Patents

Literature

32results about How to "Reduce drilling workload" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

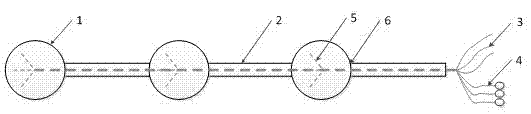

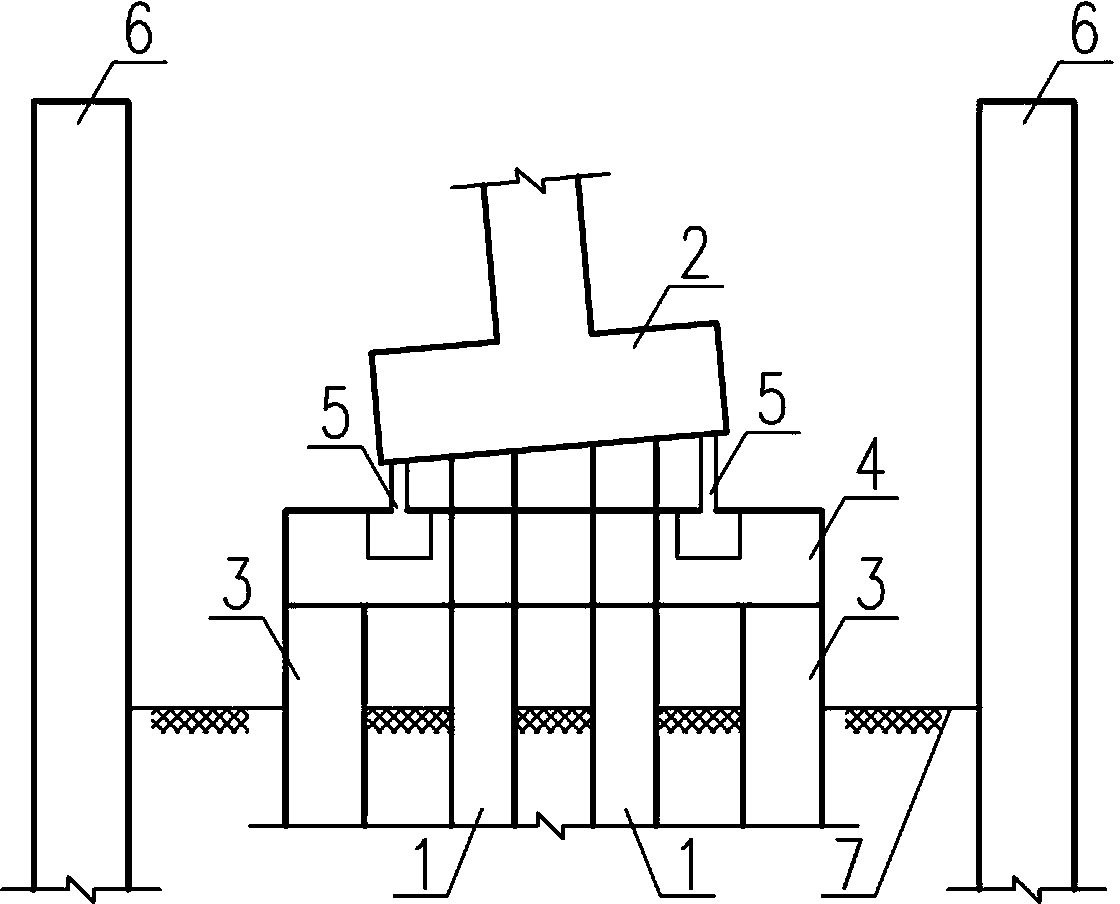

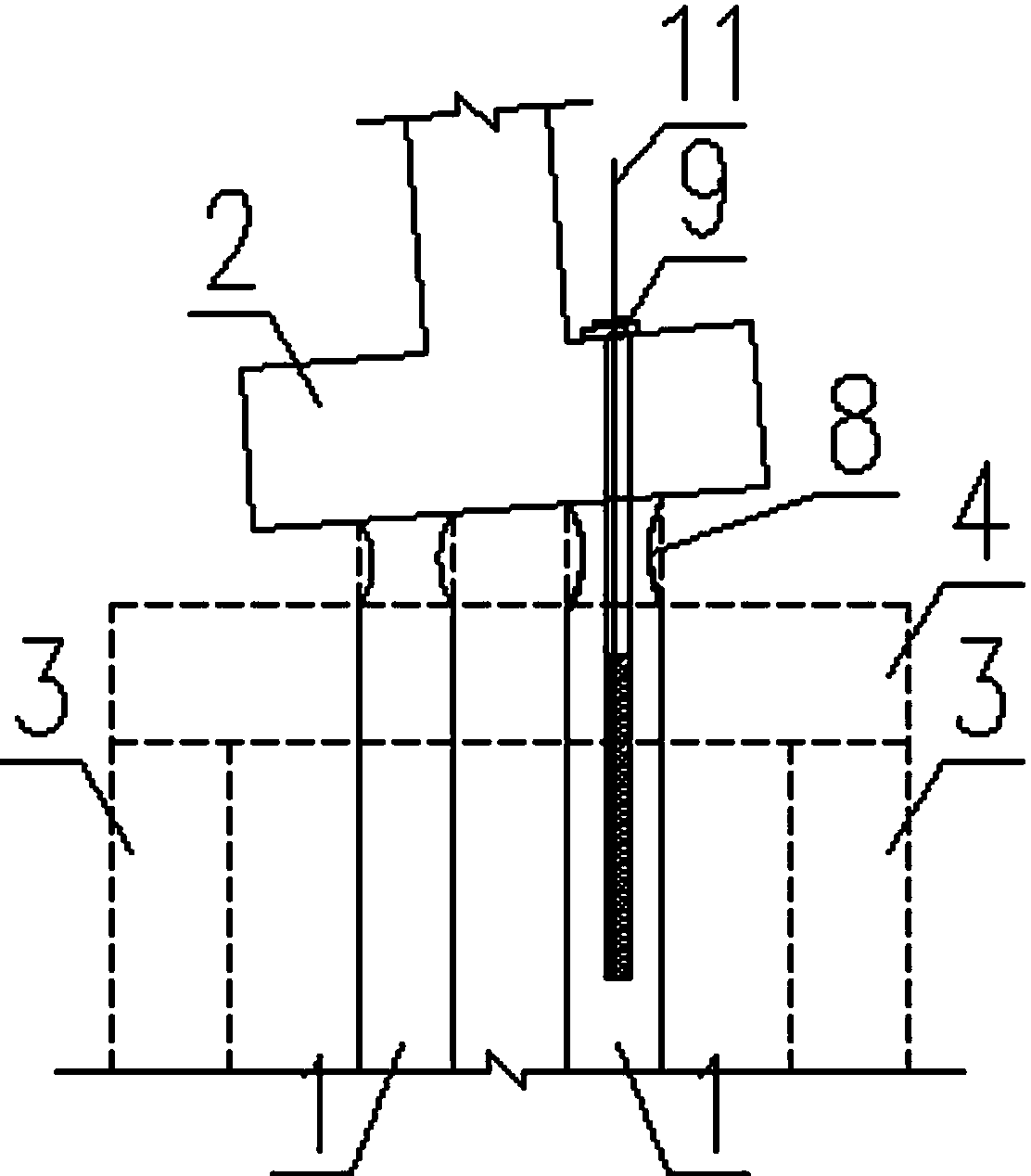

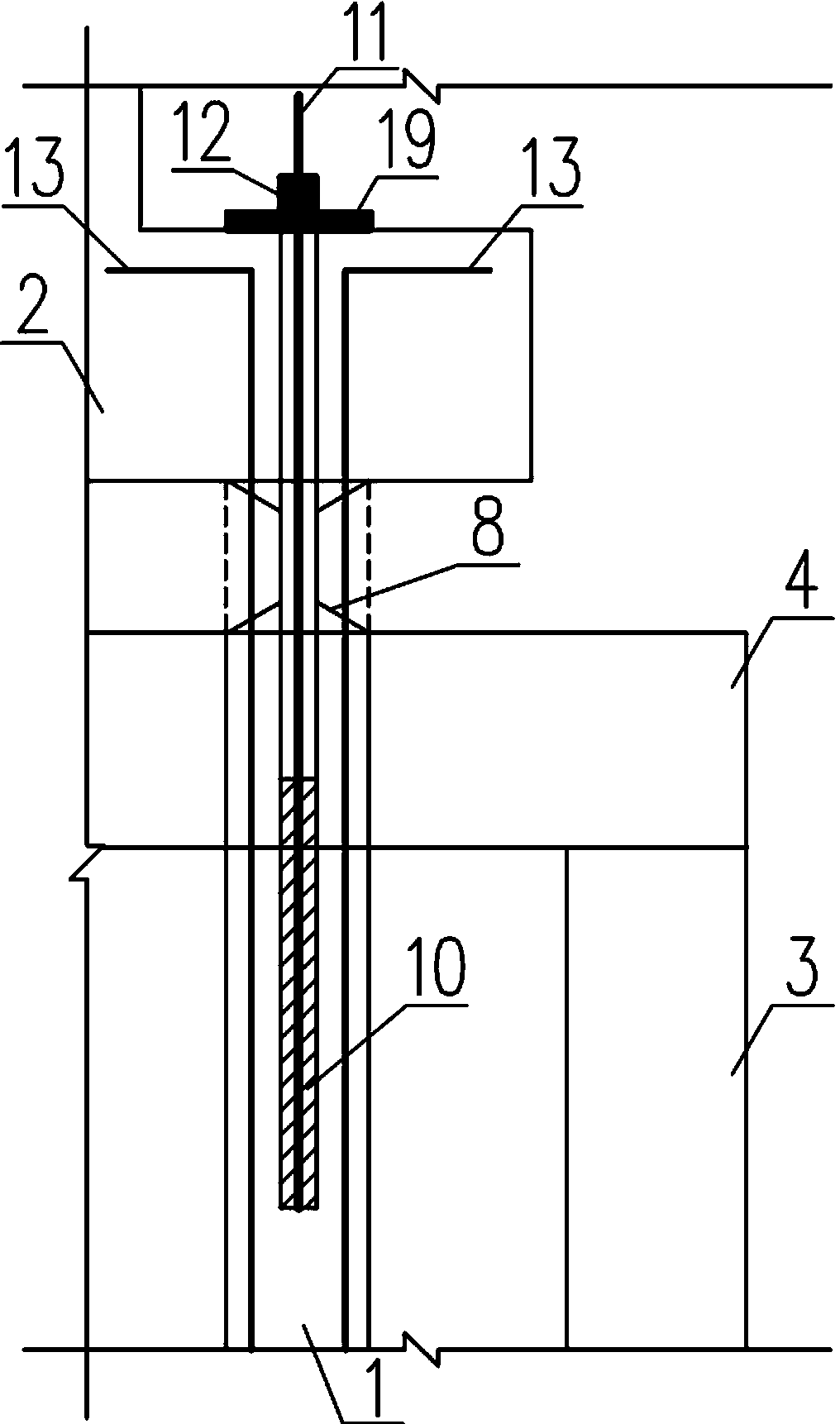

Method for extracting coalbed gases from coal mines by upper and lower combination

