Rock lane digging method

A rock roadway and rock technology, which is applied in the field of rock roadway excavation combining controlled blasting technology and roadheader tunneling technology, can solve the problems of roadheader pick loss, poor reliability and adaptability, and low efficiency, so as to increase the speed of tunneling , increase safety and reduce cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0035] A preferred embodiment of the rock roadway excavation method of the present invention is:

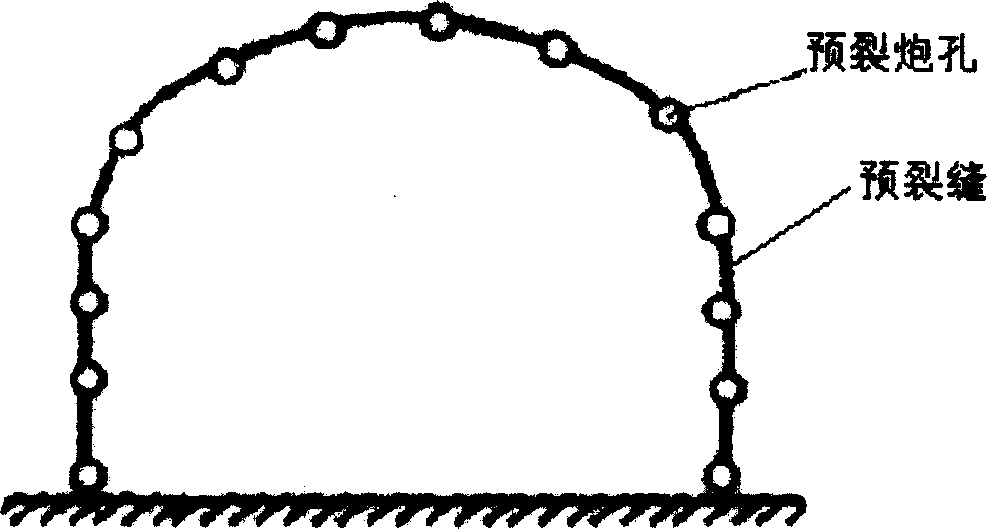

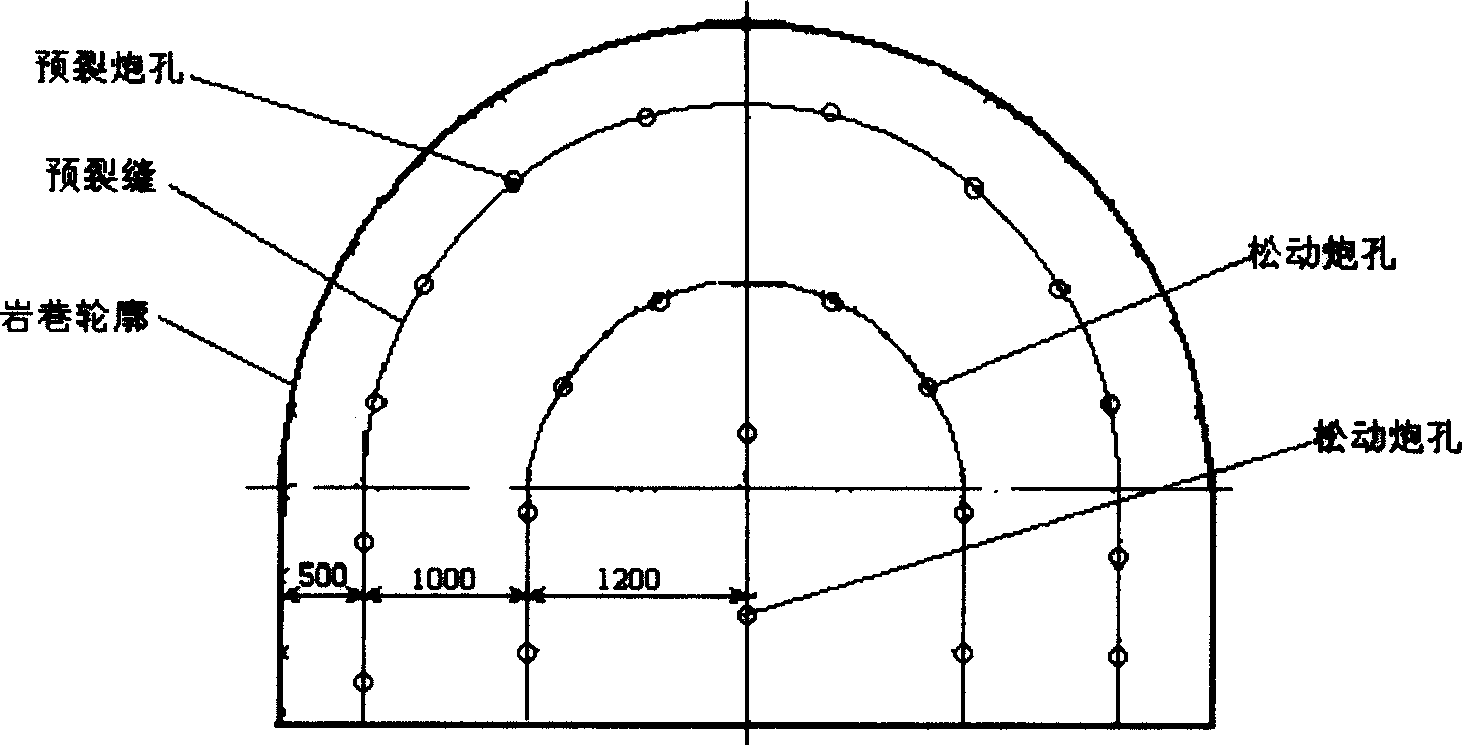

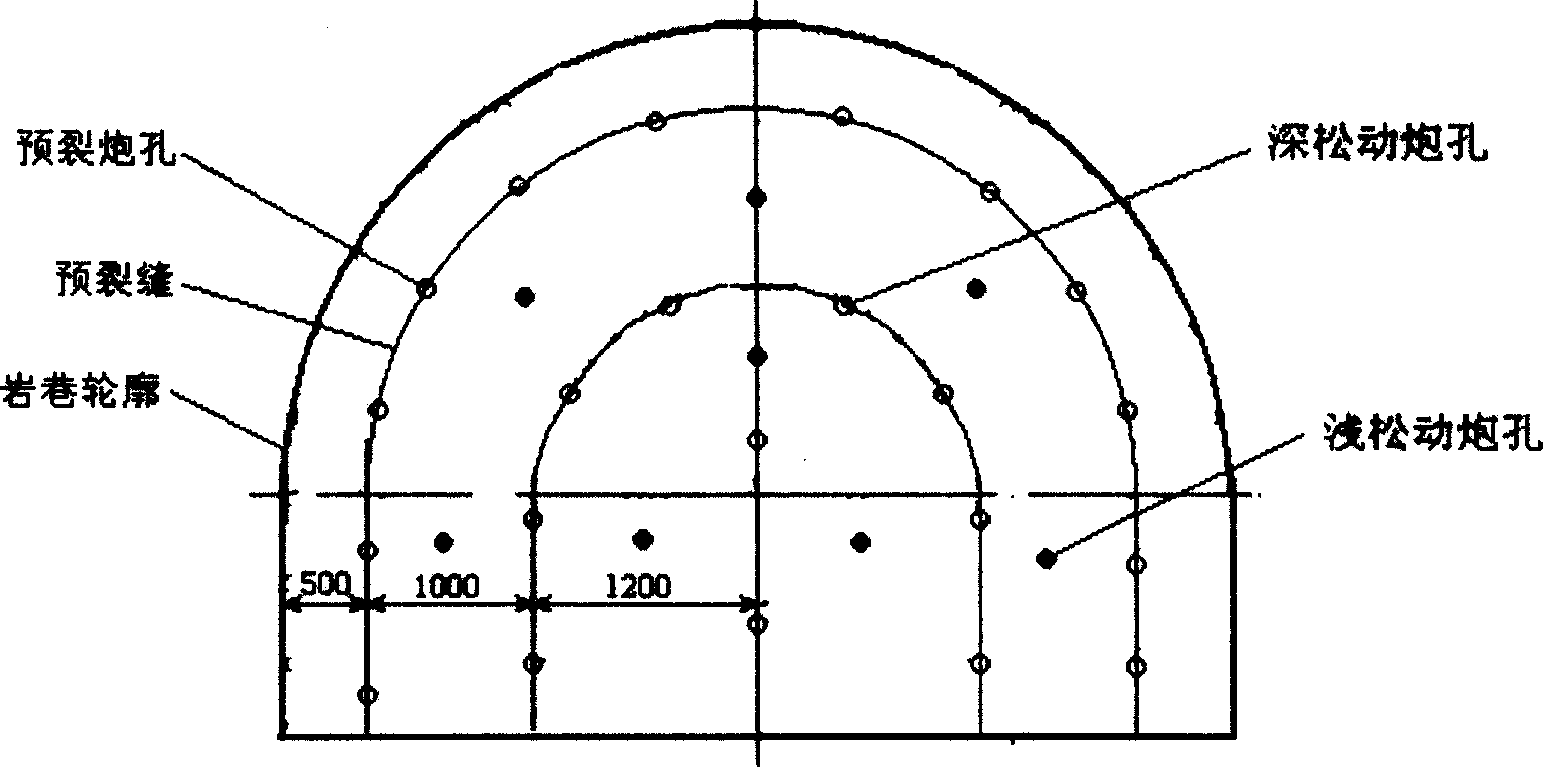

[0036] like figure 1 As shown, the directional blasting technology is firstly used to arrange a number of pre-splitting blastholes and guide holes near the periphery of the rock roadway, and then an appropriate amount of explosives are loaded into the pre-splitting blastholes for directional blasting to form pre-cracks;

[0037] Then adopt the loosening blasting technology to arrange multiple loosening blastholes on the rock working face of the rock roadway, and then according to the characteristics of the rock, put an appropriate amount of explosives into the loosening blastholes, and perform loosening blasting to break the rock in the pre-crack;

[0038] Finally, the roadheader is used to excavate the loose rock in the roadway.

[0039] Both directional blasting and loose blasting belong to controlled blasting.

[0040] Using directional blasting technology to form pre-cracks...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com