Special portal-type bolster frame assembly manipulator for truck bogie production line

A bogie and manipulator technology, used in manipulators, program-controlled manipulators, metal processing, etc., can solve the problems of difficult assembly process, potential safety hazards, and difficulty in ensuring assembly quality, and achieve the effect of high assembly quality and elimination of potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

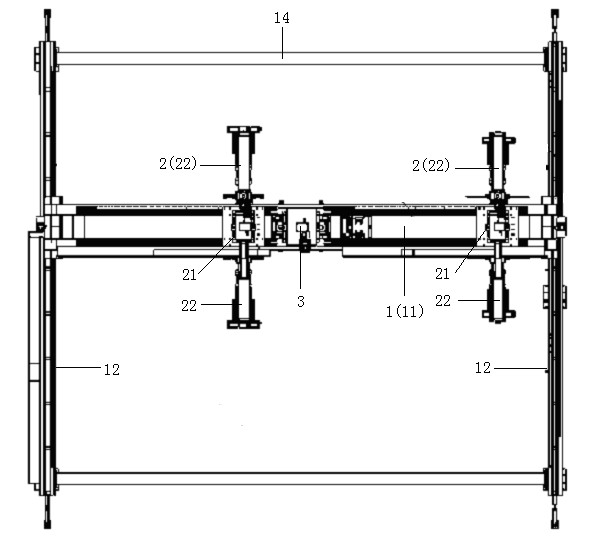

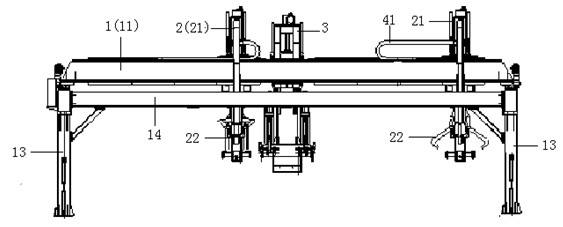

[0023] Such as figure 1 , 2 as shown,

[0024] The present invention is made up of frame 1, and side frame manipulator 2 installed on the frame, bolster manipulator 3 and electric controller 4 (only shows dragging-electric connecting line 41 in the figure). The frame is mainly composed of cross beams 11, running beams 12, vertical supports 13, and support beams 14 connected to each other. The side frame manipulator 2 is composed of a vertical lifting unit 21 and two sets of side frame grabbing, clamping and turning units 22 .

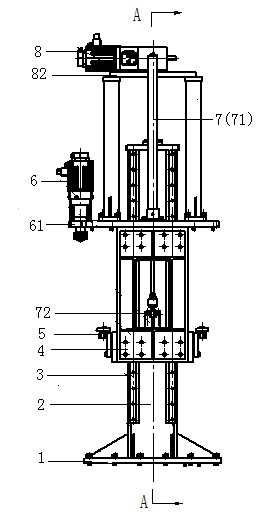

[0025] Such as image 3 , 4 as shown,

[0026] The side frame of the side frame manipulator operates laterally and vertically, and is mainly composed of a base 1, a column 2, a linear guide rail 3, a torsion-resistant connecting plate 4, a torsion-resistant bearing seat 5, a walking drive motor 6, a nitrogen balance device 7, and a lifting Motor 8 and lifting screw mandrel 81 form. Among them, the column is erected on the base, and the linear gui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com