The invention relates to coalbed gas mining technology, in particular to a method for extracting coalbed gases from coal mines by upper and lower combination. The method solves the problem of poor gas drainage effects through surface well drilling and hole drilling in the coalbed. The method comprises the following steps: constructing extraction drilled wells on the surface, constructing underground directional long drilled holes in the coalbed, crosslinking the fracture areas of the extraction drilled wells with the drainage areas of the underground directional long drilled holes, then effectively sealing the underground directional long drilled holes in the coalbed, then utilizing fracturing equipment on the surface to fracture the drainage areas drilled on the surface and the drainage areas of the long drilled holes in the coalbed via the extraction drilled wells and finally carrying out extraction. The method has the advantages of improving the extraction rate and efficiency of the coalbed gases and shortening the construction period of the coalbed gas extraction engineering.

Owner:山西蓝焰煤层气集团有限责任公司

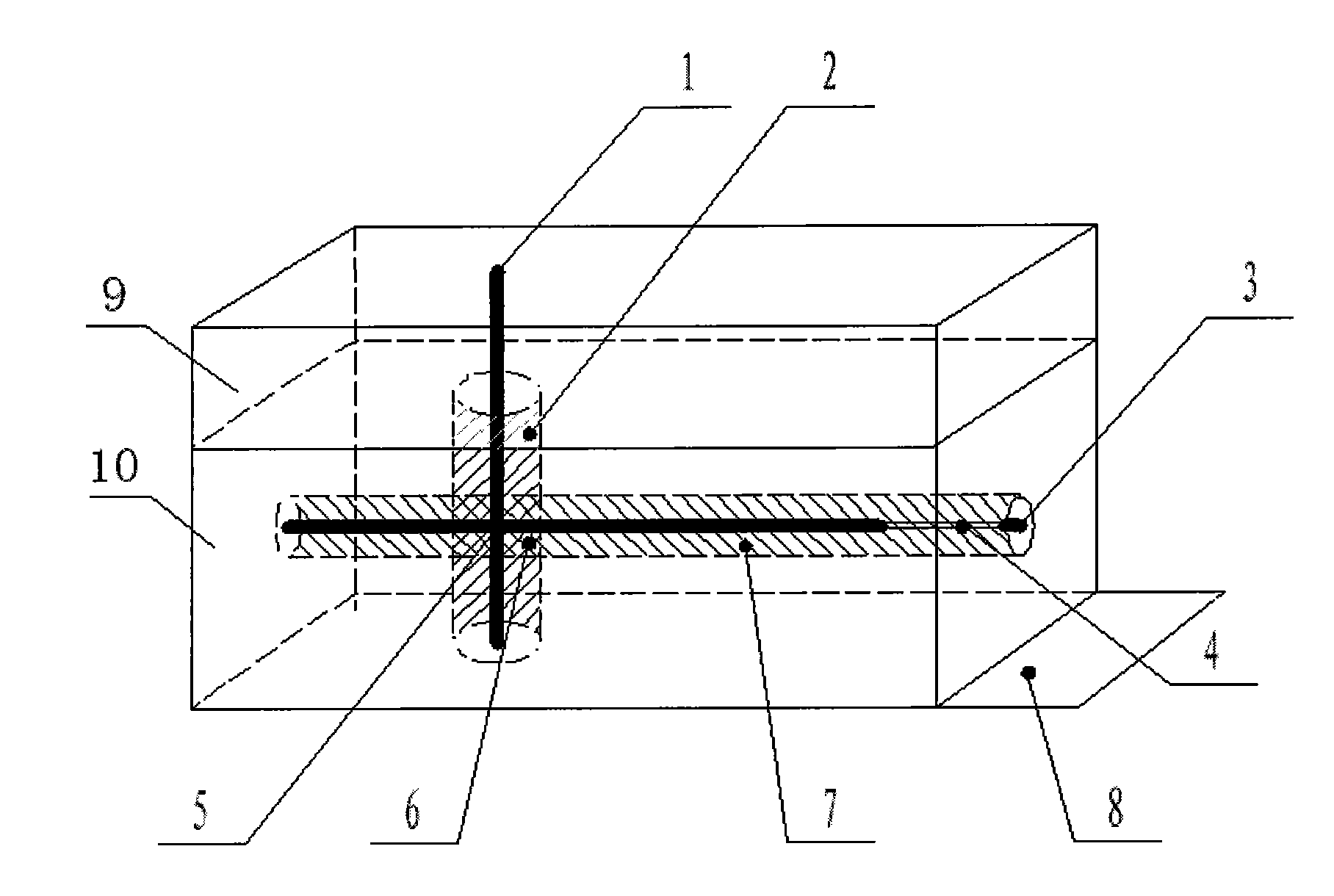

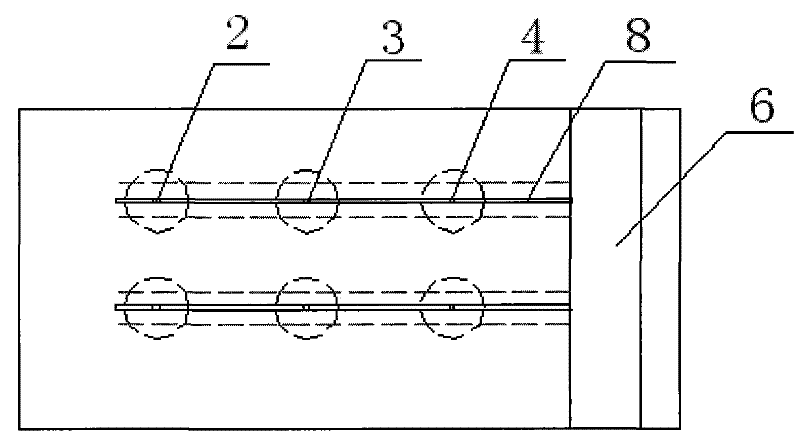

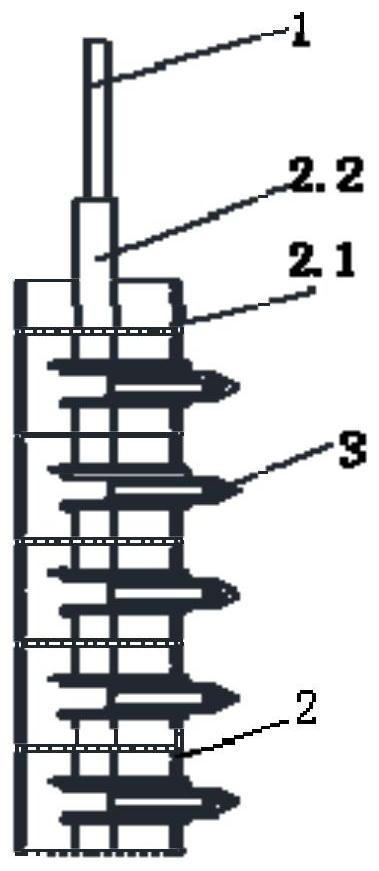

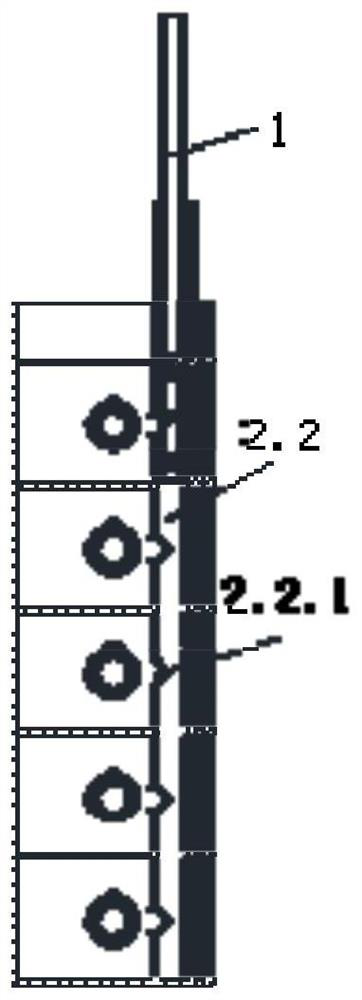

