Three-dimensional cultivation device with cultivation tray automatic feeding and discharging function

A technology of three-dimensional cultivation and cultivation tray, which is applied in container cultivation, storage device, transportation and packaging, etc., can solve the problems of low space utilization rate, high labor input, high labor intensity, etc. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

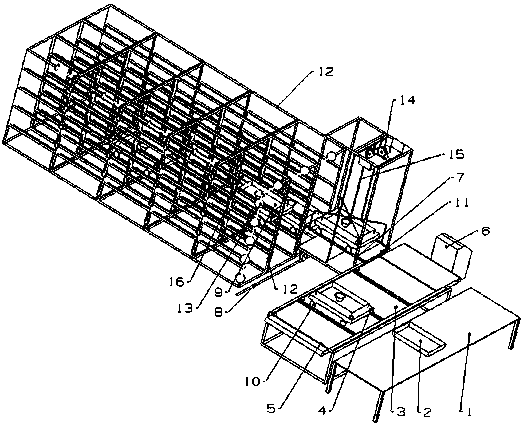

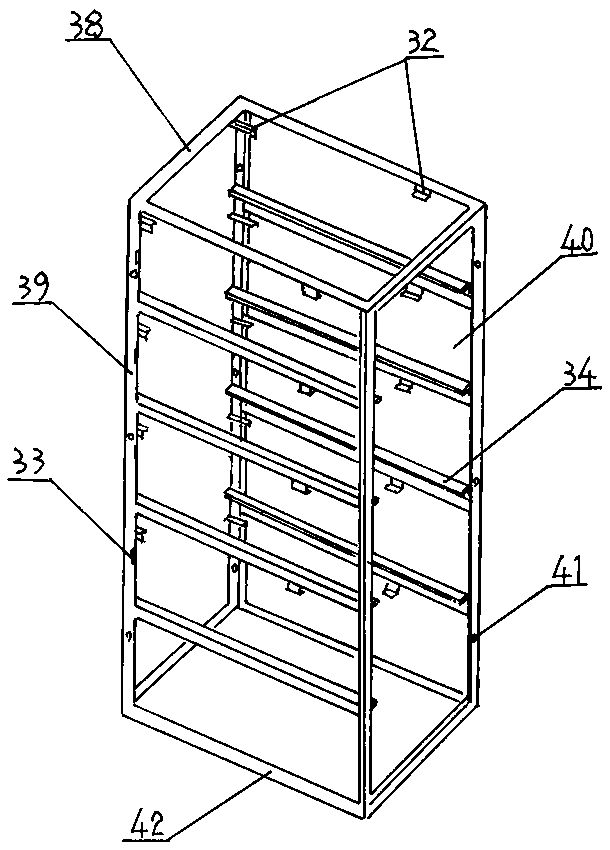

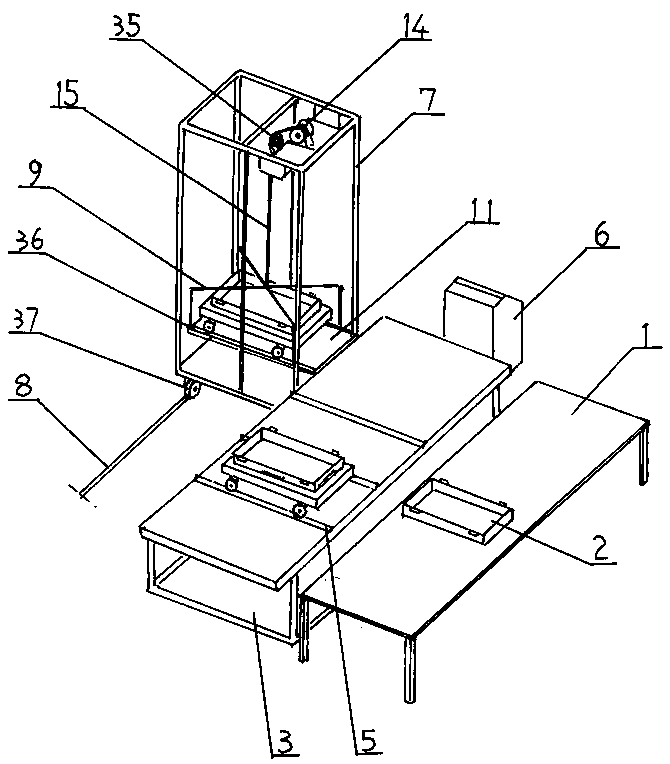

[0023] Such as Figure 1 to Figure 5 As shown, a cultivation tray automatic entry and exit type three-dimensional cultivation device is composed of a cultivation tray 2, a console 6 and an operation console 1. The console is equipped with reading data from various sensors and controlling the operation of the transport vehicle, the operation of the elevator car, A computer or program control module that sends and receives signals, records the position of the cultivation unit, the growth of the crops on the cultivation rack array, and controls the distribution of the cultivation trays in the cultivation rack array according to the plan. Control buttons and a display screen are arranged on the console. The lift locomotive runs on the locomotive track 8. One side perpendicular to the locomotive track is provided with a cultivation rack array 12 composed of several cultivation racks connected in parallel and in series, and the other side perpendicular to the locomotive track is su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com