Continuous rotating and vibrating cutting equipment realizing pregrooving and used for hard rock ore body and construction process of equipment

A technology of pre-cutting grooves and ore bodies, which is applied in cutting machinery, driving devices, ground mining, etc., and can solve the problems of a large amount of mineral dust, respirable mineral dust concentration, easy wear of picks or knives, and high mining costs. , to achieve the effect of easy precise regulation, high production efficiency and large production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings.

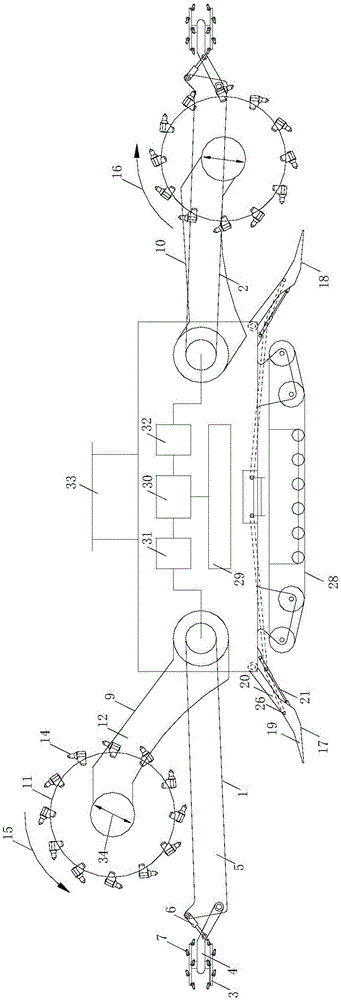

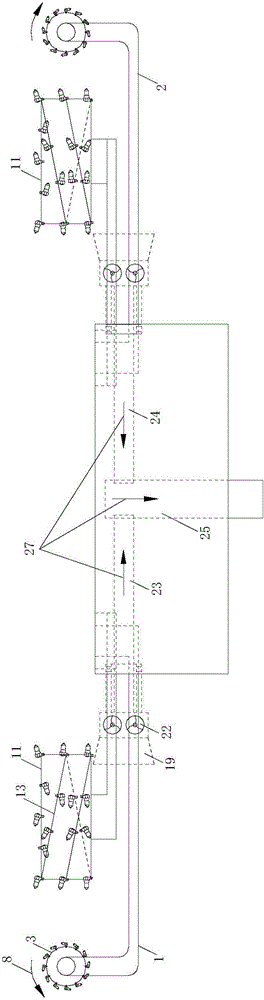

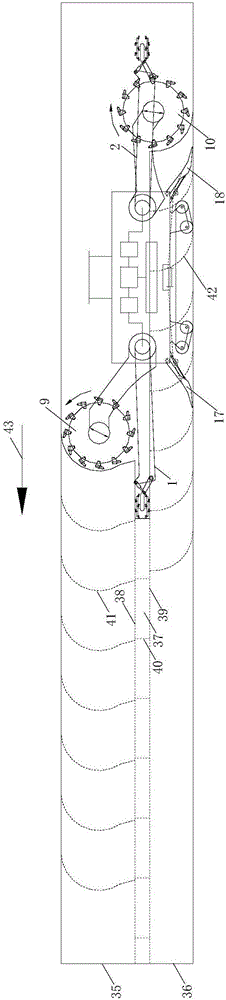

[0050] see figure 1 and figure 2 , a pre-grooving hard rock ore body rotary vibration continuous cutting equipment, which is composed of two ore body grooving mechanisms installed in the front and rear of the equipment and extending out to form horizontal grooving in the ore body to be cut in advance, arranged Two ore body cutting mechanisms, one up and one down at the front and back of the equipment, the ore shoveling mechanism installed at the bottom of the equipment, the traveling mechanism 28, the hydraulic pump station 29, the hydraulic distribution and control system 30, and the hydraulic distribution and control system 30 It is composed of the front hydraulic exciter 31 and the rear hydraulic exciter 32 between the ore body cutting mechanism, and the operating room 33 which is set on the top of the equipment and can observe the grooving, cutting, shipping and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com