Sorting and stacking device for ceramic bricks

A ceramic tile stacking technology, applied in the stacking, transportation, and packaging of objects, can solve the problems of low production efficiency, high labor intensity, and high labor cost, and achieve reduced management costs, high automation, and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

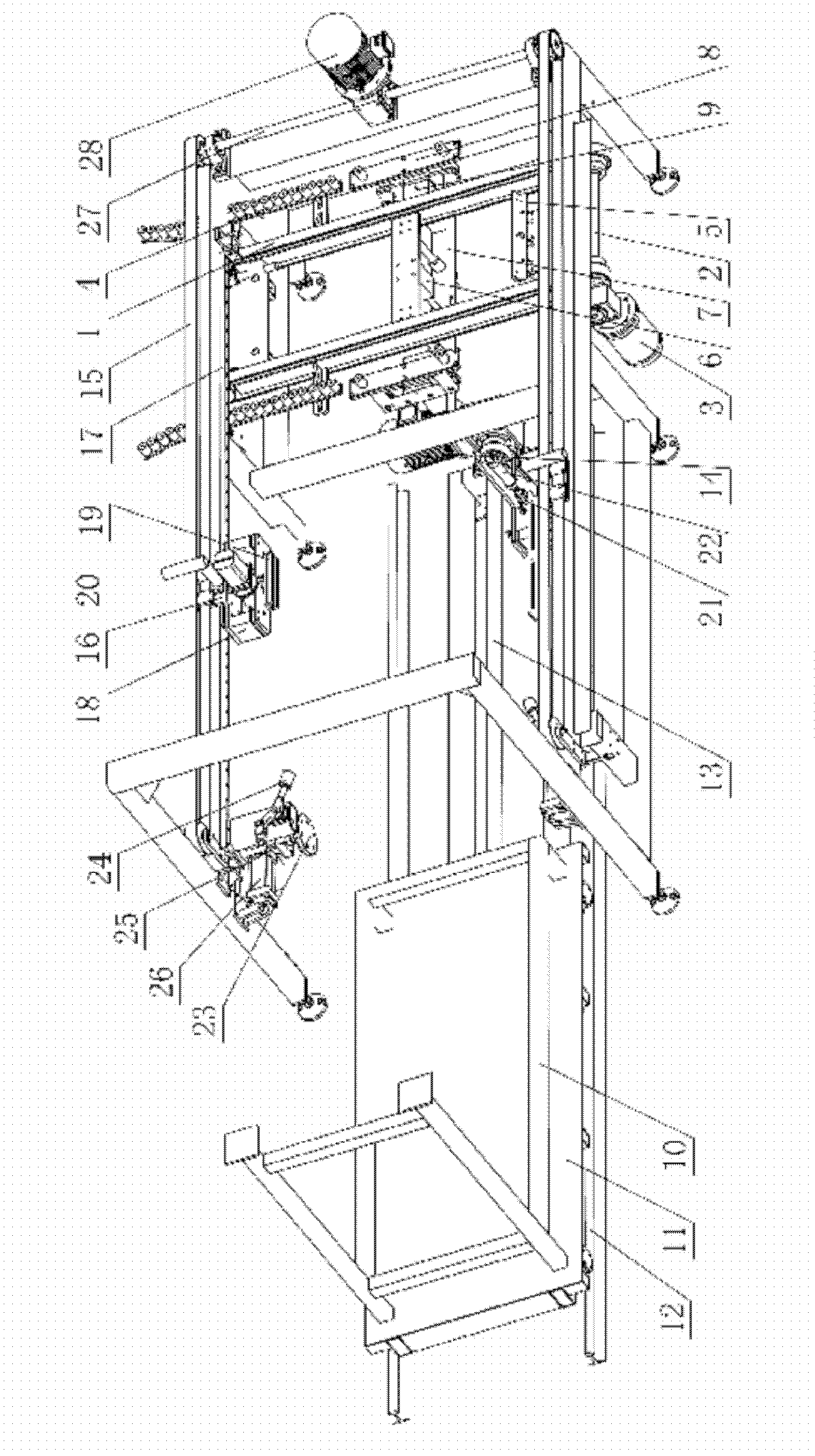

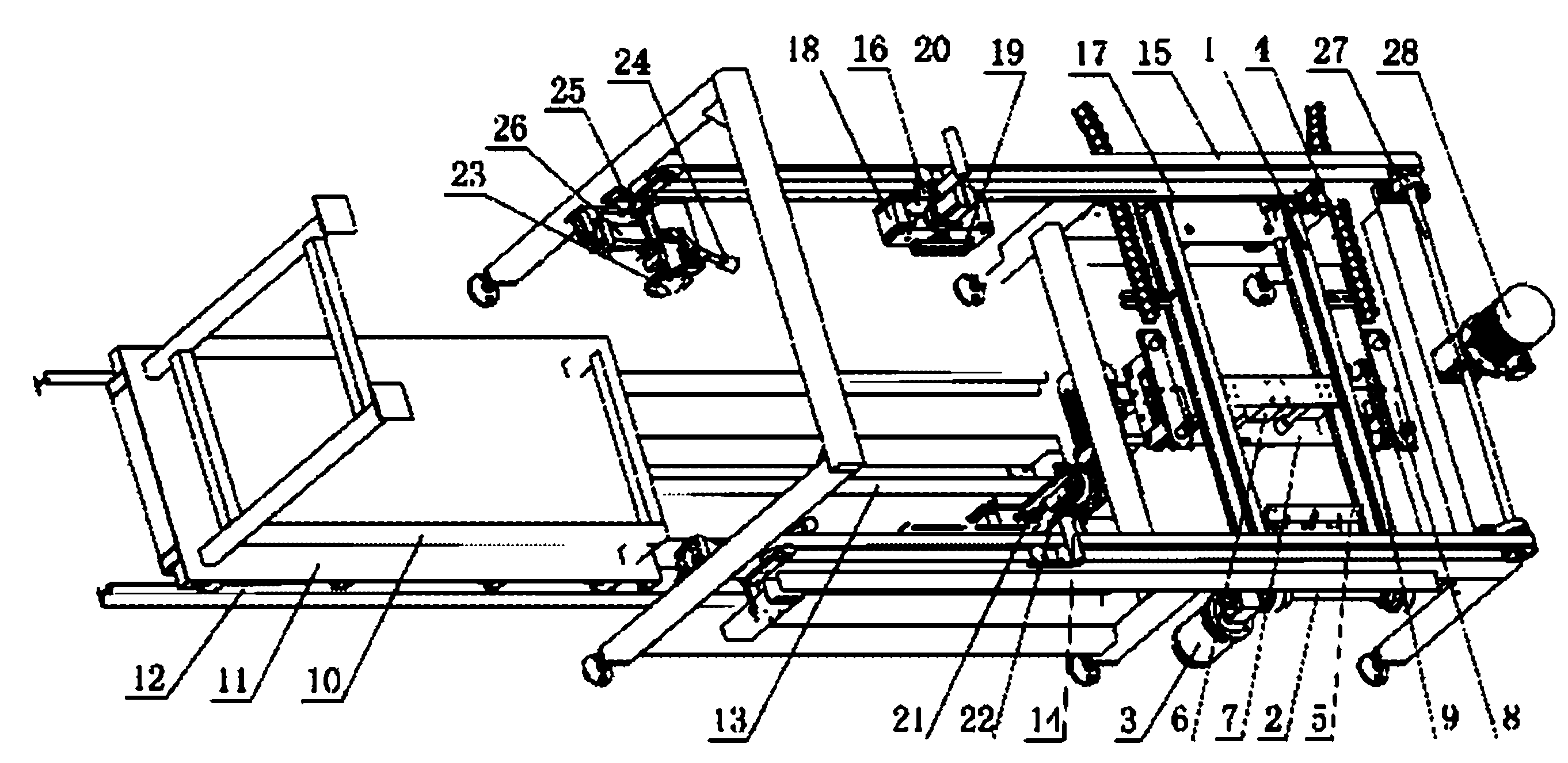

[0014] Such as figure 1 As shown, a sorting and stacking device for ceramic tiles, including a conveying mechanism for conveying ceramic tiles, installed on both sides of the input end of the conveying mechanism, and an introduction device for introducing ceramic tiles into the conveying mechanism, installed at the output end of the conveying mechanism , Brick blocking mechanism that can be raised and lowered to stop the conveying of ceramic tiles, the ceramic tiles blocked by the blocking mechanism can be lifted from the conveying mechanism, placed on the side of the conveying mechanism in the non-transporting direction, and the support bracket reciprocates The moving unstacking mechanism, placed above the conveying mechanism and the unstacking mechanism, moves back and forth to clamp the jacked-up ceramic tiles at both ends of the conveying direction, move the ceramic tiles to the top of the unstacking mechanism and turn the ceramic tiles to lean vertically The overturning t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com