Combined prefabricated retaining wall square pile foundation pit supporting structure and construction method thereof

A technology of supporting structure and construction method, which is applied in basic structure engineering, excavation, sheet pile wall, etc., can solve problems such as waste of resources, waste of land, noise pollution, etc., to save project cost, expand use area, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] Such as Figure 1 to Figure 8 As shown, what the present invention discloses is a kind of construction method of combined prefabricated retaining wall square pile foundation pit support structure, comprising:

[0078] Step S1, leveling the construction site of the foundation pit, and removing the pipelines that affect the construction of the foundation pit;

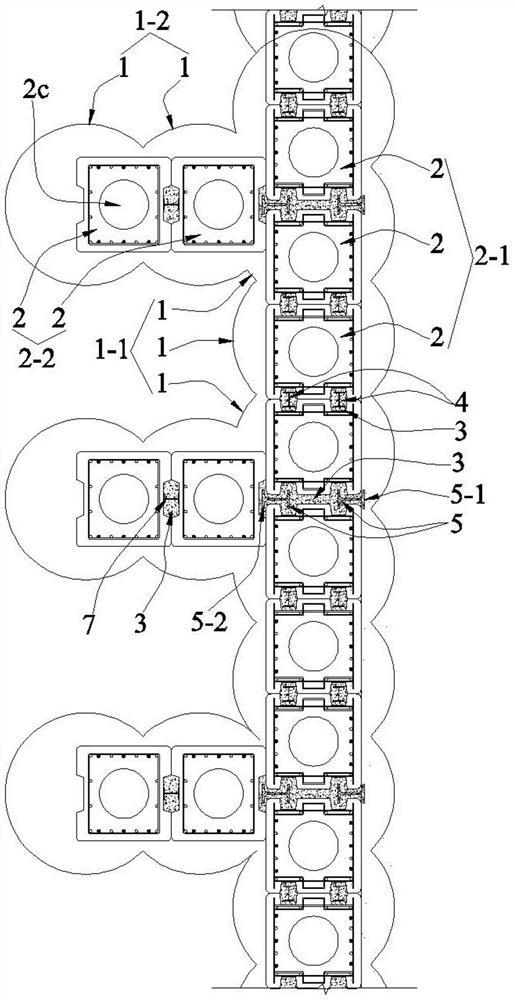

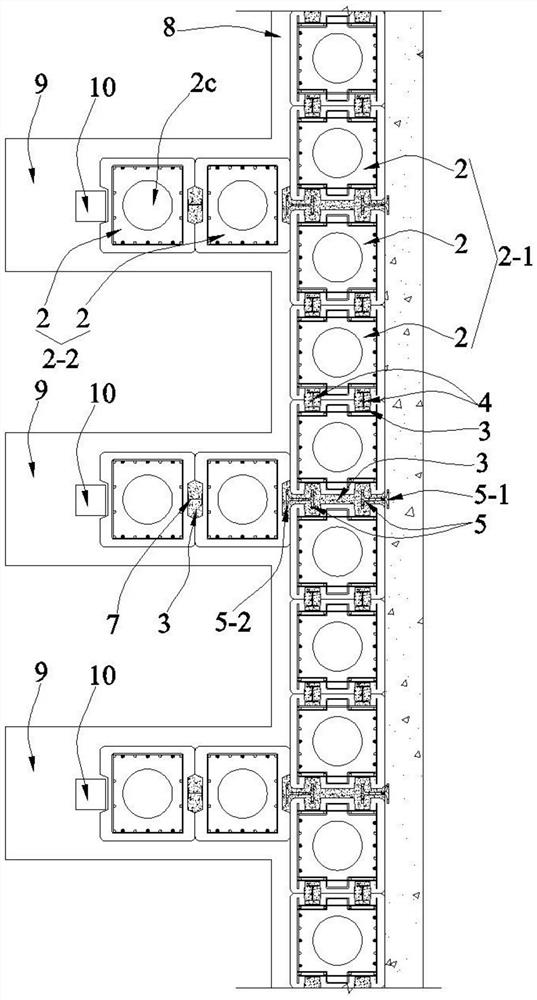

[0079] Step S2, construct multiple groups of mixing piles 1 on the construction site to connect and form a ring belt 1-1 of mixing piles around the foundation pit to be constructed; and insert prefabricated piles 2 vertically into the mixing piles 1 to form A prefabricated pile ring 2-1 extending along the stirring pile ring 1-1;

[0080] Among them, the corresponding prefabricated pile 2 should be inserted before the initial setting of the gel formed by mixing the cement slurry and soil in the hole in the mixing pile 1, so as to prevent the prefabricated pile 2 from being difficult to insert or the fixing of the ...