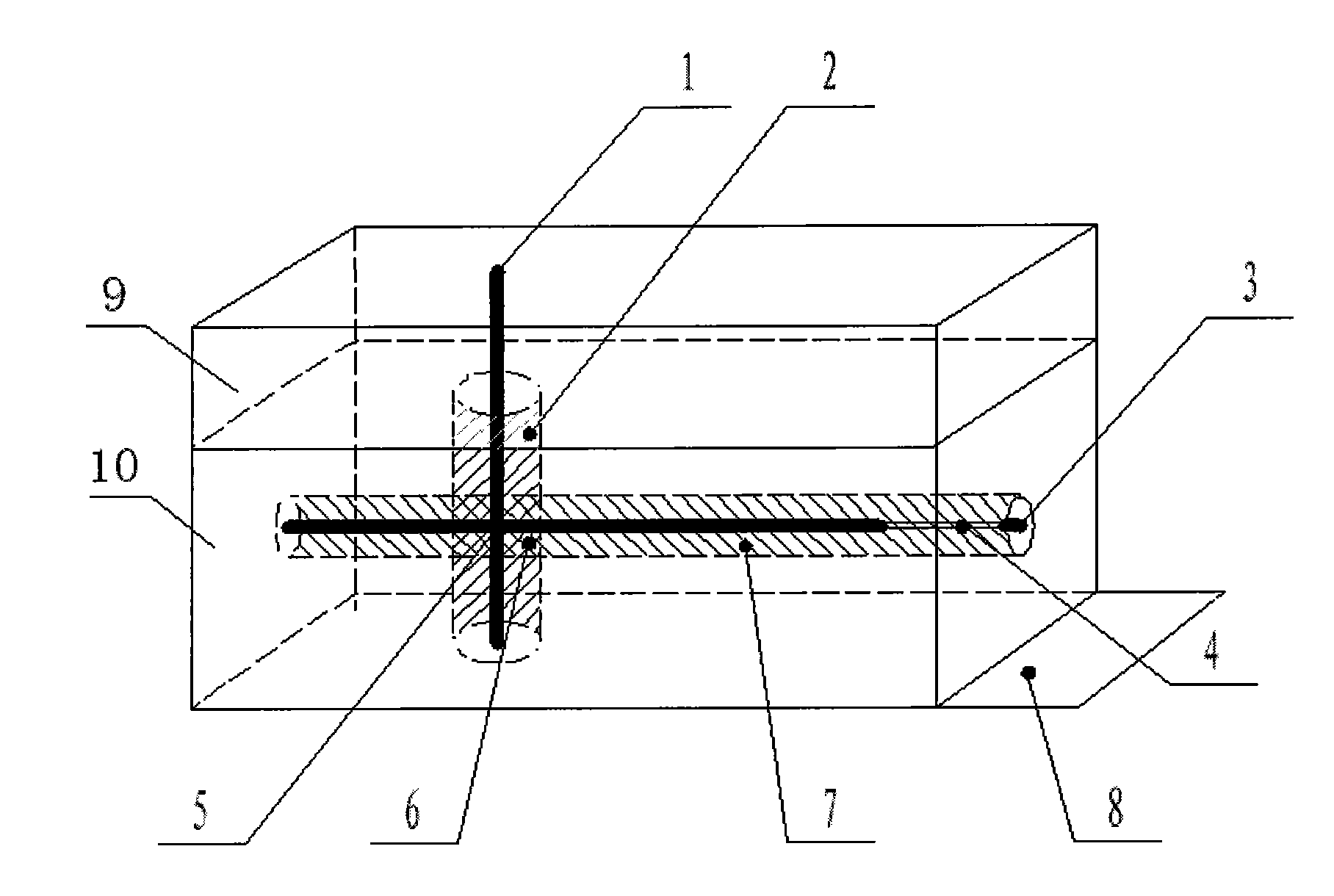

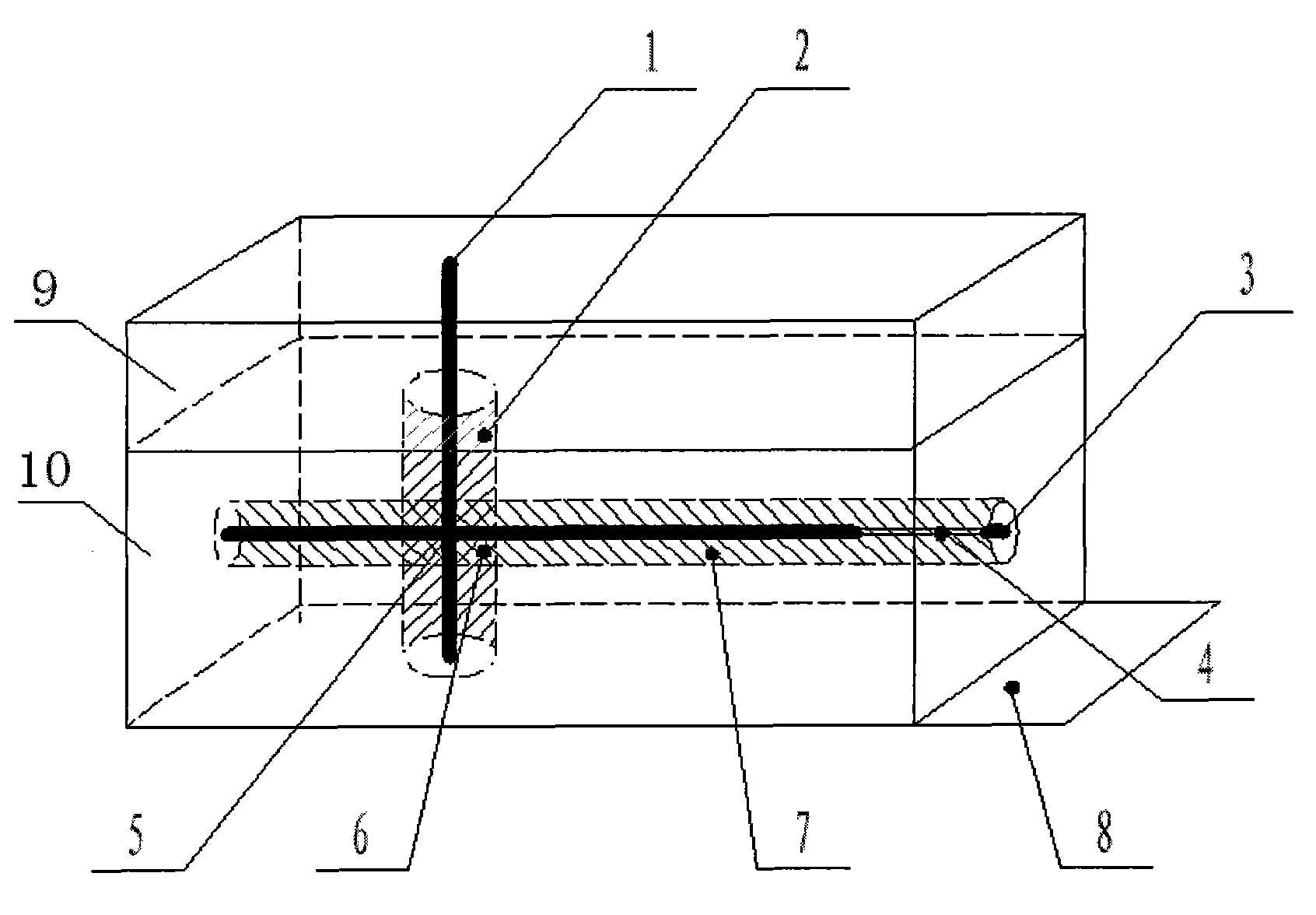

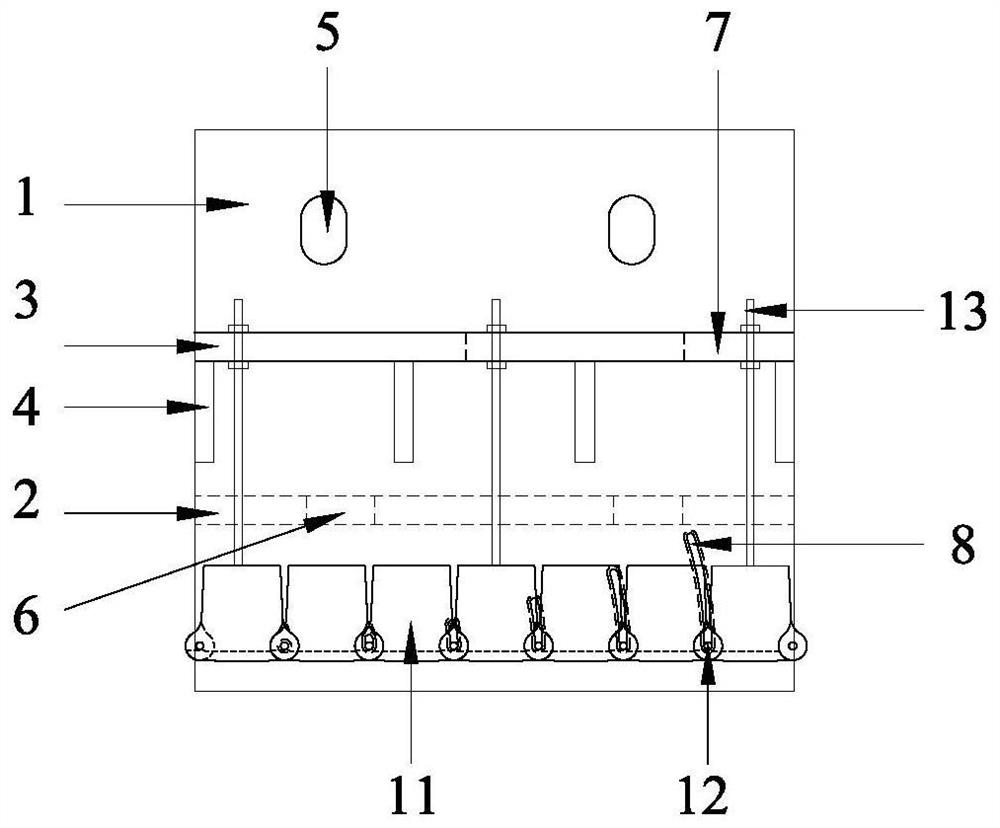

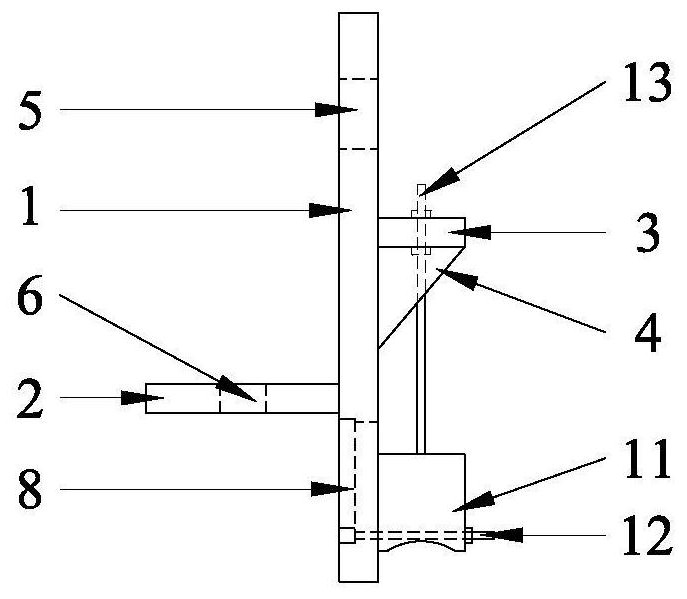

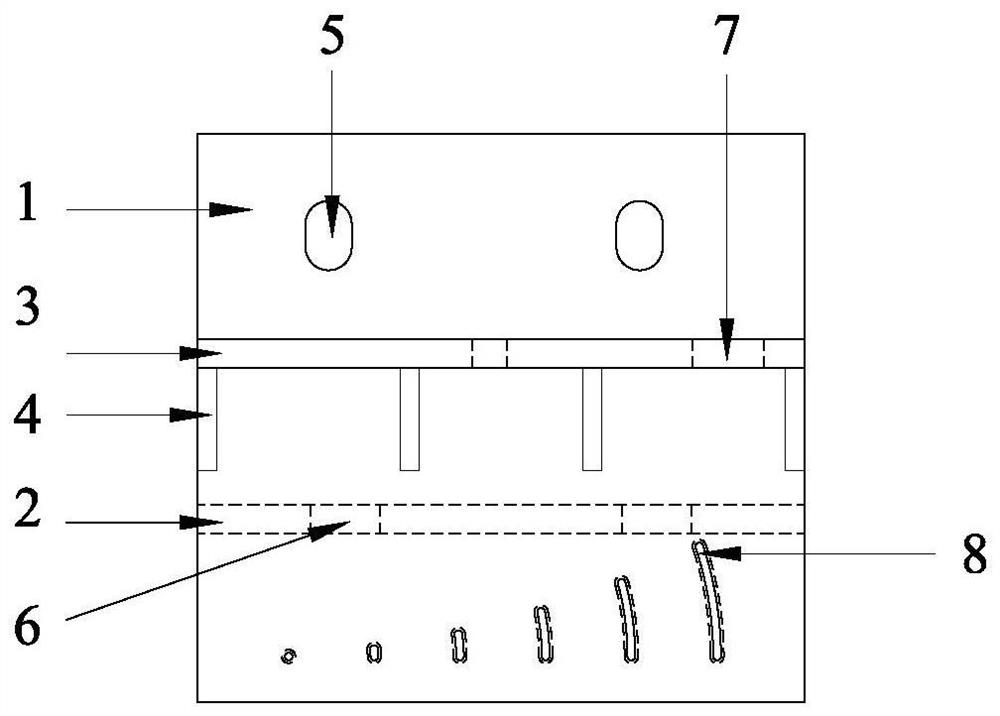

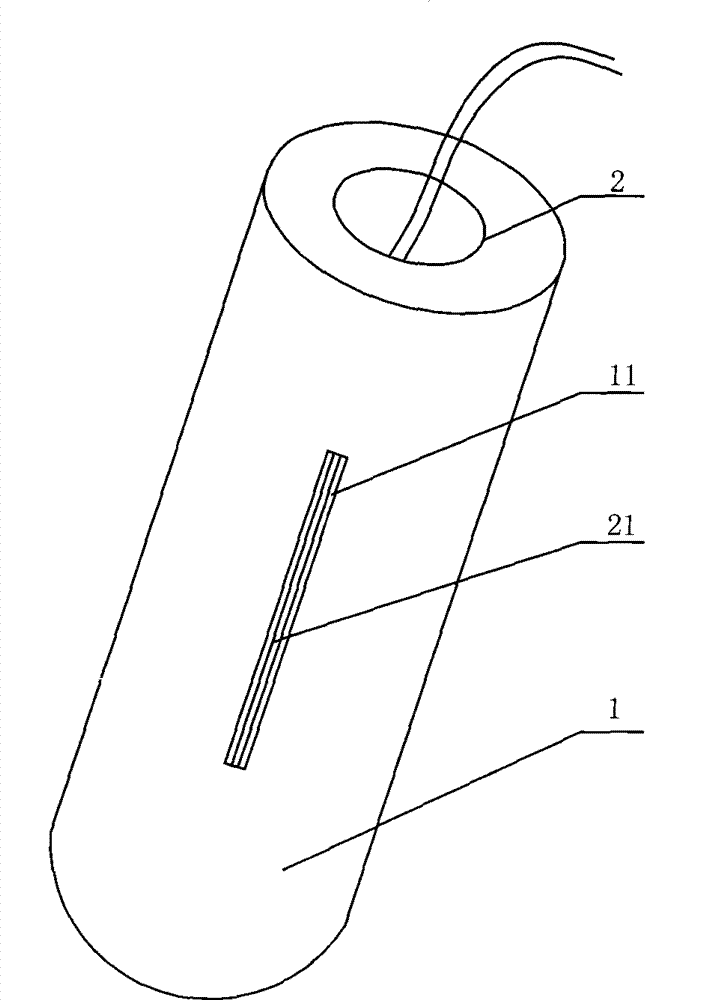

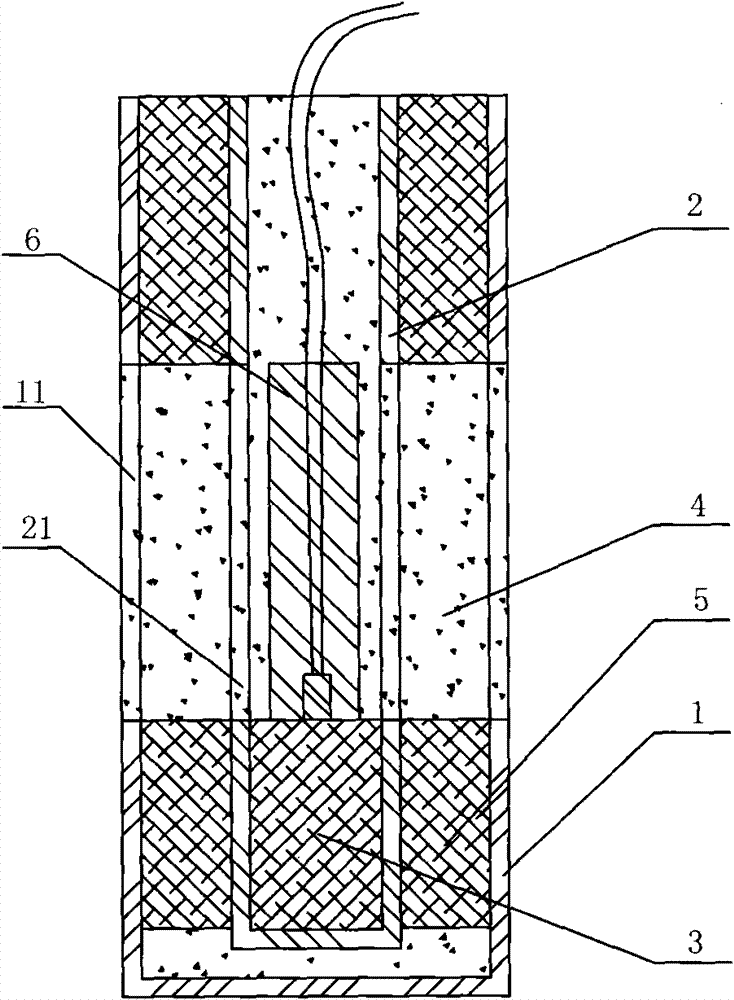

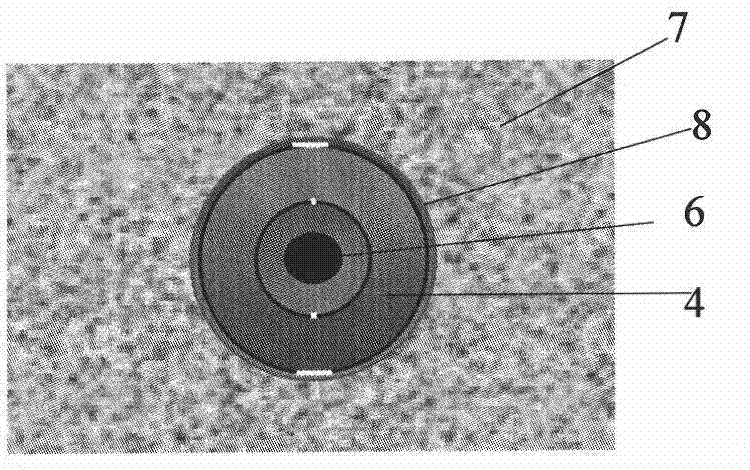

Device and method for integrated collection of stress and displacement of surrounding rocks

InactiveCN102818665ACan measure three-dimensional stressThree-dimensional stress can be calculatedForce measurement by measuring optical property variationUsing optical meansFiberStress measurement

