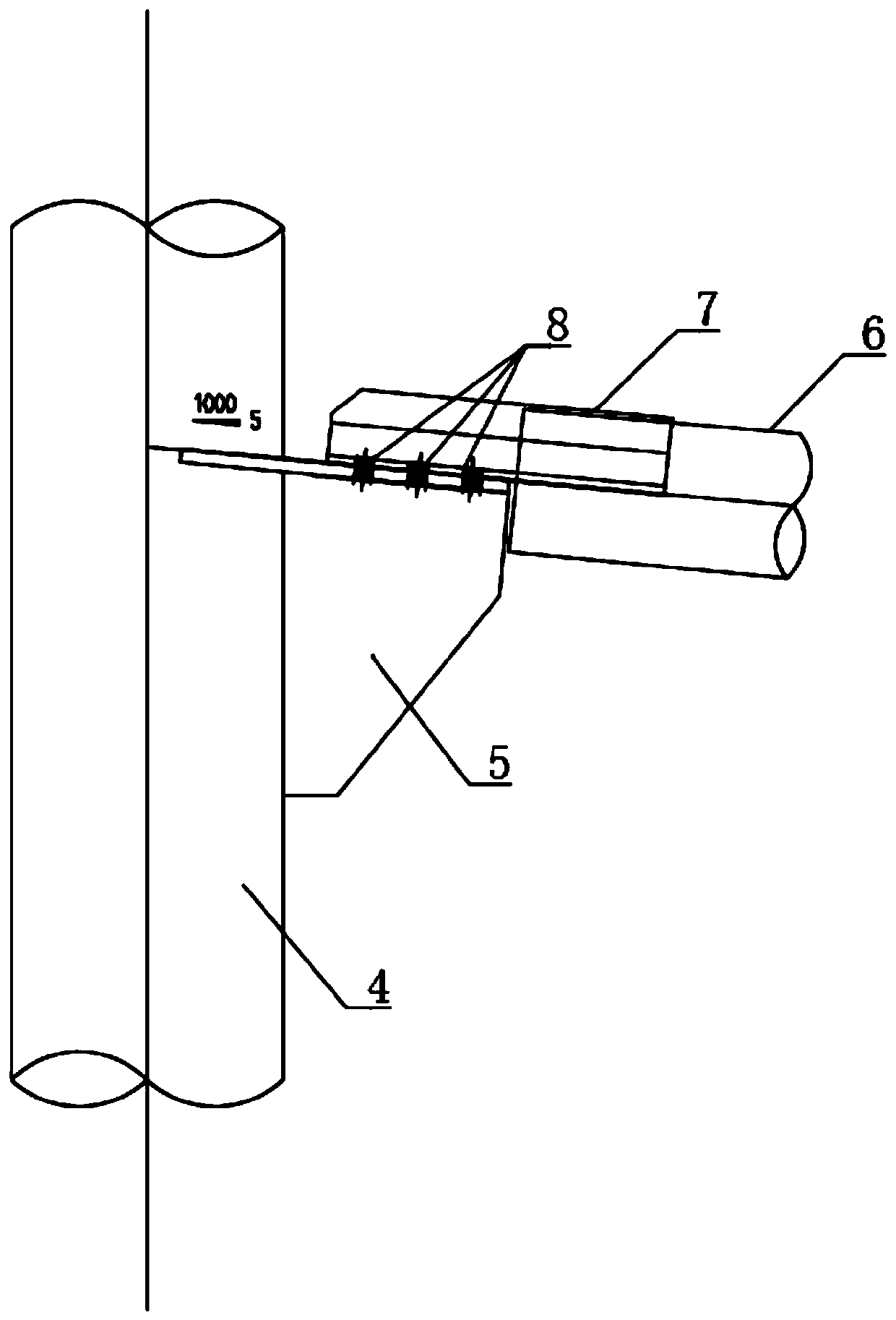

[0039] In Example 1, in order to realize the pre-positioning of the beam inserting plate 7, the method of increasing the frictional force is adopted. This method has low reliability, and in the assembly process, the assembly is difficult and labor-intensive. The concept of convenient and quick installation in the process, therefore, on the basis of Embodiment 1, the following structural design is adopted to realize convenient and quick pre-positioning during the installation process of the beam inserting plate 7, such as Figure 8 , Figure 9 As shown, as follows:

[0040] It also includes a rotary sleeve 13 that is placed on the beam chord 6, and a plurality of arc clips 15 are arranged on the circumferential direction of the rotary sleeve 13, and each arc clip 15 is formed with the beam chord 6. Concentric arrangement and the same side of each arc clamping plate 15 are all provided with clamping head, and each described arc clamping plate 15 is respectively positioned betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com