Underground coal mine auto-drilling apparatus and method

A technology of drilling device and drilling method, applied in safety devices, mining equipment, earth-moving drilling, etc., can solve the problems of hole collapse, stuck drill, top drilling, etc. Safe, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

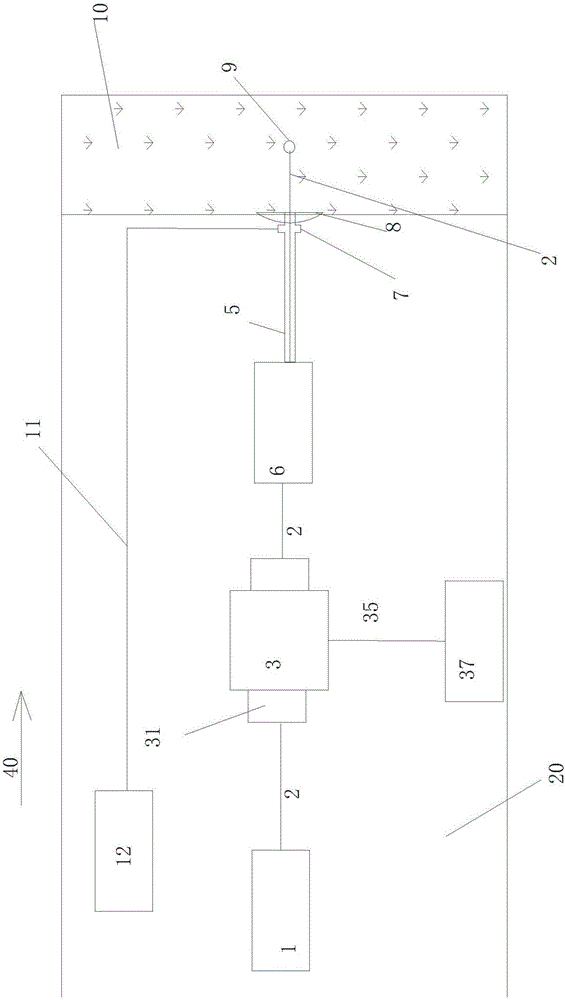

[0033] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

[0034] Such as figure 1 As shown, the present invention proposes a coal mine underground automatic drilling device, which is installed in the underground tunnel 20 of the coal mine, for example, used for horizontal drilling, or drilling with a large inclination angle, to extract gas and improve the efficiency of gas extraction. The coal mine automatic drilling device includes:

[0035] The pressurized pump truck 1, that is, the high-pressure pump truck, pressurizes the liquid (water) input into the coiled pipe; The rated power of pump truck 1 can be 250KW;

[0036] The coiled tube 2 is a metal tube, and the coiled tube has an inlet and an outlet. The inlet of the coiled tube is connected to the pressurized pump truck 1; the outlet of the coiled tube is used to exten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com