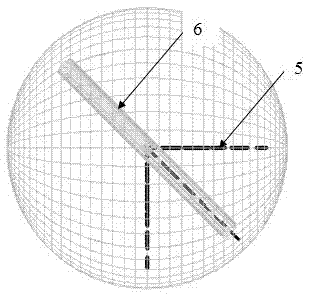

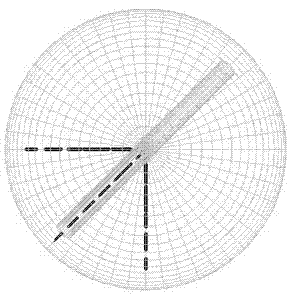

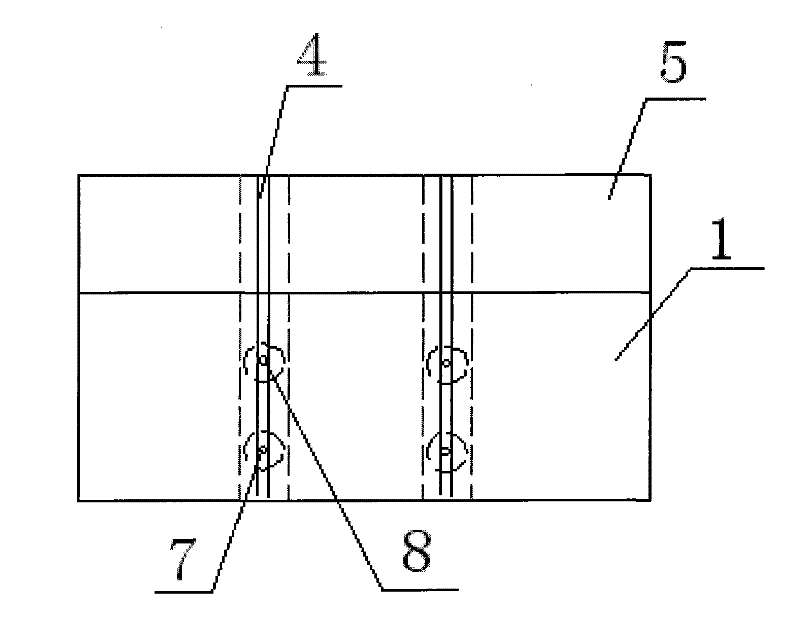

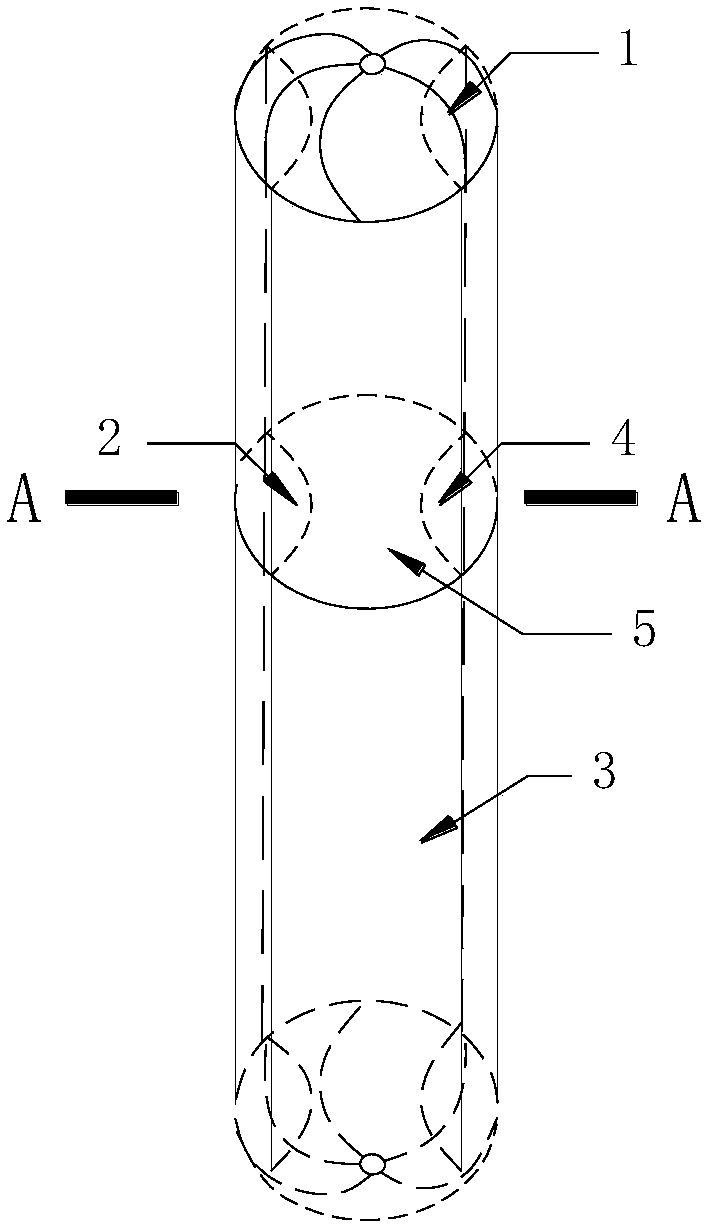

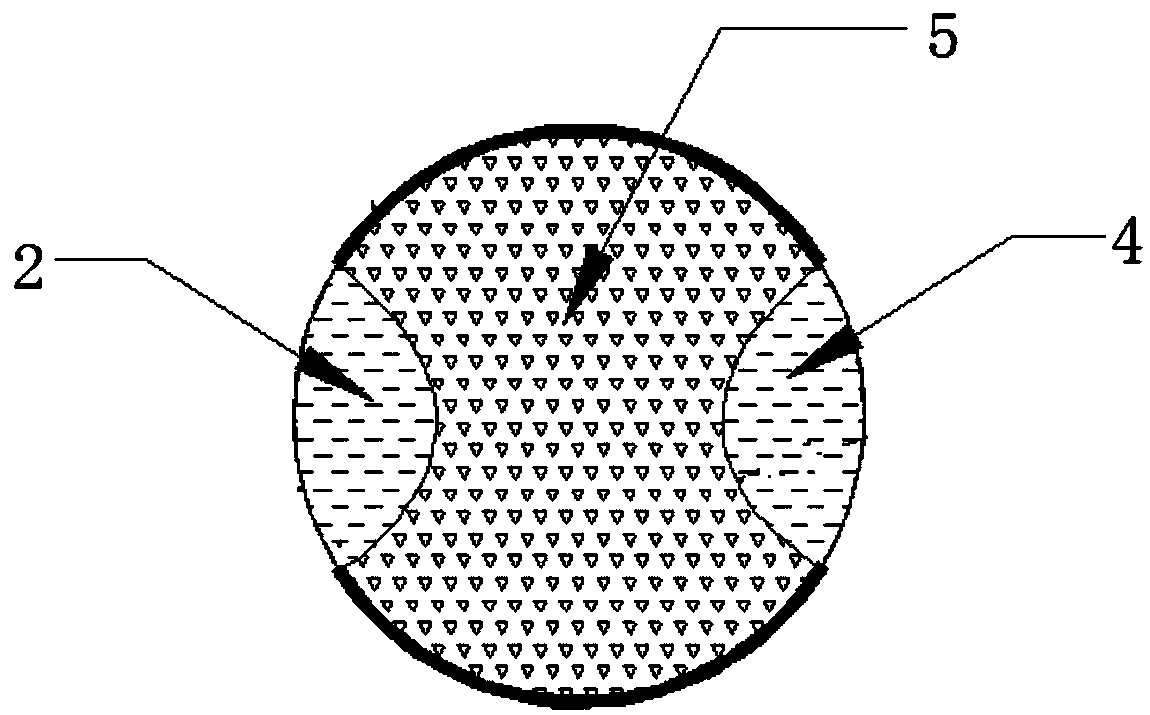

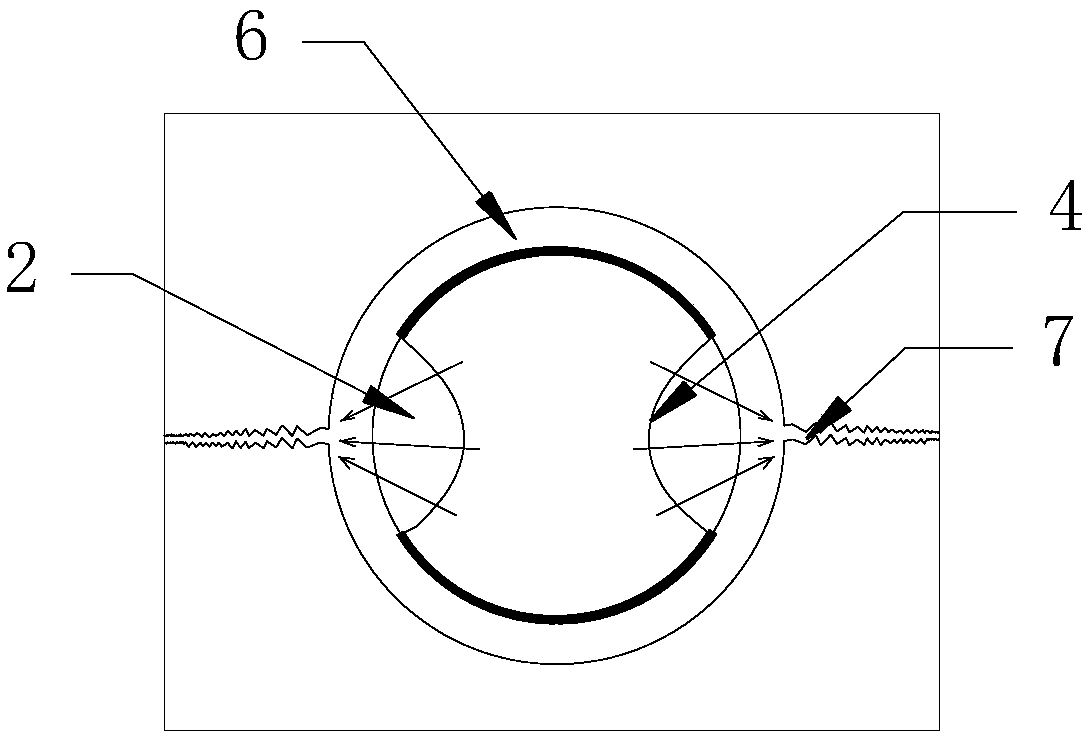

The invention discloses a device for integrated collection of stress and displacement of surrounding rocks, which comprises a spherical body, a casing pipe, a steel wire and an optical cable, wherein a threaded hole is formed by drilling along one diameter of the spherical body; a fiber bragg grating is adhered along six different directions in the spherical body respectively; one end of the steel wire is fixed on the spherical body; and one end of the optical cable is connected with the fiber bragg gratings in the spherical body. According to the device and the method for integrated collection of stress and displacement of surrounding rocks disclosed by the invention, three-dimensional stress of a point can be calculated by measuring stresses in six directions of the point, and stress and displacement can be simultaneously measured in one drill hole, therefore, not only comparison and analysis are convenient, but also accuracy of a test result is ensured as mutual interference among a plurality of near-distance drill holes is avoided, and meanwhile, workloads of the drill holes are decreased; the fiber gratings are not influenced by electromagnetic, humid and corrosive environments, and the spherical body is sufficiently contacted with the surrounding rocks as well as with slurry poured in the holes, so that accuracy and reliability of stress measurement result are guaranteed; furthermore, the spherical body is fixed in surrounding rock holes in a way that slurry is poured into the surrounding rock holes, looseness of the spherical body is avoided, as a result, a wrong displacement test result is prevented.

