Closed circulating and recycling method of waste lead-acid accumulator

A lead-acid battery and closed-cycle technology, which is applied in the direction of improving process efficiency, can solve problems such as pollution and low recycling efficiency, and achieve the effects of easy and simple operation, high degree of automation, and increased recycling value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

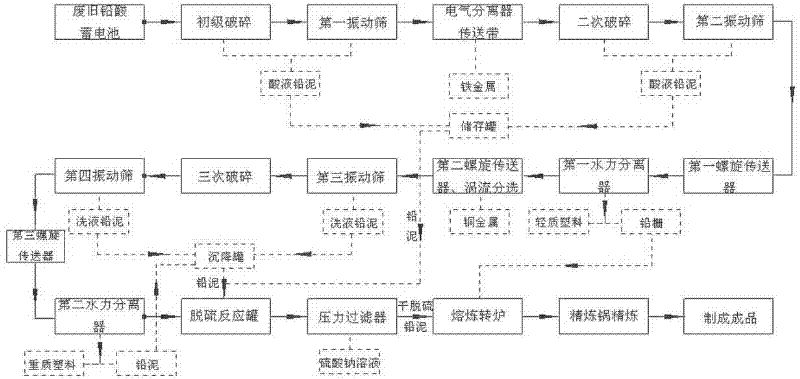

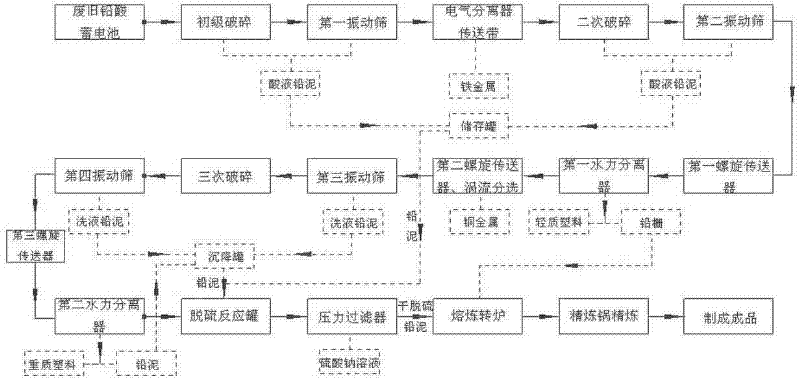

Image

Examples

Embodiment 1

[0045] A production method for closed-cycle recycling of waste lead-acid batteries, comprising the steps of:

[0046] (1) Primary crushing: waste lead-acid batteries are picked up by the claws and sent to the upper hopper, and then sent to the primary crushing hammer through the feeding conveyor for primary crushing, so that the size of the crushed mixture is 75mm, and the primary crushed The mixed material falls on the first vibrating screen for cleaning and sorting, and the lead sludge and acid produced in the process are sent to the storage tank;

[0047] (2) Magnetic separation: transport the crushed mixture on the first vibrating screen to the conveyor belt equipped with an electromagnetic separator, which will separate the ferromagnetic metal in the mixture;

[0048] (3) Secondary crushing: The mixture separated by the electromagnetic separator is sent to the secondary crushing hammer for secondary crushing, so that the size of the crushed mixture is 27mm, and the second...

Embodiment 2

[0060] A production method for closed-cycle recycling of waste lead-acid batteries, comprising the steps of:

[0061] (1) Primary crushing: waste lead-acid batteries are sent to the hopper through the claws, and then sent to the primary crushing hammer through the feeding conveyor for primary crushing, so that the size of the crushed mixture is 70mm, and the primary crushed The mixed material falls on the first vibrating screen for cleaning and sorting, and the lead sludge and acid produced in the process are sent to the storage tank;

[0062] (2) Magnetic separation: transport the crushed mixture on the first vibrating screen to the conveyor belt equipped with an electromagnetic separator, which will separate the ferromagnetic metal in the mixture;

[0063] (3) Secondary crushing: The mixture separated by the electromagnetic separator is sent to the secondary crushing hammer for secondary crushing, so that the size of the crushed mixture is 30mm, and the secondary crushed mix...

Embodiment 3

[0074] A production method for closed-cycle recycling of waste lead-acid batteries, comprising the steps of:

[0075] (1) Primary crushing: waste lead-acid batteries are picked up by the claws and sent to the upper hopper, and then sent to the primary crushing hammer through the feeding conveyor for primary crushing, so that the size of the crushed mixture is 73mm, and the primary crushed The mixed material falls on the first vibrating screen for cleaning and sorting, and the lead sludge and acid produced in the process are sent to the storage tank;

[0076] (2) Magnetic separation: transport the crushed mixture on the first vibrating screen to the conveyor belt equipped with an electromagnetic separator, which will separate the ferromagnetic metal in the mixture;

[0077] (3) Secondary crushing: The mixture separated by the electromagnetic separator is sent to the secondary crushing hammer for secondary crushing, so that the size of the crushed mixture is 25mm, and the second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com