Excavation construction method for mine hard rock roadway

A construction method and technology for wells and roadways, which are used in mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of high requirements for wells and roadways support, poor engineering quality, unreliable safety, etc., and achieve stable construction and cutting without vibration. The effect of low energy consumption and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

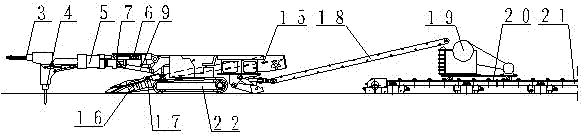

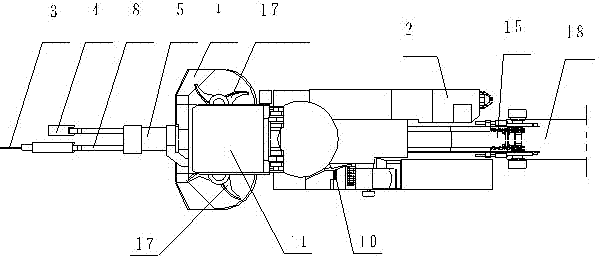

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] The present invention a kind of tunneling construction method of mine hard rock shaft roadway, and its steps are:

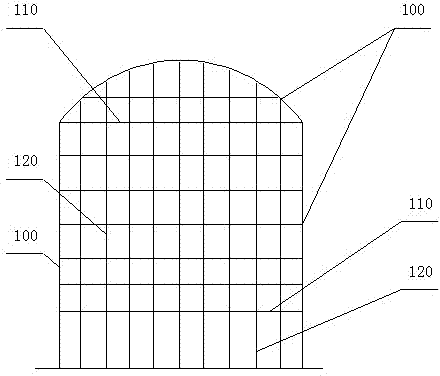

[0030] 1) According to the design requirements and according to the section shape of the roadway, the outer contour of the roadway is first cut out with the cutting device of the tunneling device to obtain the outer contour groove; the upper part of the outer contour groove is an arc, and the left and right two grooves are vertical line, forming an outer contour structure with an arched upper part and a rectangular lower part; the depth of the outer contour groove is generally 0.6-1.2 meters, and the width is slightly larger than the thickness of the chain of the cutting device (hydraulic chain saw);

[0031] 2) Use a cutting device to cut in the horizontal and vertical directions in the roadway section (inside the outer contour groove) t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com