Owner:CHINA UNIV OF MINING & TECH

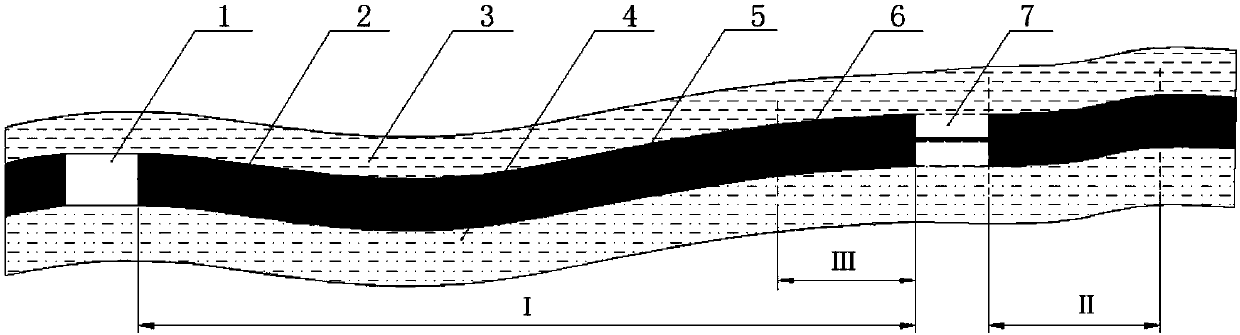

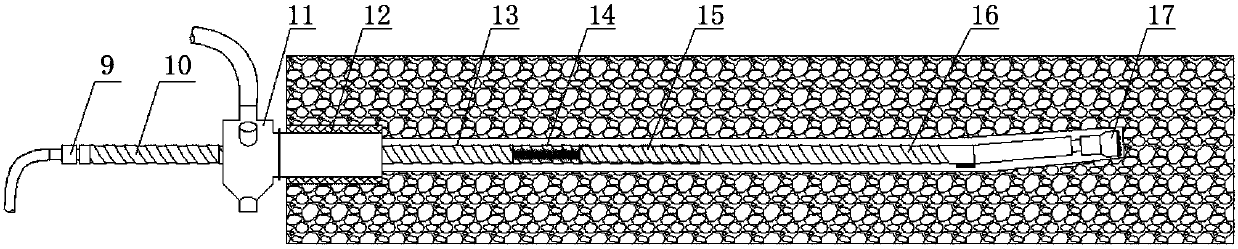

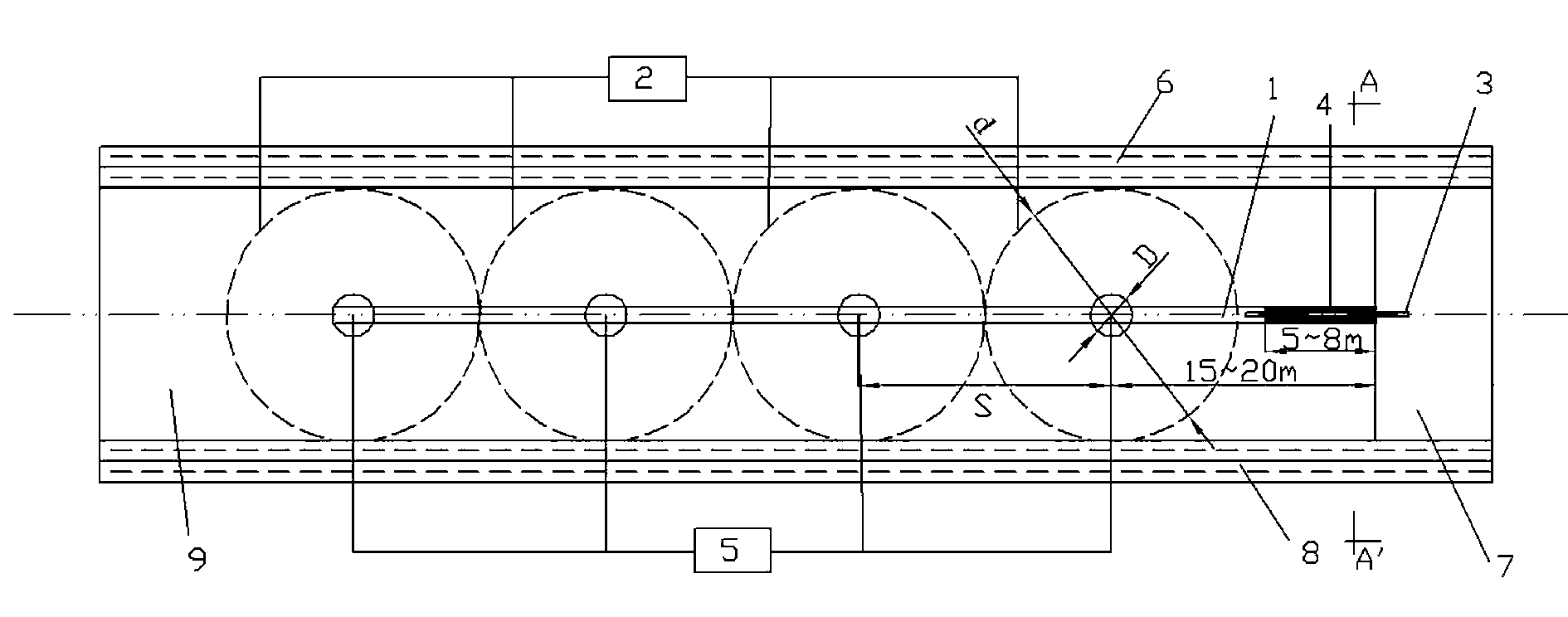

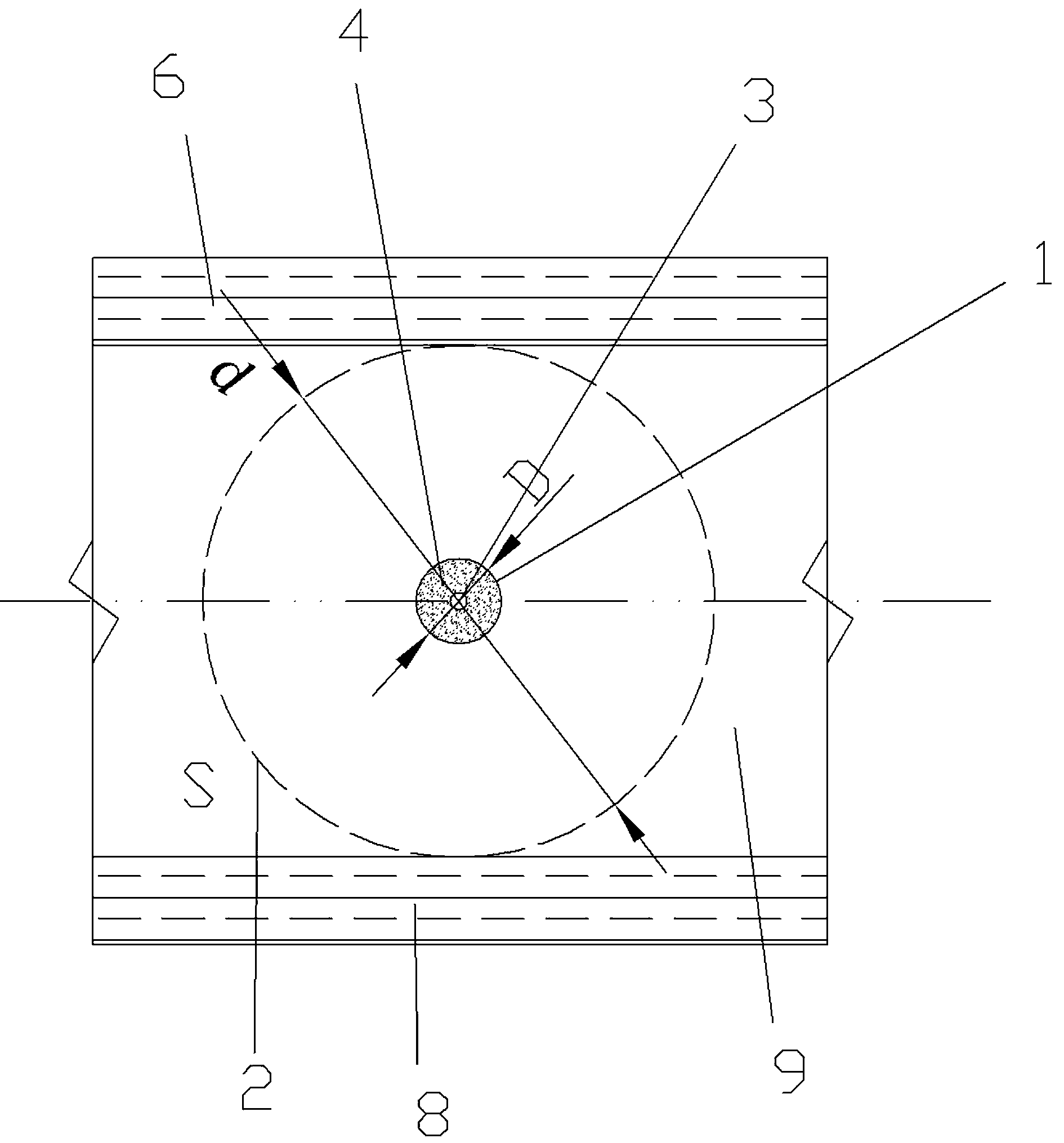

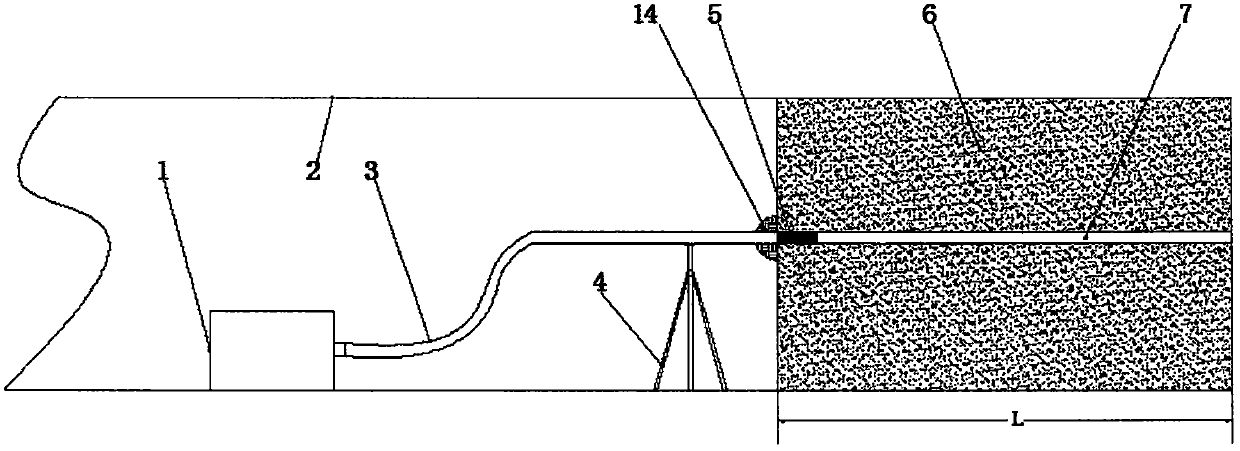

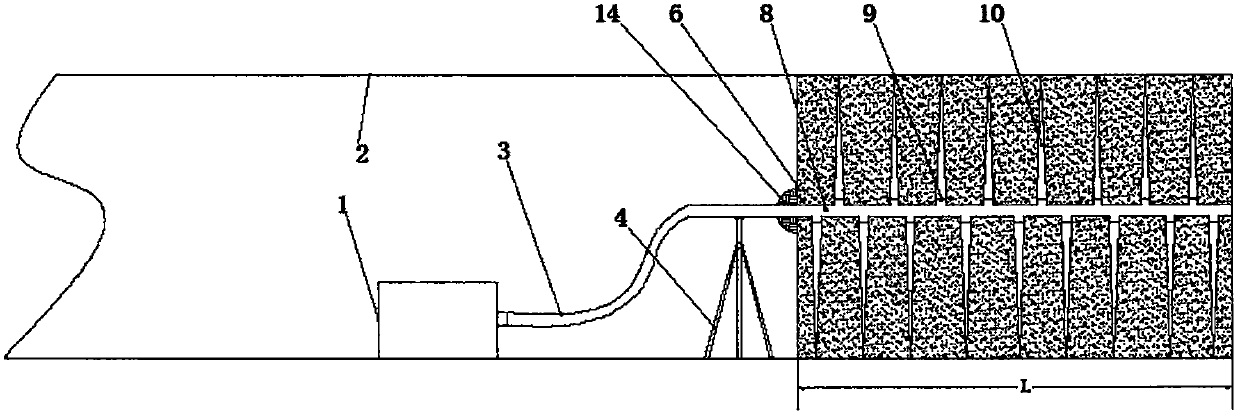

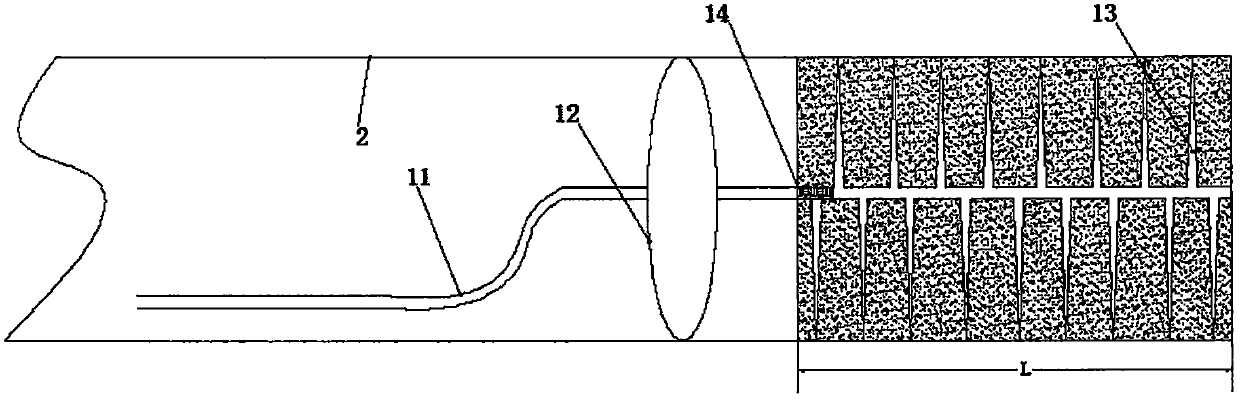

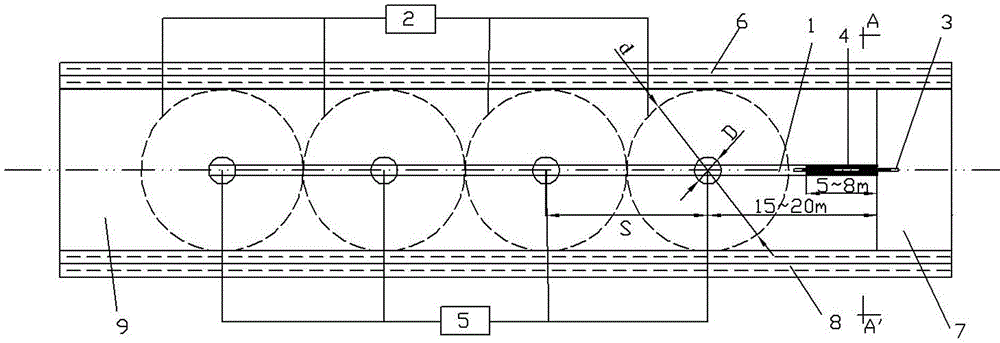

Method for gas extraction through bedding directional long drill hole traversing working face in broken and soft coal seam

InactiveCN107740677AIncreased drilling depthImprove coal seam encounter rateFluid removalDirectional drillingDrill holeSoft Coals

The invention relates to a method for gas extraction through a bedding directional long drill hole traversing working face in a broken and soft coal seam. According to the method, through an air screwmotor directional drilling technology, the bedding gas extraction long drill hole is constructed in a tunneled roadway on one side of the working face of the coal seam, and the drill holes penetratesthrough a to-be-tunneled roadway on the other side of the working face to the position, within the control range of 15-20 m, of the outer side of the roadway; and after the drill hole is completed, adrill tool is lifted up, an open-close type guiding drill bit and a drill rod with a large through hole are put down, then a hole protection screen pipe is put down through the center of the drill rod, then the drill rod is lifted up, the screen pipe stays in the hole, and then a gas extraction pipeline is connected for gas pre-extraction. An air screw motor directional drilling method is adoptedin the gas treatment technology so that the drilling depth of bedding extraction of the broken and soft coal seam and the coal seam drilling-encounter rate can be greatly increased, invalid footagesare reduced in quantity, meanwhile the drill hole coverage range is ensured, the purpose of gas pre-extraction outburst elimination of the stope face and the to-be-tunneled roadway is achieved, and safe tunneling of the coal seam roadway and safe extraction of coal extraction work face are ensured.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP +1

