Drilling and loading and transporting complete equipment for stone drift blasting driving

A complete set of equipment and blasting technology, which is applied to drilling equipment, drilling equipment and methods, mining equipment, etc., can solve the problems of poor continuity of manual or mechanical loading, poor safety, and high labor intensity, so as to improve walking Adaptability, improve stability, and ensure safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

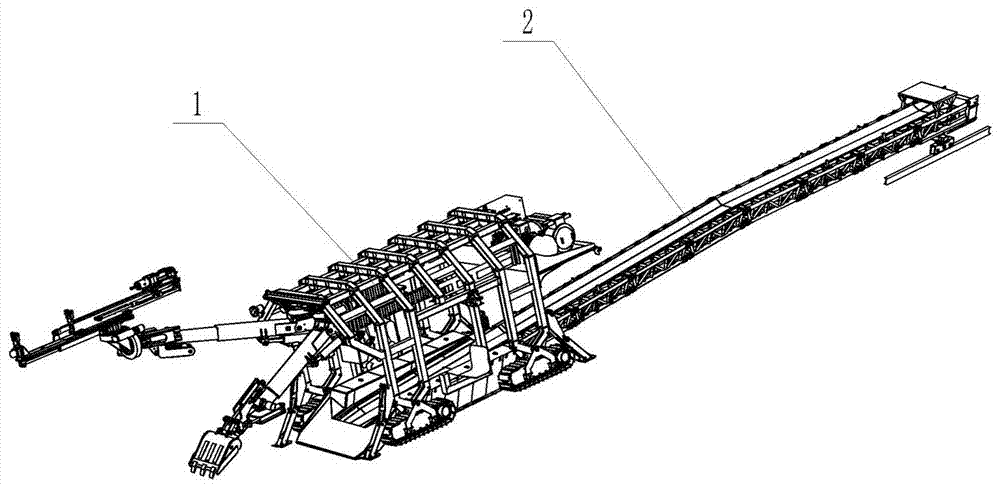

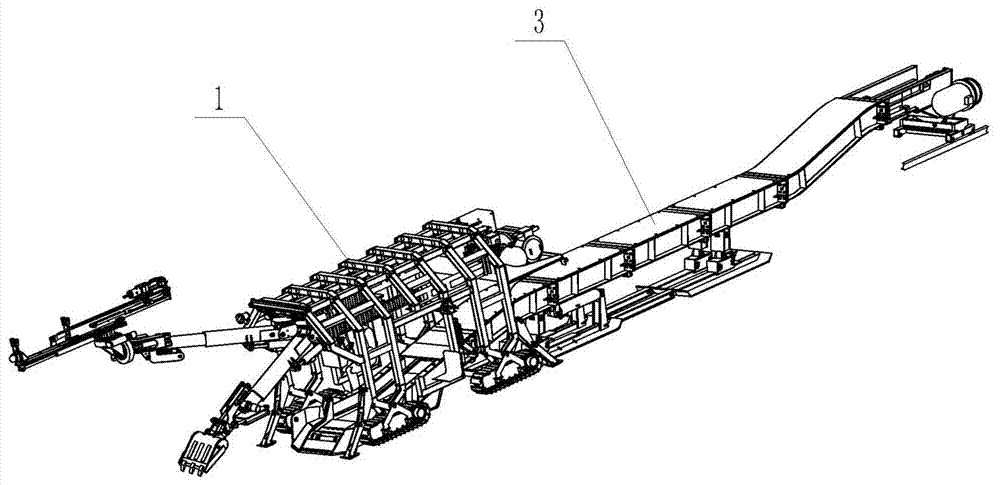

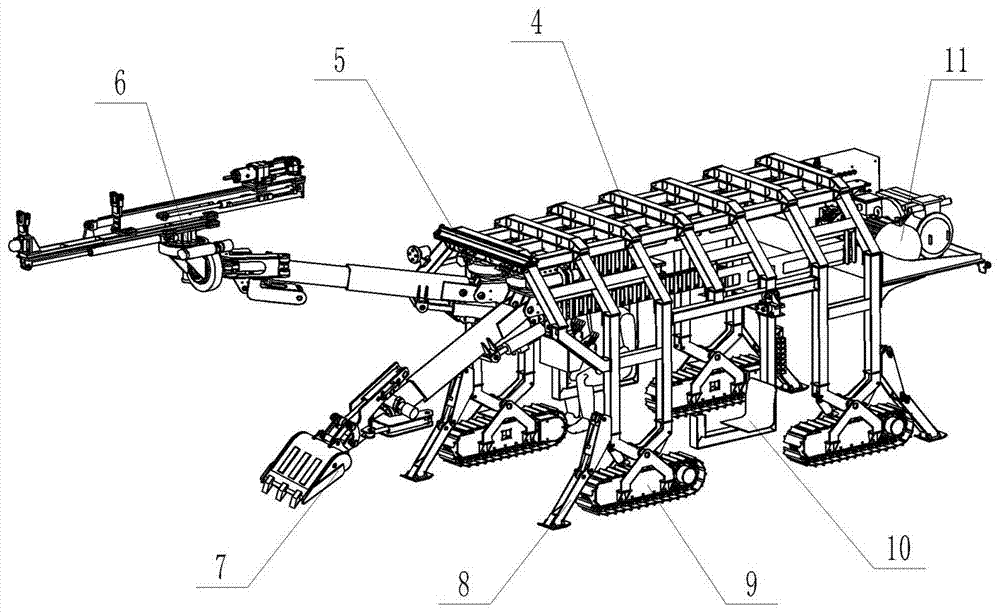

Embodiment Construction

[0052] The specific structure of the present invention will be described in detail in conjunction with the accompanying drawings. The complete set of equipment for rock tunnel drilling and drilling includes crawler support drilling machine 1 and material reloading and transportation device, according to Figure 3-12 As shown, the crawler support drilling machine 1 includes a frame support 4 with a transport space inside, and the front part of the frame support 4 is respectively provided with a drilling machine assembly 6 for drilling blastholes and anchor holes, and for shaping the roadway. 1. The cleaned bucket assembly 7, wherein the frame support 4 is composed of a top beam 12, a side beam 16 and a support beam 19. The frame support 4 is used to support the top beam 12 of the roof of the roadway, including several longitudinally arranged longitudinal beams 13 along the width direction of the roadway at equal intervals, and several parallel beams 13 arranged perpendicularly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com