Roadheader

A technology for roadheaders and roadways, which is applied to cutting machinery, slitting machinery, driving devices, etc., can solve the problems that the cutting part can not achieve fixed-point cutting due to the small lateral swing range, and achieves flexible cutting, convenient operation, and improved The effect of tunneling speed and ergonomics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

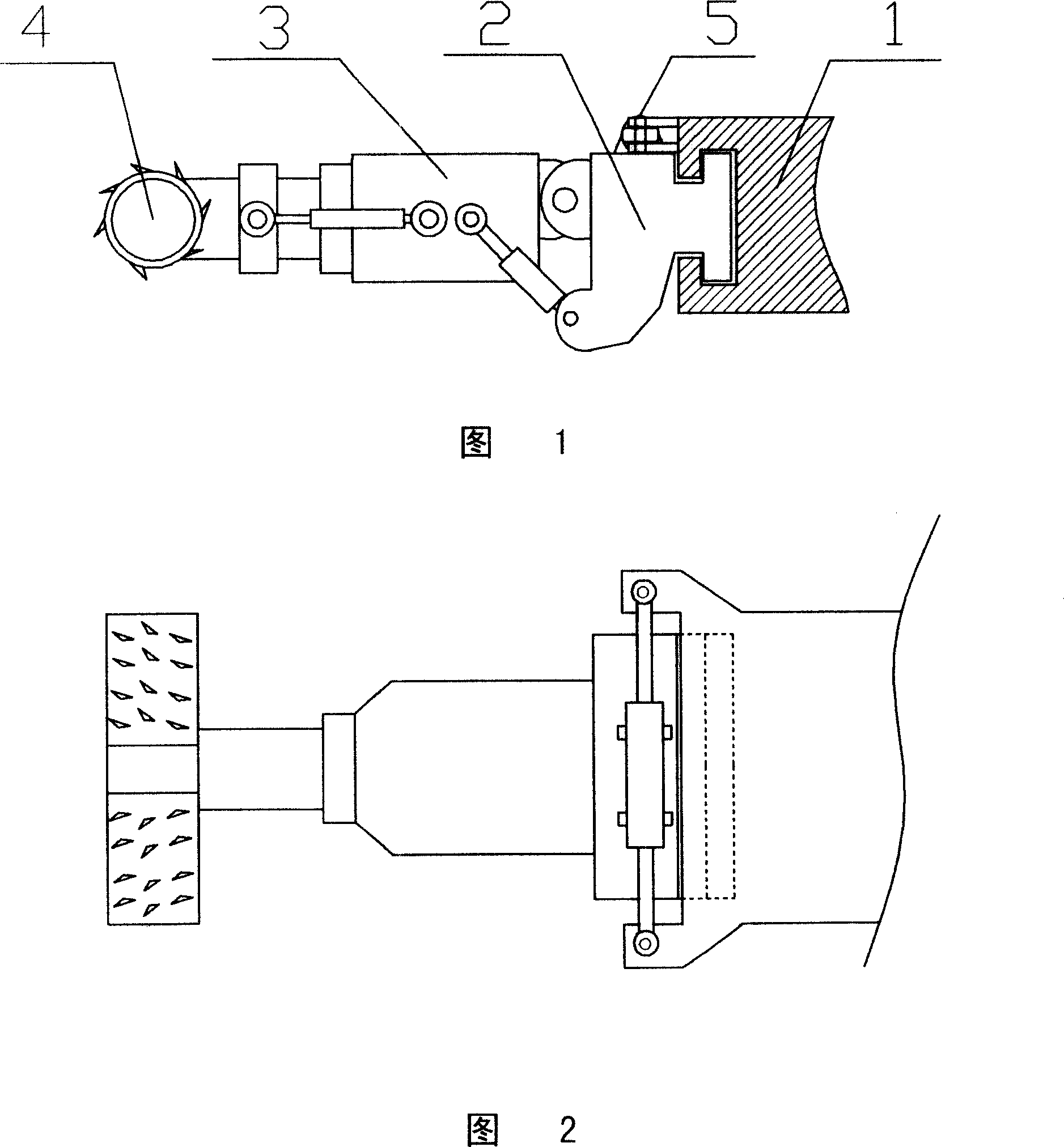

[0028] A configuration of the cutting section of the road boring machine according to the invention is shown in FIGS. 1 and 2 . It is mainly composed of a cutting drum 4, a cantilever 3, a cutting motor, a cutting reduction box, a telescopic part and a telescopic oil cylinder, etc.

