Earth pressure balance shield machine cutterhead

An earth pressure balance and shield machine technology, which is applied in earth-moving drilling, mining equipment, tunnels, etc., can solve the problems of increasing the load of the cutter head motor, severe damage, and wear of the cutter head motor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

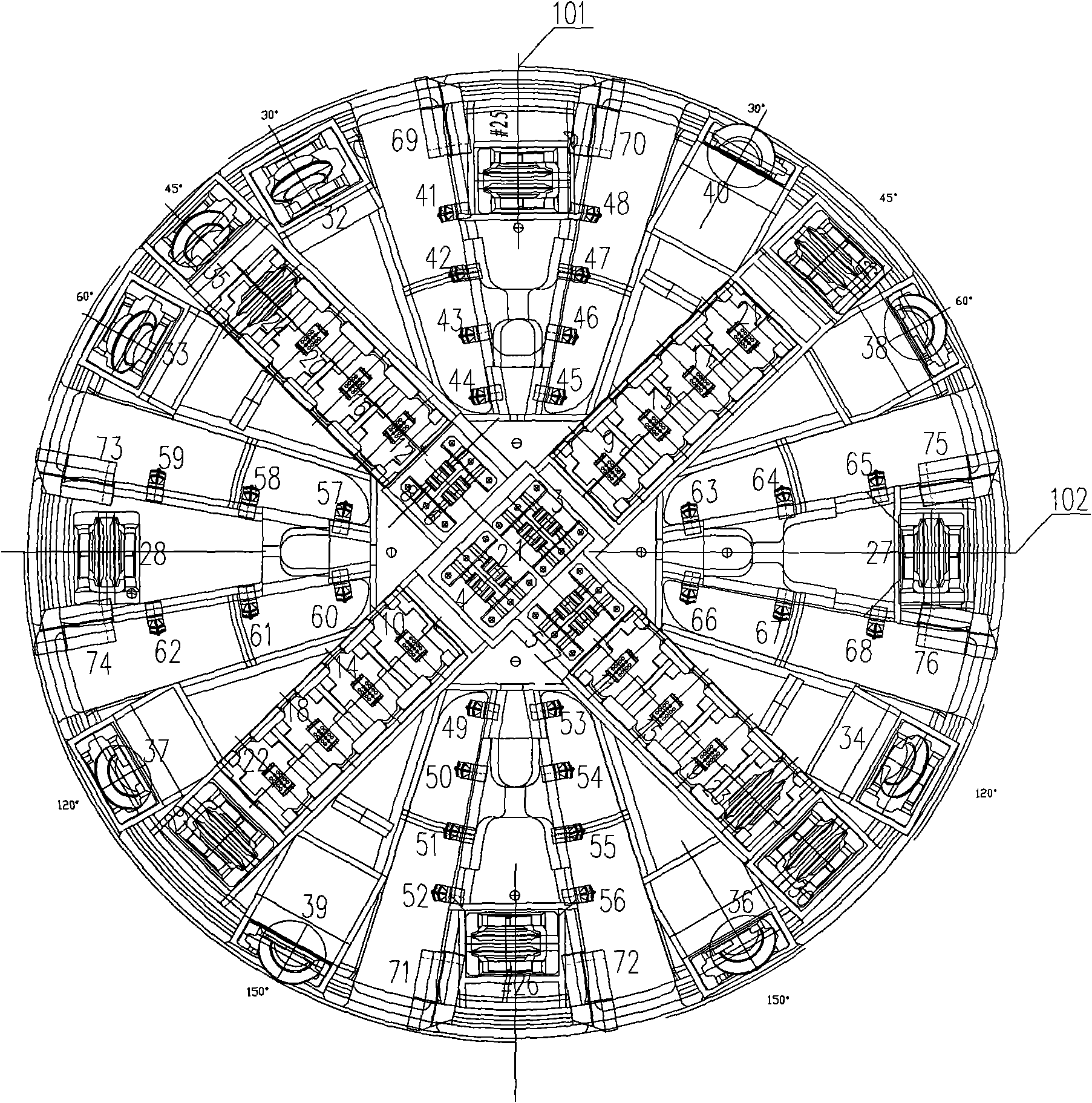

[0027] like figure 1 The cutter head of the earth pressure balance shield machine shown, the cutter head layout can be divided into the central area, the front area and the edge area.

[0028] Central area: Set 1#-8# knife holders, and double-edged toothed cutters are installed in the knife holders; taking the center of the cutterhead as the origin, the rotation radii of 1#-8# double-edged toothed cutters are 120mm, 170mm, 280mm, 340mm, respectively. 468mm, 542mm, 628mm, 705mm.

[0029] Front area: with the longitudinal cross line 101 of the cutter head as the center line, the 9#-31# knife holders are arranged in the 9#-31# knife seat at an angle of (±)45°; the cutter head is vertically and horizontally (0°, 90 °) A small scraper is arranged on the 41#-68# knife seat near the notch of the cross line (101, 102). Taking the center of the cutter head as the origin, the rotation radii of 9#-22# single-edged tooth cutters are 800mm, 900mm, 1000mm, 1100mm, 1200mm, 1300mm, 1400mm, ...

