'Three-soft' low permeability high gas coal seam rapidly digging method

A gas-permeable, coal seam technology, applied in the direction of gas discharge, earthwork drilling, safety devices, etc., can solve problems such as slow working speed, gas cannot be removed in time, reduce construction procedures, improve gas drainage effect, and ensure safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

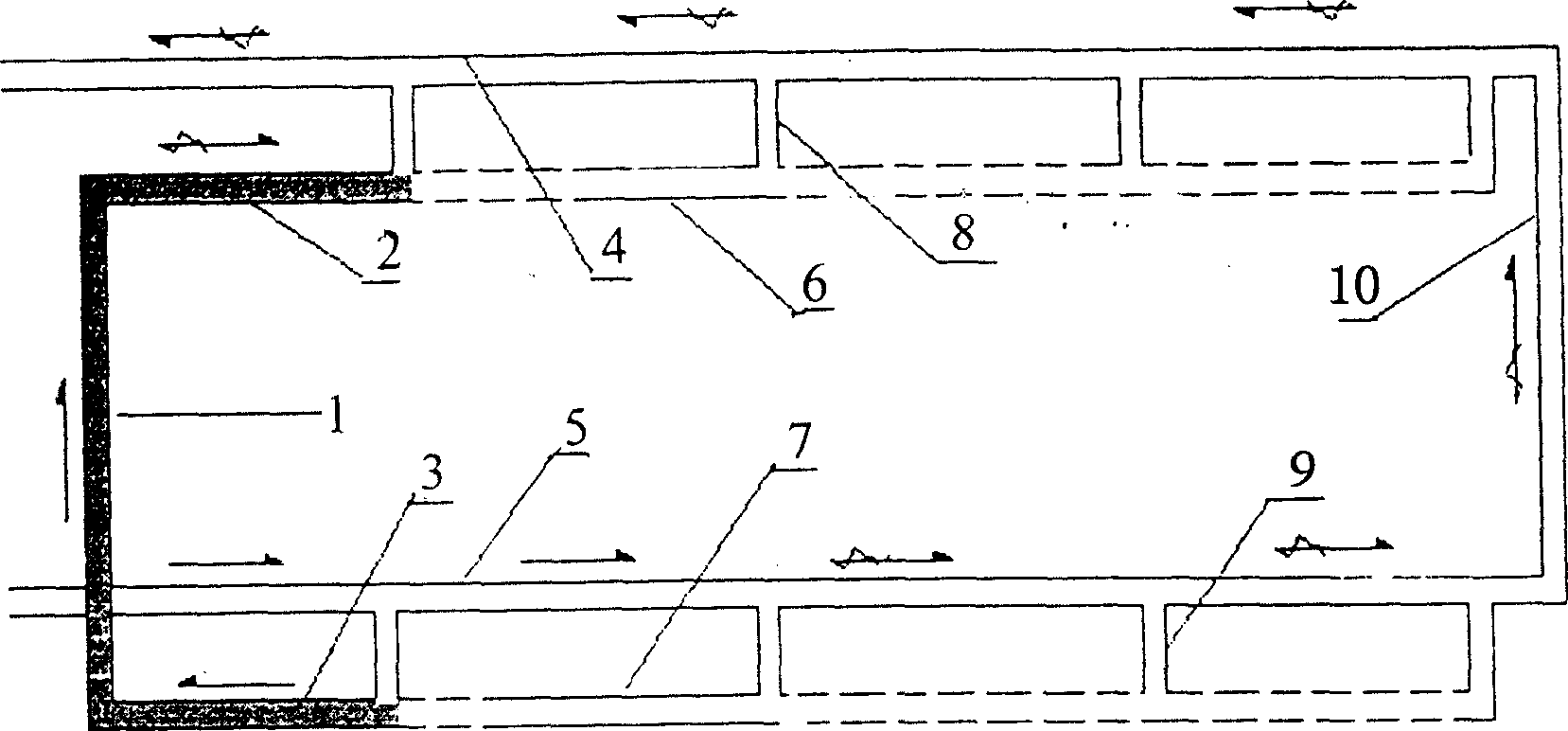

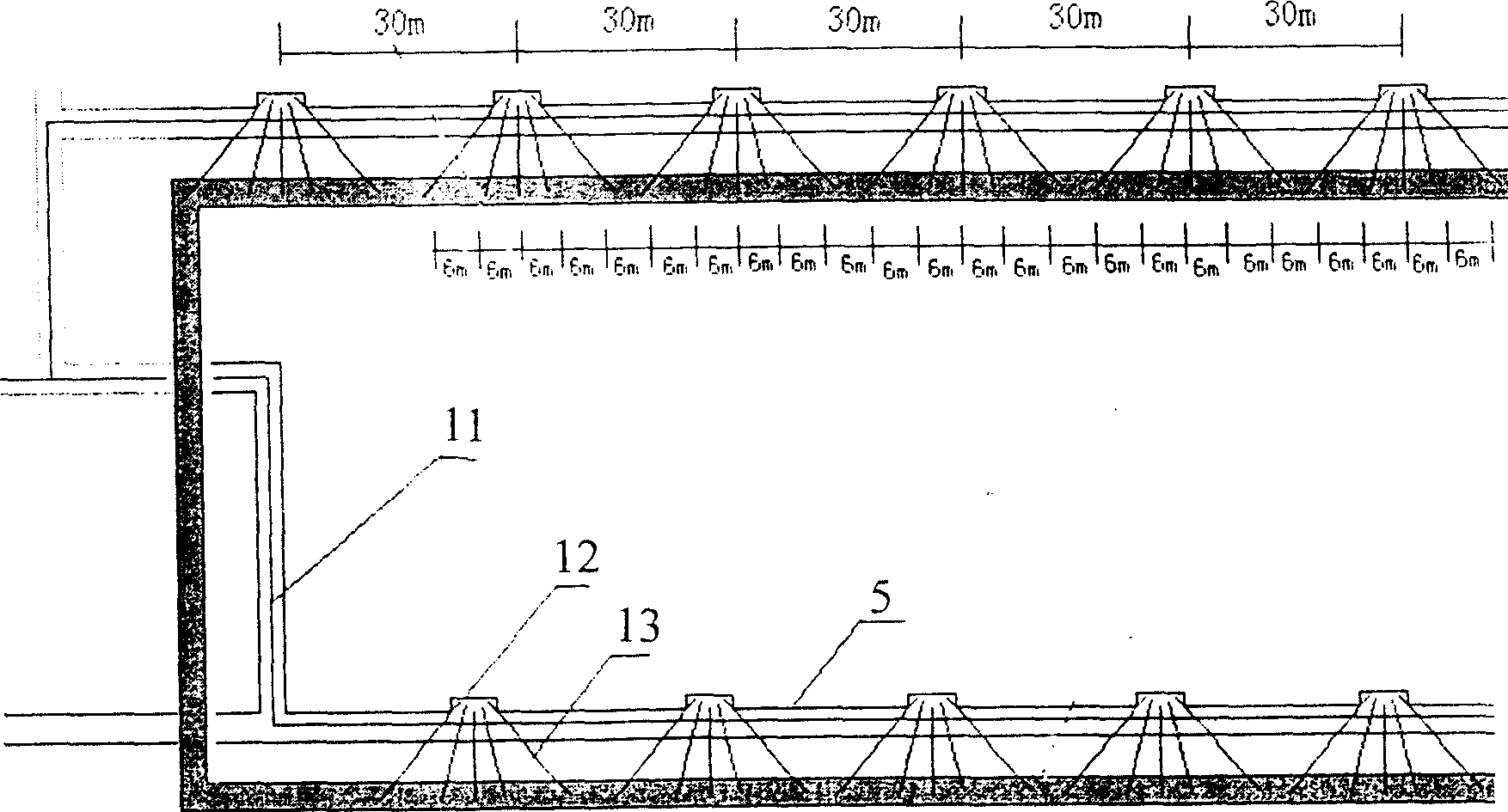

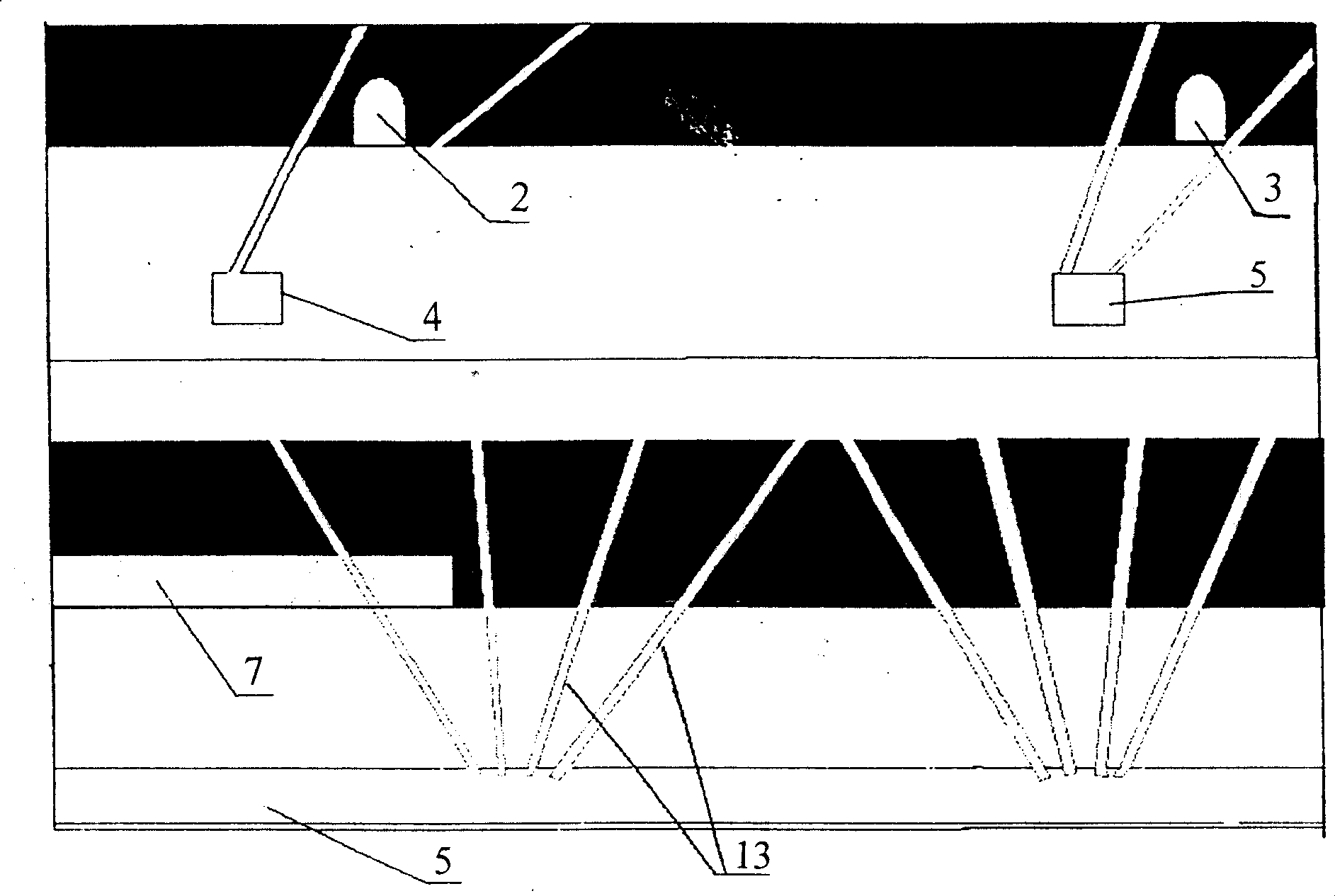

[0025] Depend on figure 1 It can be seen that: in the upper and lower limestone of the coal seam mining face 1, the floor rock roadway is arranged according to the direction of the mining face. Because the rock layer is hard and stable, the naked roadway can be constructed, thereby increasing the excavation speed; figure 2 It can be seen that: after the formation of a complete ventilation system 11 in the upper and lower rock roadways of the bottom slate, the layer-crossing drilling 13 for gas pre-pumping is performed;

[0026] Depend on figure 1 It can also be seen that the bottom slate roadway is two connected upper and lower rock roadways, and the upper rock roadway 4 on the bottom slate is set on the top of the tunnel 2 on the working face 1 of the coal seam mining face 1 and advances the coal roadway 6 along the upper tunnel. The lower rock roadway 5 of the floor rock is set at the lower side of the down trough 3 of the working face of the coal seam mining face 1 and ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com