Automated buoy recycling and laying device

A slewing device and buoy technology, applied in buoys, motor vehicles, transportation and packaging, etc., can solve the problems of high operation risk, difficult decoupling, increased navigation resistance, etc., achieve good safety and reliability, and expand the window period. , the effect of high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

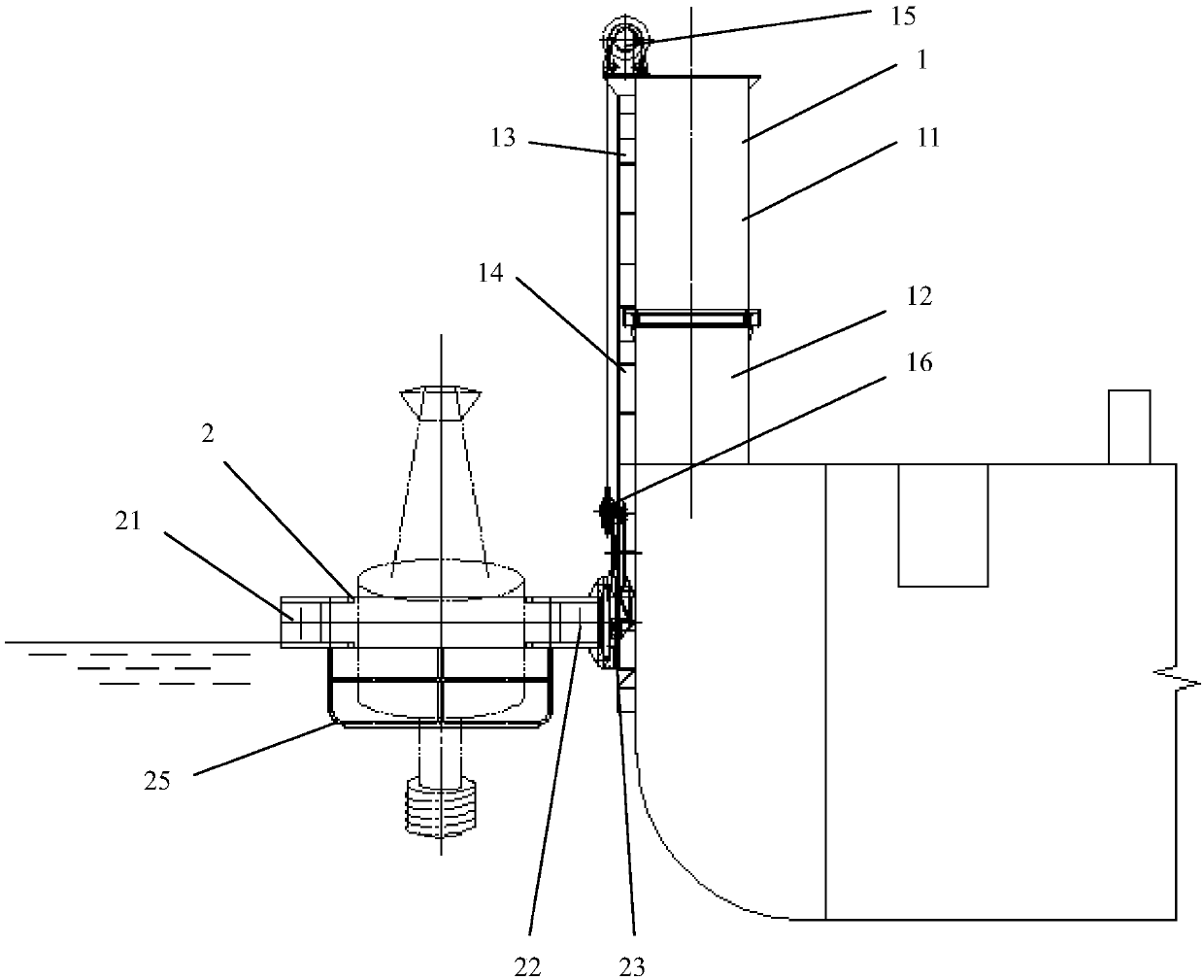

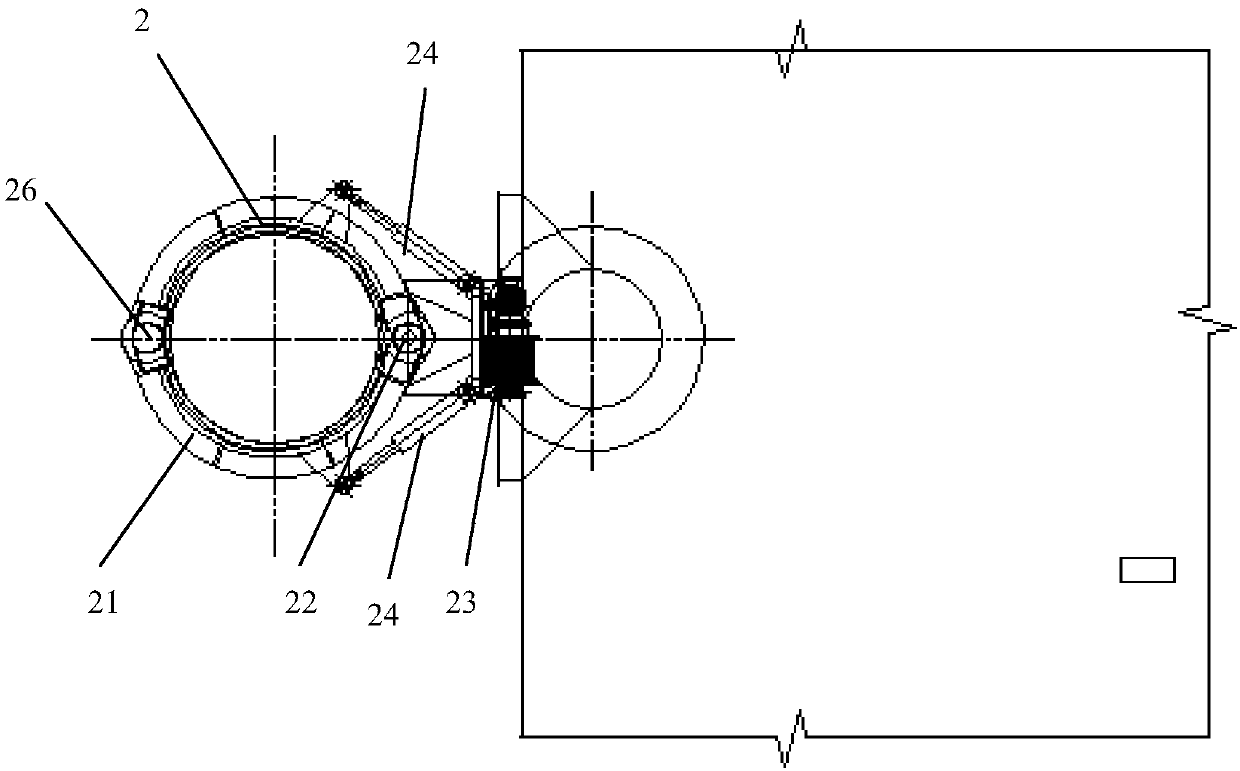

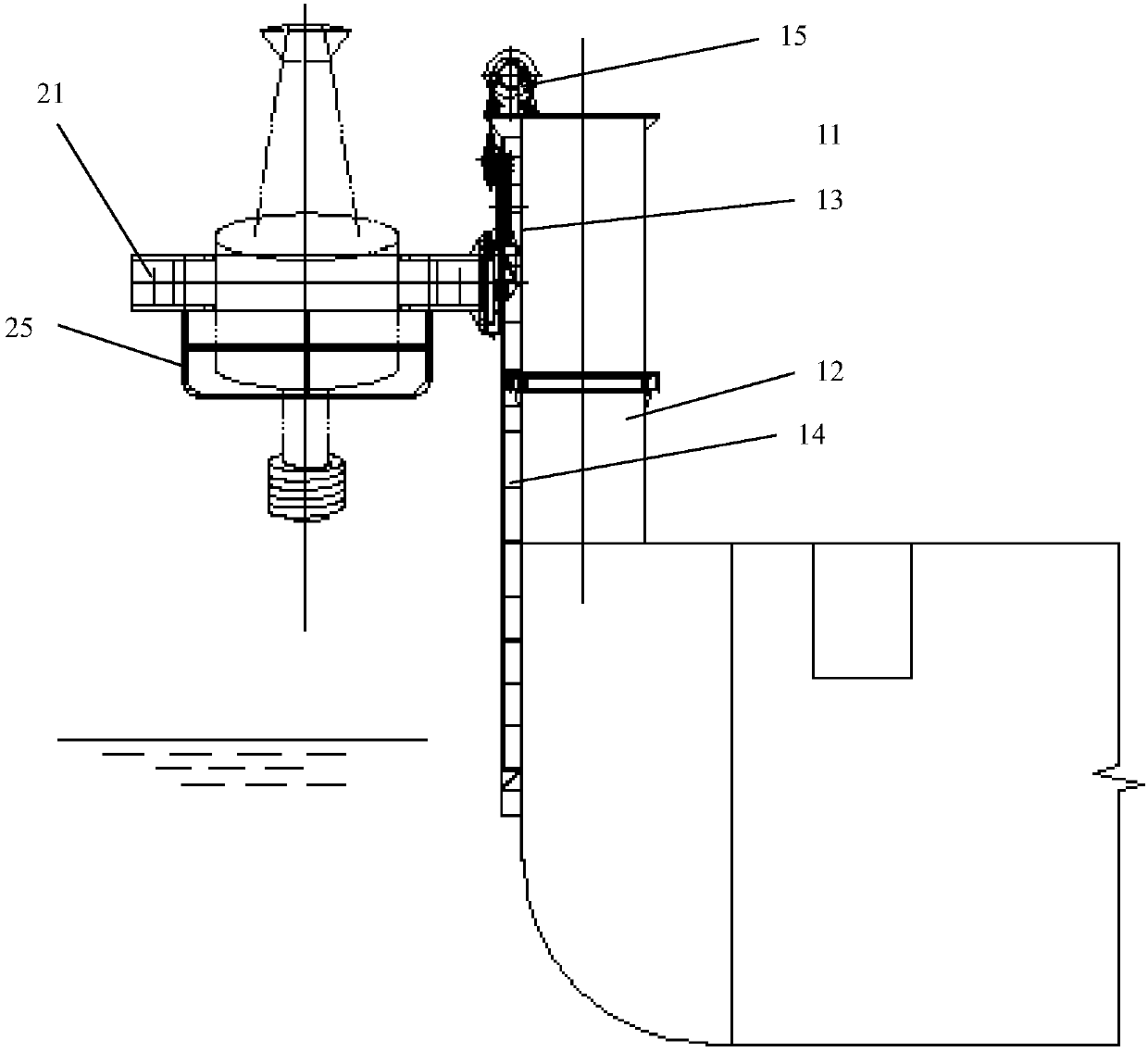

[0045] image 3 It is a lifting side view of the automatic buoy recovery deployment device of the present invention, Figure 4 It is a rotating side view of the automatic buoy recovery deployment device of the present invention, Figure 5 It is a top view of the rotation of the automatic buoy recovery deployment device of the present invention, Figure 6 It is a recovery side view of the automatic buoy recovery deployment device of the present invention, Figure 7 It is the recovery top view of the automatic buoy recovery deployment device of the present invention, please continue to see Figure 1 to Figure 7 shown.

[0046] In a further embodiment of the present invention, the buoy lifting and turning device 1 includes a turning upper part 11 and a turning lower part 12, the turning lower part 12 is fixedly connected with the hull, and the turning upper part 11 and the turning lower part 12 are connected by a turning mechanism, and the turning upper part 11 can The lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com