[0029] The rear end of the cantilever 3 is connected with the main body, or frame, through a horizontal and transverse sliding guide mechanism. The sliding guide mechanism comprises a carriage 2 hinged at the rear end of the cantilever 3 and a guide seat 1 fixedly connected to the front part of the main body. The rear end of the carriage 2 has a T-shaped guide body, and the front end of the guide seat 1 has a horizontal and transverse T-shaped guide groove. The T-shaped guide body of the carriage 2 is embedded in the T-shaped guide groove of the guide seat 1 and corresponds to it. Slip fit.

[0030] Between the guide seat 1 and the carriage 2, a driving component oil cylinder 5 is arranged. The...

Embodiment 2

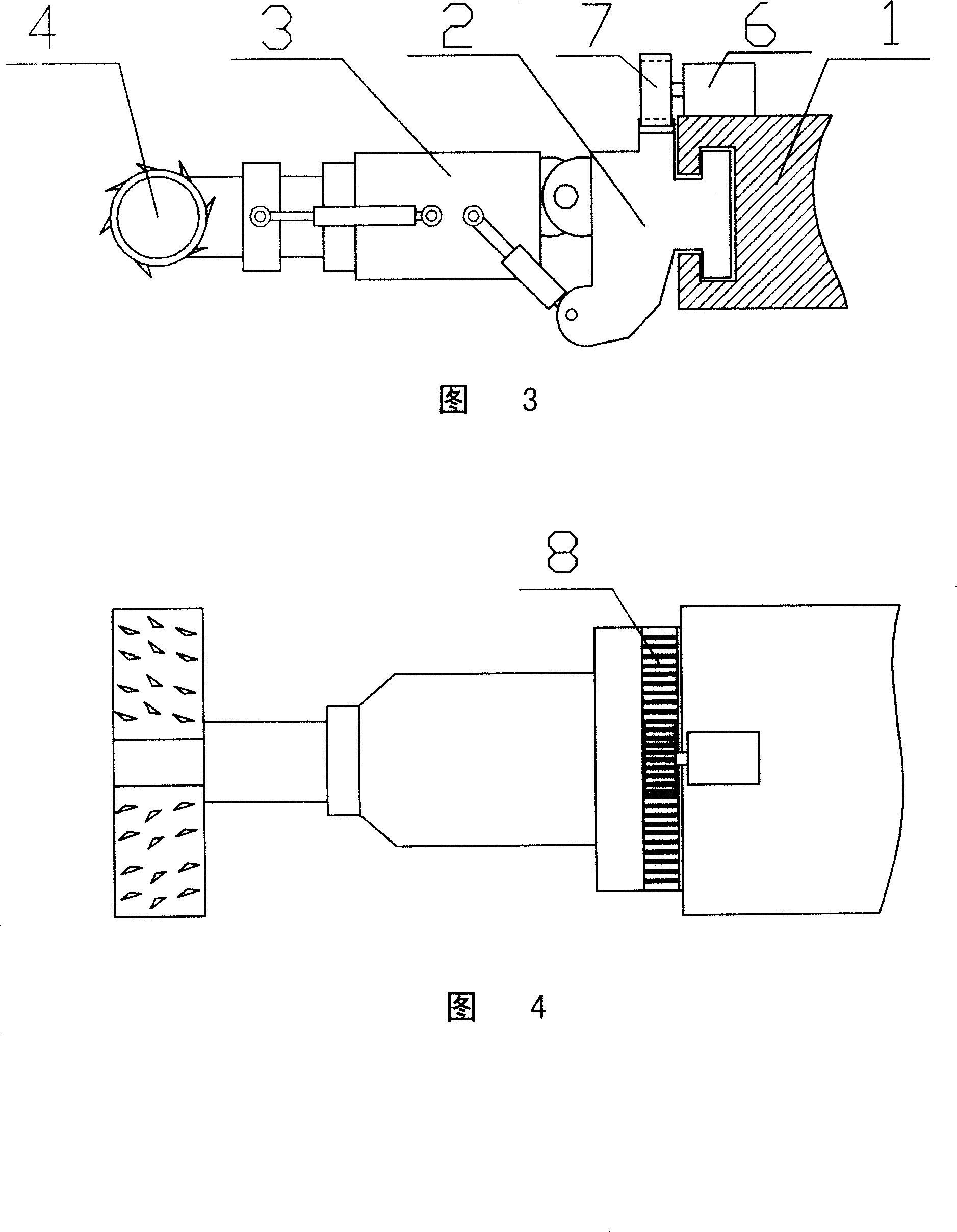

[0035] Another configuration of the cutting section of the roadheader according to the invention is shown in FIGS. 3 and 4 . Its structure is basically the same as that of Embodiment 1, the difference is that: the driving part for driving the carriage 2 to move horizontally and laterally between the guide seat 1 and the carriage 2 is composed of a hydraulic motor 6 , a gear 7 and a rack 8 . The hydraulic motor 6 is fixed on the guide seat 1, the gear 7 is fixedly connected to the output shaft of the hydraulic motor 6, the rack 8 is fixedly connected to the carriage 2, and is horizontally arranged, and the gear 7 and the rack 8 mesh. When the hydraulic motor 6 rotates, the gear 7 drives the rack 8 to move left and right, driving the sliding frame 2 and the cutting part to move horizontally and laterally as a whole.

