Construction method for large-gap drainage asphalt concrete pavement under assistance of warm mixing aid

A technology for draining asphalt and warm mix adjuvant, applied in the field of asphalt pavement, can solve the problems of reduced service life of the pavement and the turnover of the construction period, no way to adapt to the road, no way to reduce the mixing and other problems, so as to reduce the consumption of artificial tools and prolong the construction window. period, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

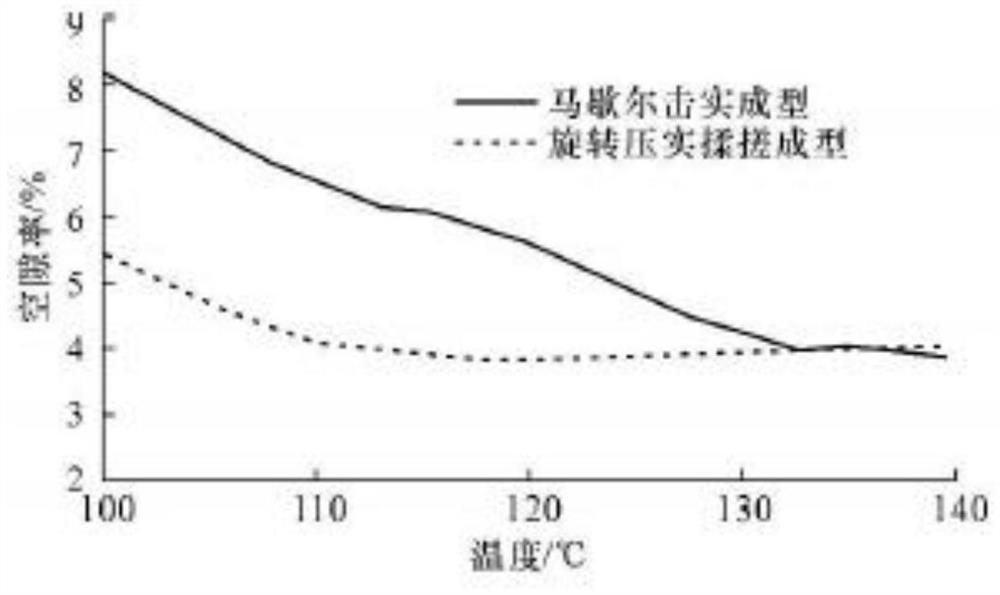

[0029] refer to Figure 1-2 , the construction method of asphalt concrete pavement with large void drainage under warm mixing additives, including the following steps:

[0030] In the present invention, preferably, the paving of the mixture; S1. Before paving, check whether the width and height of the screed of the paver are appropriate, and adjust the automatic leveling device.

[0031] S2. The left computer slide shoe of a paver is placed on the baseline, and the right computer slide shoe is placed on the baseline. During the paving process, check the layer thickness and cross slope at any time. If it does not meet the requirements, adjust it in time, and the paver will move forward. Maintain a constant speed during the process, but it can be adjusted appropriately accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com