Mine Shaft Chainsaw Hard Rock Tunneling Machine

A technology for hard rock roadheaders and chainsaws, applied in the directions of propulsion, cutting machinery, slitting machinery, etc., can solve the problems of short service life of picks, low driving construction efficiency, and increased construction costs, so as to reduce driving costs. , The effect of eliminating the blasting process and saving operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

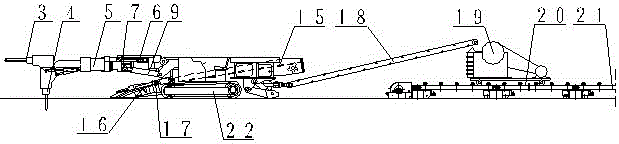

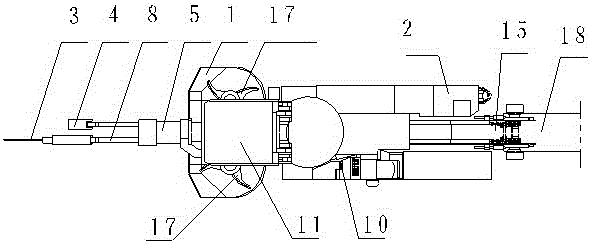

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0024] see figure 1 , 2 , a mining roadway chainsaw type hard rock roadheading machine, including a body 1 hydraulic device 2, the body 1 is a support frame body of the roadheader, used to support the relevant parts of the roadheader and install these parts. The hydraulic device 2 is arranged on the main body 1, including the existing hydraulic pump station, control box, hydraulic oil tank and hydraulic pipelines, etc., to provide hydraulic power for the roadheader; as a structure of the prior art, no further description is given here .

[0025] At the front end of the main body 1, a hydraulic chainsaw 3 and a hydraulic crushing head 4 are provided. The hydraulic chainsaw 3 and the hydraulic crushing head 4 are respectively connected to the hydraulic pipelines of the hydraulic device 2. Cutting or breaking action, acting on the rock in the shaft. Hydrauli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com