Embodiment 3

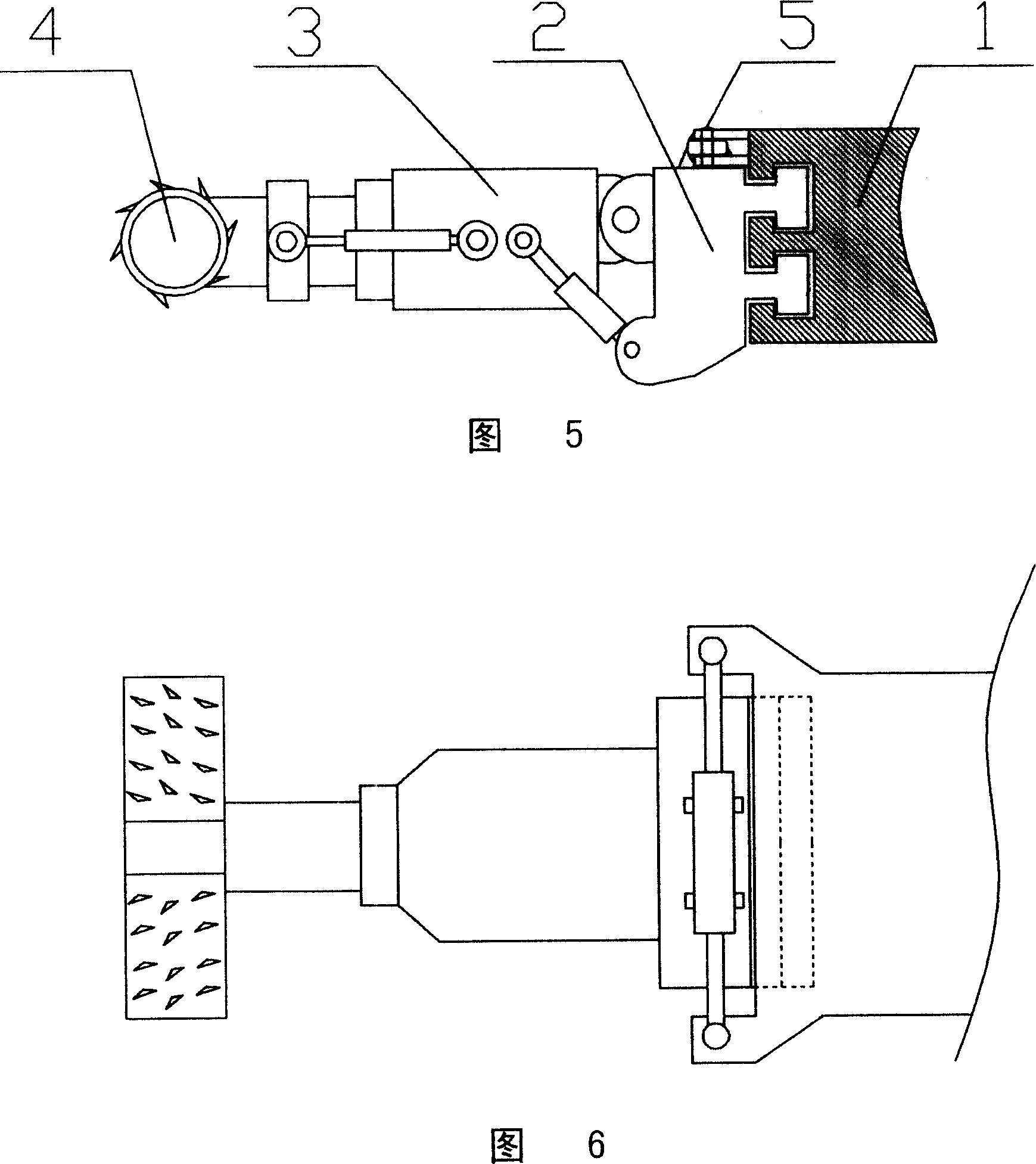

[0037] A third structure of the cutting section of the roadheading machine of the present invention is shown in FIGS. 5 and 6 . Its structure is basically the same as that of Embodiment 1, the difference is that there is a pair of T-shaped guide bodies at the rear end of the carriage 2, a pair of T-shaped guide grooves on the guide seat 1, and a pair of T-shaped guide bodies on the carriage 2. It is correspondingly embedded in the double T-shaped guide groove of the guide seat 1, and is slidably fitted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com