Ship anchor type anchor head of ground anchor stretching when grouting

A technology of grouting and ship anchoring, which is applied in the direction of earthwork drilling, installation of anchor rods, sheet pile walls, etc., which can solve the problems of limited depth, limited supply of anchoring force, complicated construction technology, etc., and achieve large anchoring force and convenient construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

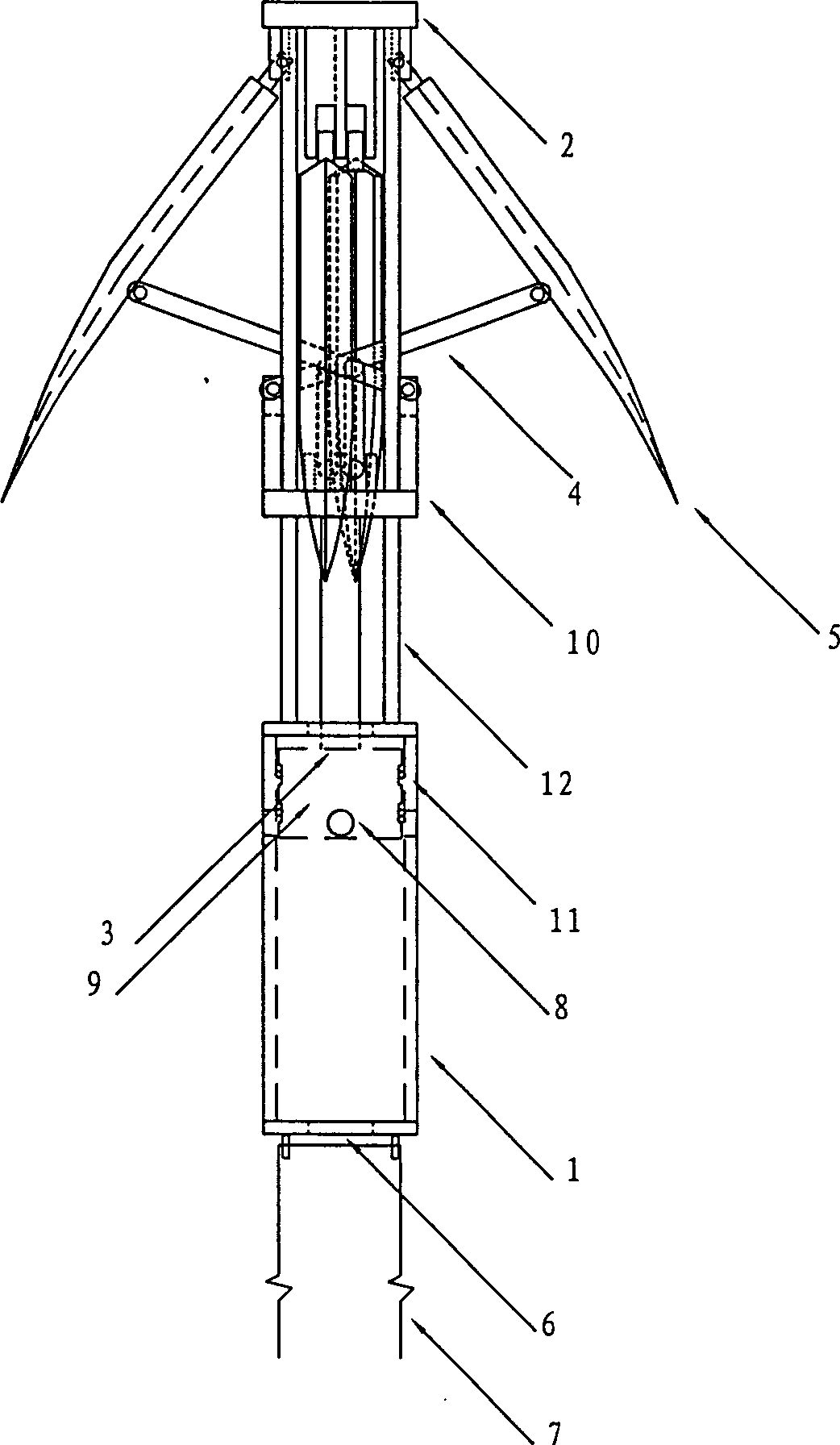

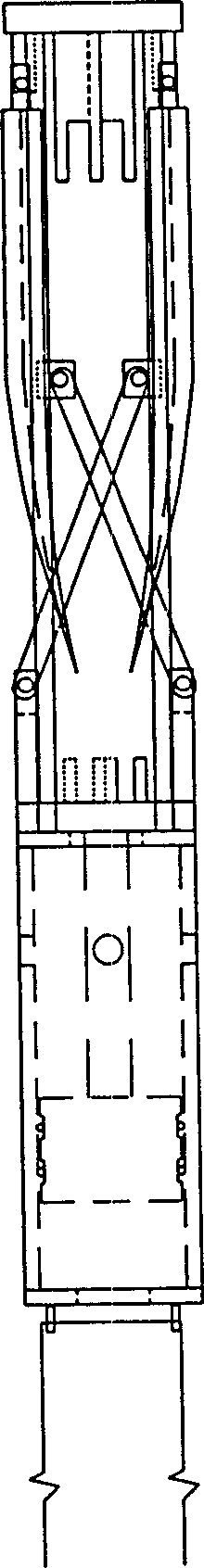

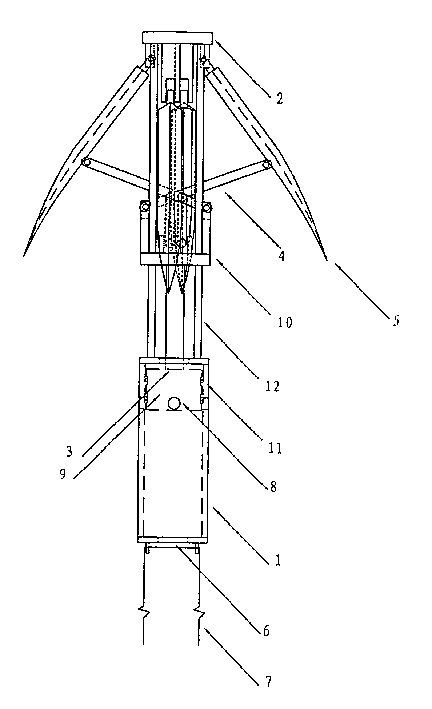

[0010] Such as figure 1 and figure 2 As shown, the present invention mainly comprises: steel pipe 1, anchor grab top seat 2, piston propulsion body 3, strut 4 and anchor grab 5, and its connection mode is: anchor grab top seat 2 and steel pipe 1 are connected by fixed pillar 12, four The two ends of the root strut 4 are respectively connected to the strut base 10 and the anchor grab 5 of the piston propelling body 3 by movable pins. The struts 4 are connected, and the anchor head rear portion is provided with a connecting hole to be connected with the anchor cable 7.

[0011] The tail of the steel pipe 1 is provided with a pressure grouting hole 6, and there are four reserved holes 8 on the upper part of the steel pipe 1. Pressure grouting from the pressure grouting hole 6 makes the anchor grab 5 open, and the slurry continues to enter through the four reserved holes 8. Anchor hole. Anchor grab top seat 2 is provided with four bearings. The piston propelling body 3 is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com