Embodiment 2

[0032] The difference with embodiment 1 is:

[0033] The 10#-14# knife holders and 16#-19# knife holders in the front area are arranged with single-edged tooth cutters, and the 9#, 15#, 20#-31# knife holders are arranged with double-edged hobs;

[0034] The 32-40# knife holders in the edge area are arranged with double-edged hobs, and the 69#-76# knife holders are arranged with side scrapers.

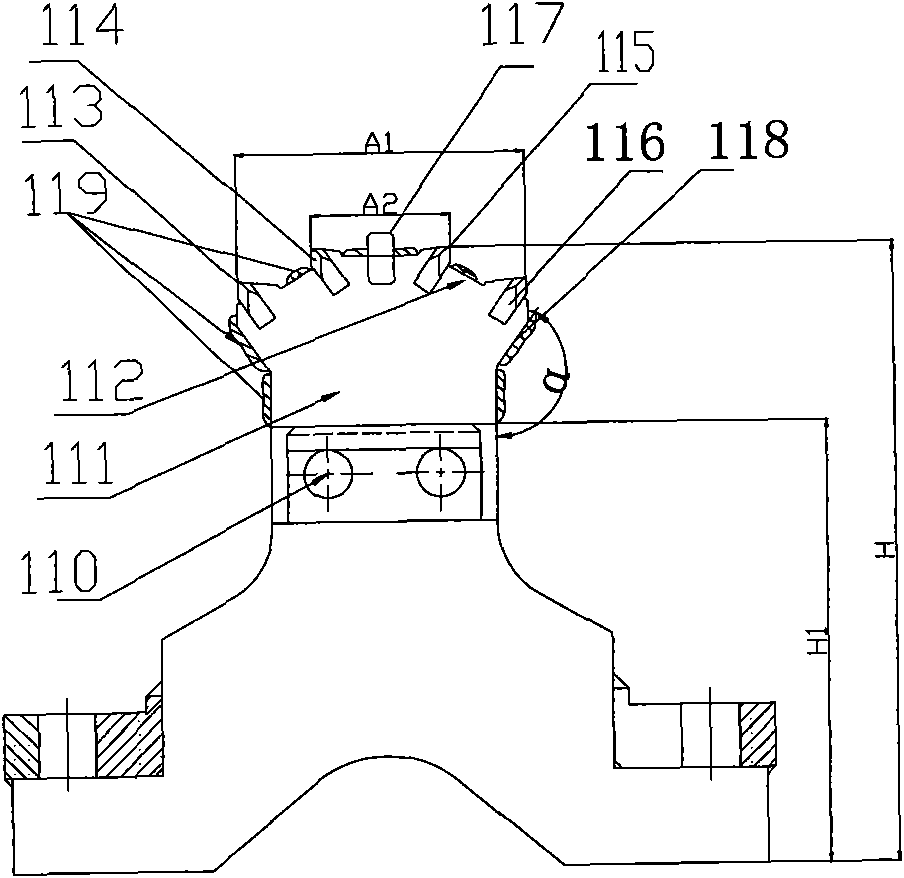

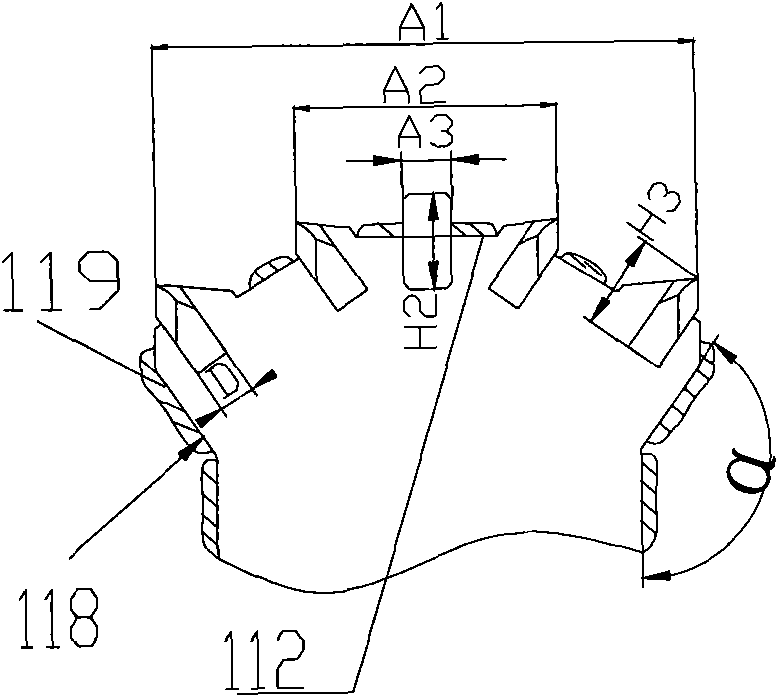

[0035] The double-edged serrated cutter described in above-mentioned embodiment 1 and 2 is as Figure 2-5 As shown, the lower parts of the two cutter heads 122 are respectively tightly fitted with the corresponding cutter body 121 by the bolts 110 and then welded to strengthen the connection strength between the cutter head and the cutter body. The knife body is fixedly connected in the knife seat. The cutter body height H1 is 277mm. The distance B between the outer surfaces 111 of the two cutter heads is 254mm, and the distance B2 between the inner surfaces 124 is 70mm; the length A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com