Anti-unscrewing and multi-angular fastening apparatuses and methods for surgical bone screw/plate systems

A fastening device and anti-loosening technology, applied in the direction of outer panels, threaded fasteners, screws, etc., can solve problems such as difficult angle arrangement and screw drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Reference will now be made in detail to the presently preferred embodiments of the subject matter, one or more examples of which are illustrated in the drawings. The various examples are provided to illustrate the subject matter, not by way of limitation. Indeed, features illustrated or described as part of one embodiment can be applied to another embodiment to yield yet another embodiment. The intent is for this topic to cover such modifications and variations.

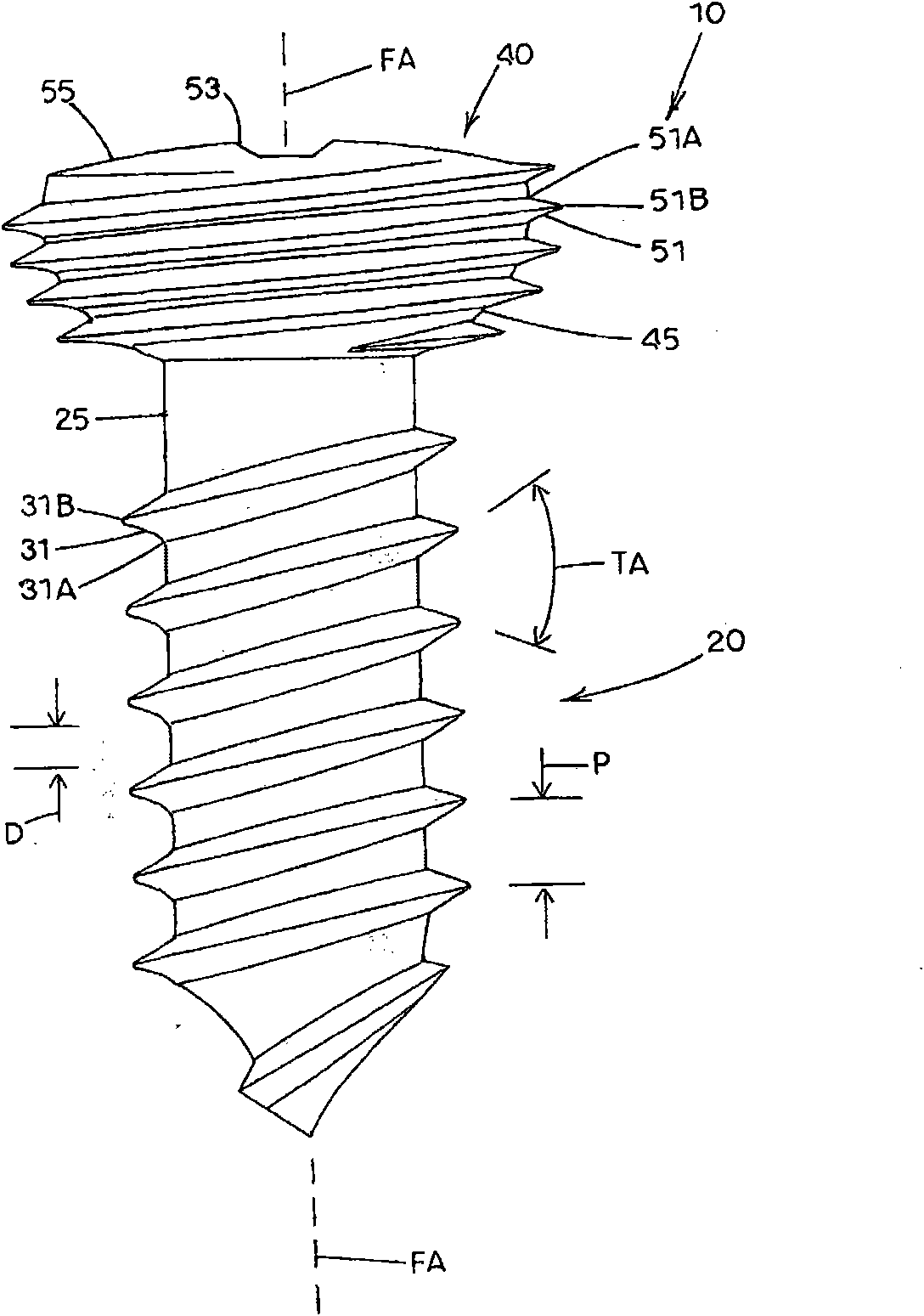

[0039] reference now figure 1 , illustrating one embodiment of a threaded head fastener in accordance with the present disclosure, generally designated 10 . Fastener 10 may be made of any material suitable for withstanding compression, tension, torsion, or other forces encountered during and after application of fastener 10 to a target location. In the context of orthopedic surgery, the fastener 10 is preferably made of a biocompatible metal or metal alloy, such as stainless steel, titanium, chromium or all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com