Embodiment approach

[0095] The connection modes between the prefabricated pile ring belt 2-1, the prefabricated pile auxiliary belt 2-2, the micro-expansion concrete 3, the connecting steel member 4, the external steel member 5 and the auxiliary belt connecting steel member 7 are preferably the following three One of the options:

[0096] Option 1, see Figure 2 to Figure 6 , the prefabricated pile 2 has a rectangular cross-section and is divided into a double-groove prefabricated pile 2A and a single-groove prefabricated pile 2B. Groove 2A1, the single-groove prefabricated pile 2B is symmetrically provided with a single row of grooves 2B1 extending along its axial direction on its opposite sides;

[0097] In addition, the double-slot prefabricated pile 2A is used to form the precast pile ring belt 2-1, and the single-slot prefabricated pile 2B is used to form the prefabricated pile auxiliary belt 2-2; The double-row grooves 2A1 adjacent to the two double-groove prefabricated piles 2A are conne...

Embodiment 3

[0106] On the basis of the above-mentioned embodiment 1 or embodiment 2, this embodiment 3 also adopts the following preferred implementation modes:

[0107] The construction method also includes after the step S3 and before the step S4:

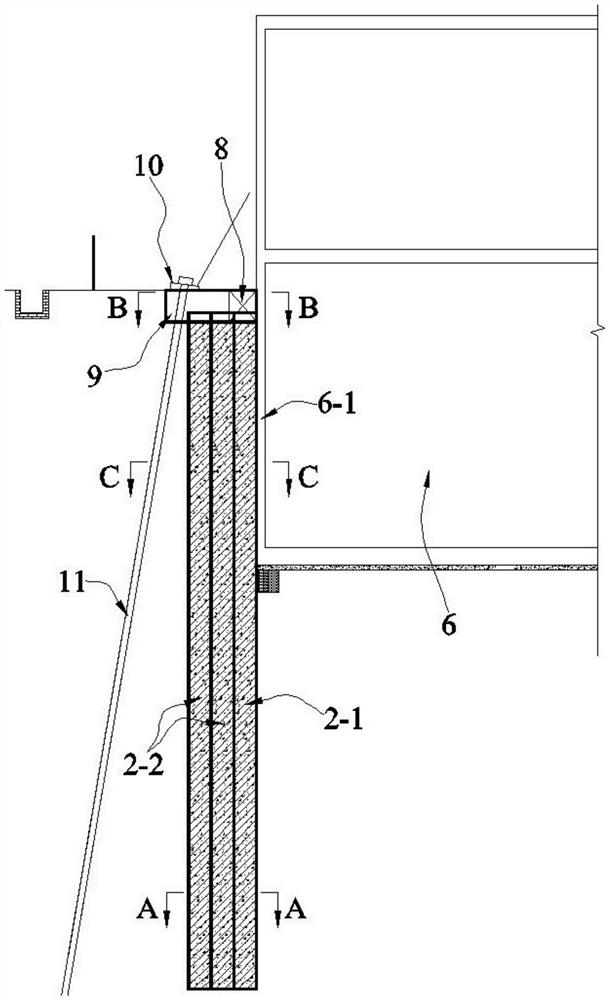

[0108] Step S3-1, grading and excavating the soil above the underground retaining wall and the lateral support wall, and constructing a crown beam 8 on the top of the underground retaining wall, and constructing a connection at the top of the lateral support wall Beam 9, wherein, the crown beam 8 and the tie beam 9 are reinforced concrete beams, and the steel bars of the crown beam 8 and the tie beam 9 are overlapped with the steel bars of the corresponding prefabricated pile 2;

[0109] Step S3-2. After the crown beam 8 and the connecting beam 9 reach 70% of the design strength, place a wedge-shaped anchor backing plate 10 on the top surface of the connecting beam 9. The wedge-shaped anchor backing plate 10 has an inwardly inclined and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com