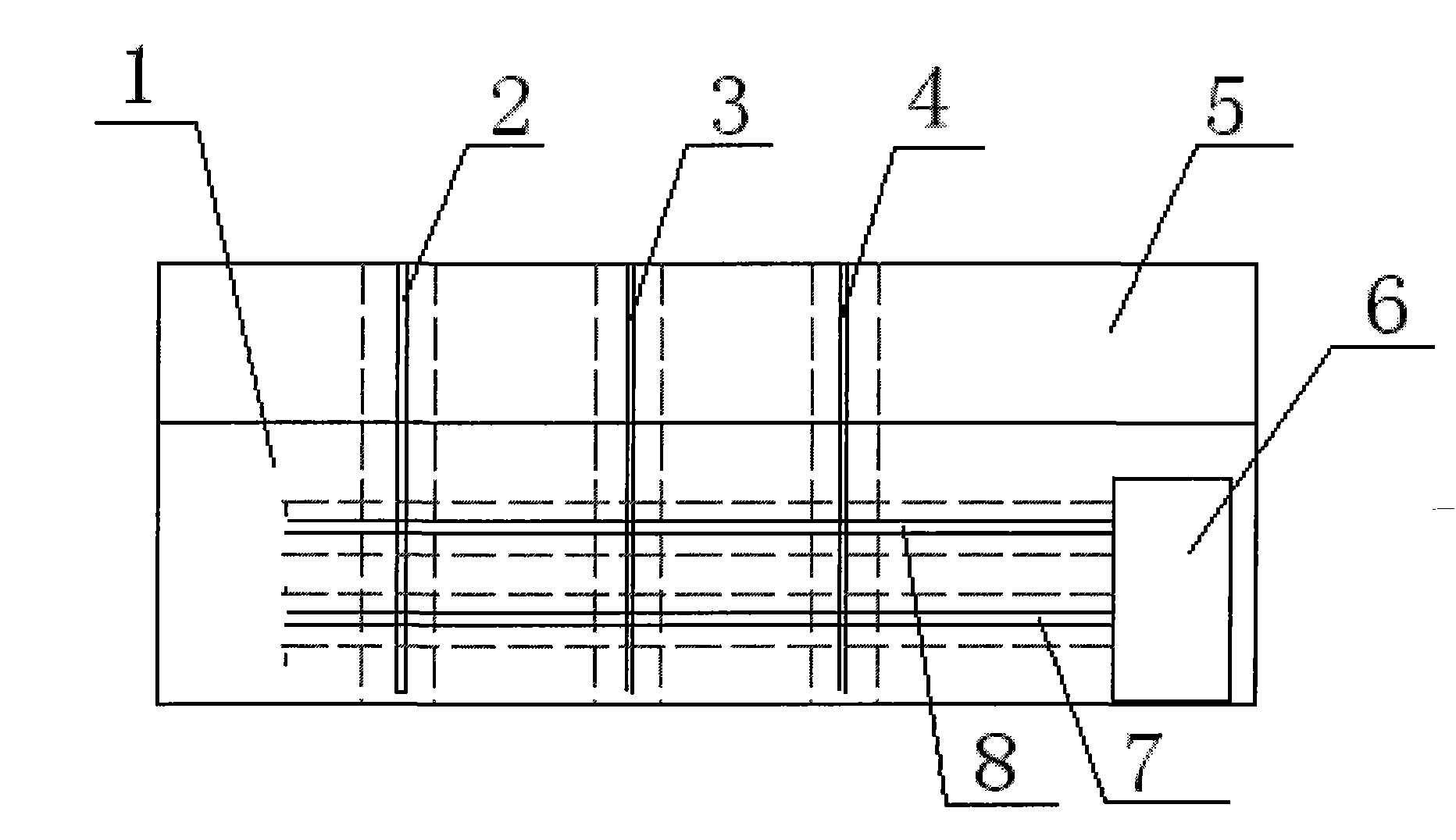

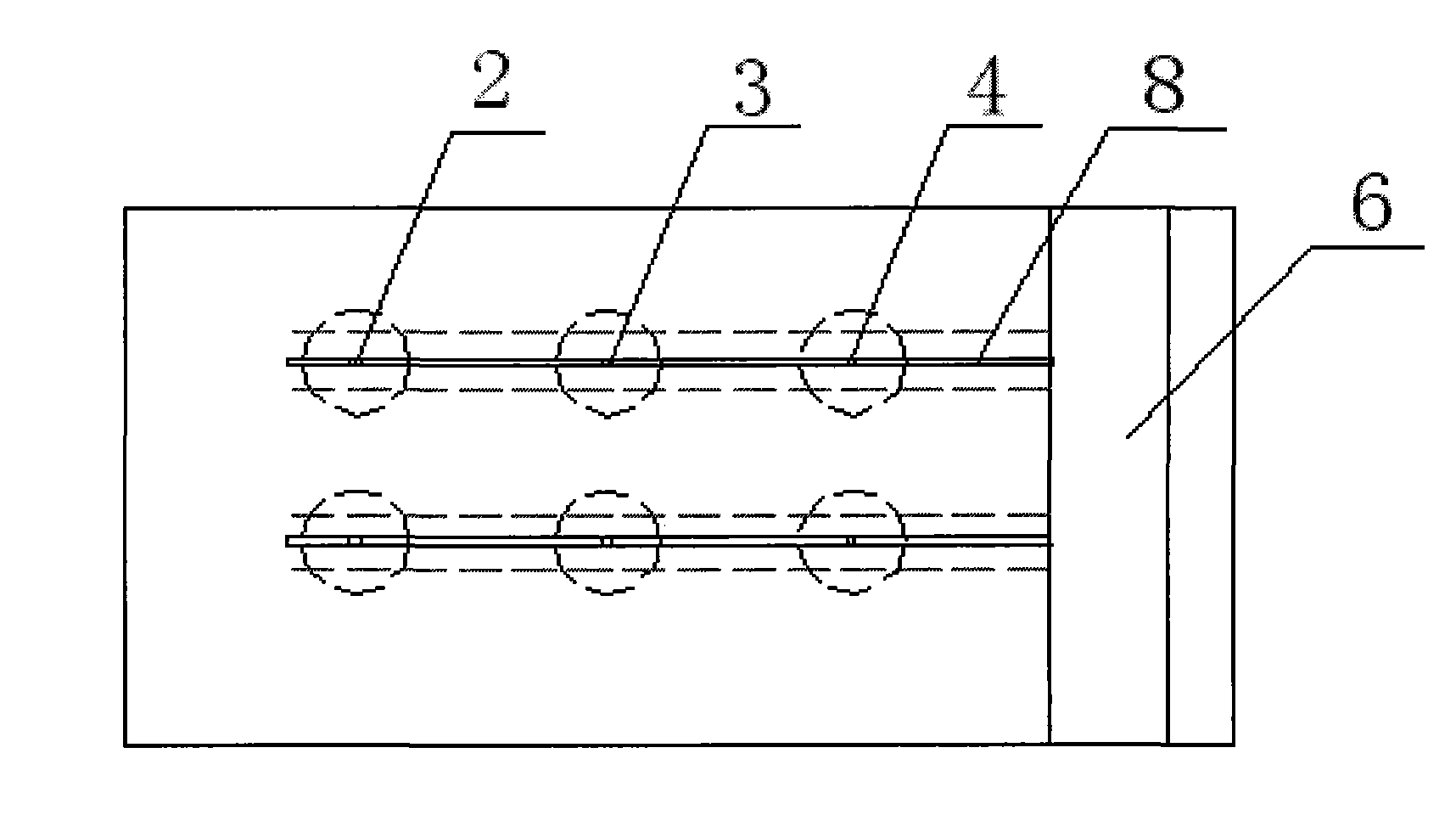

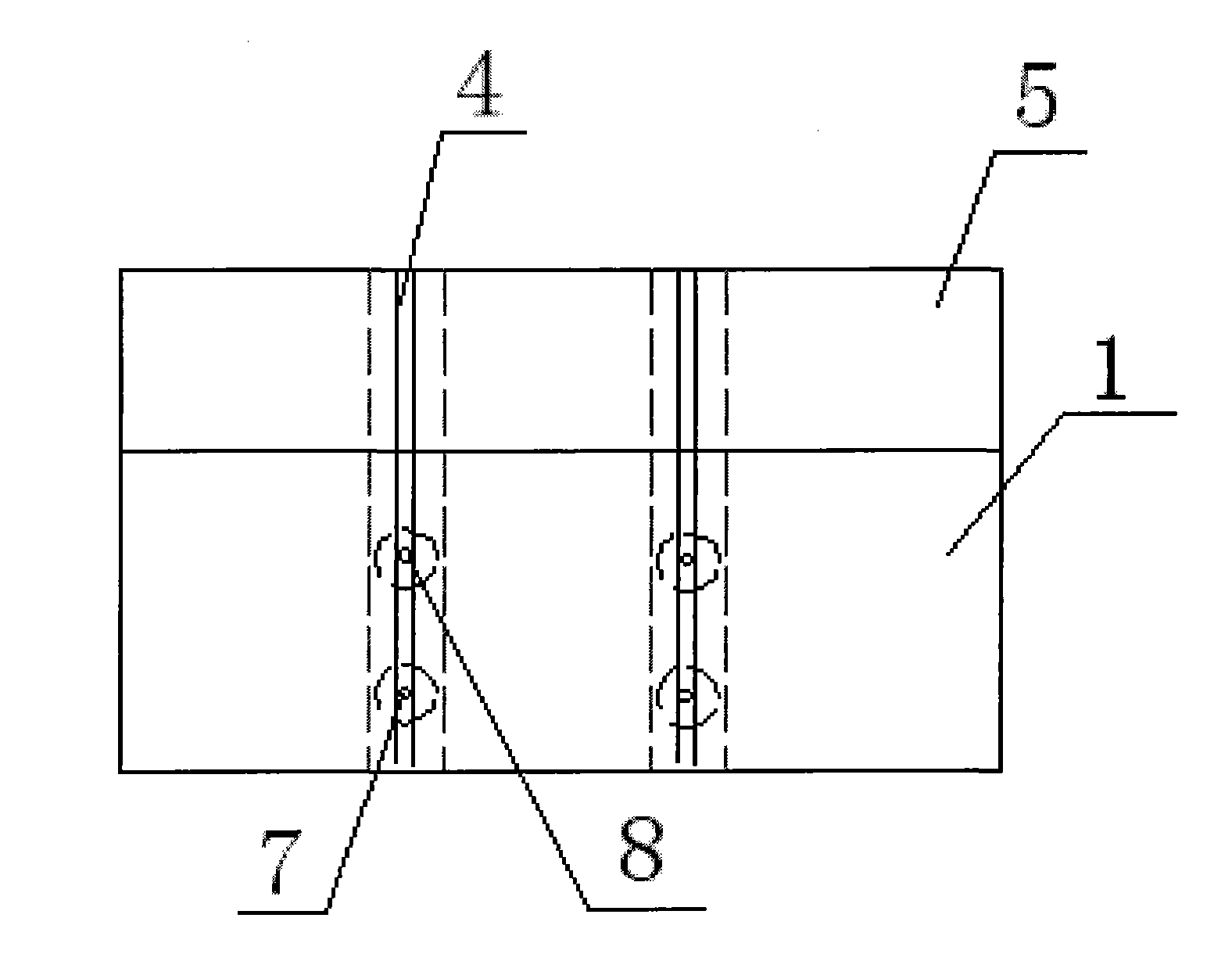

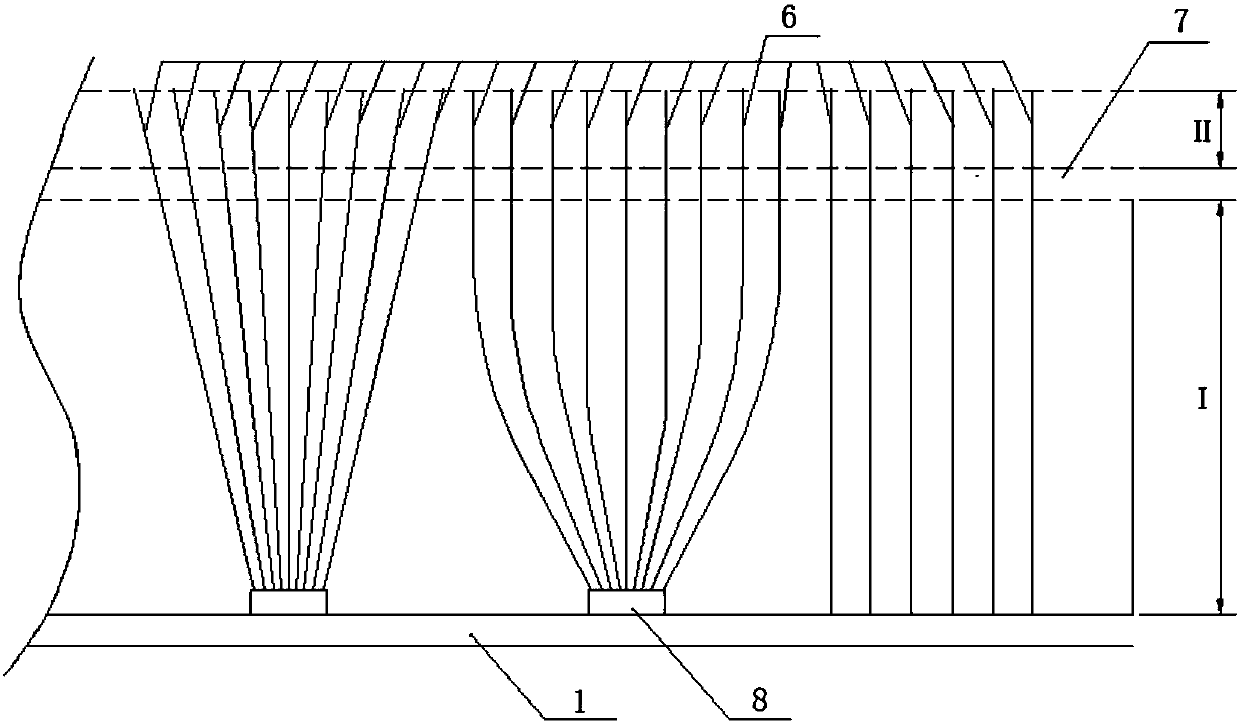

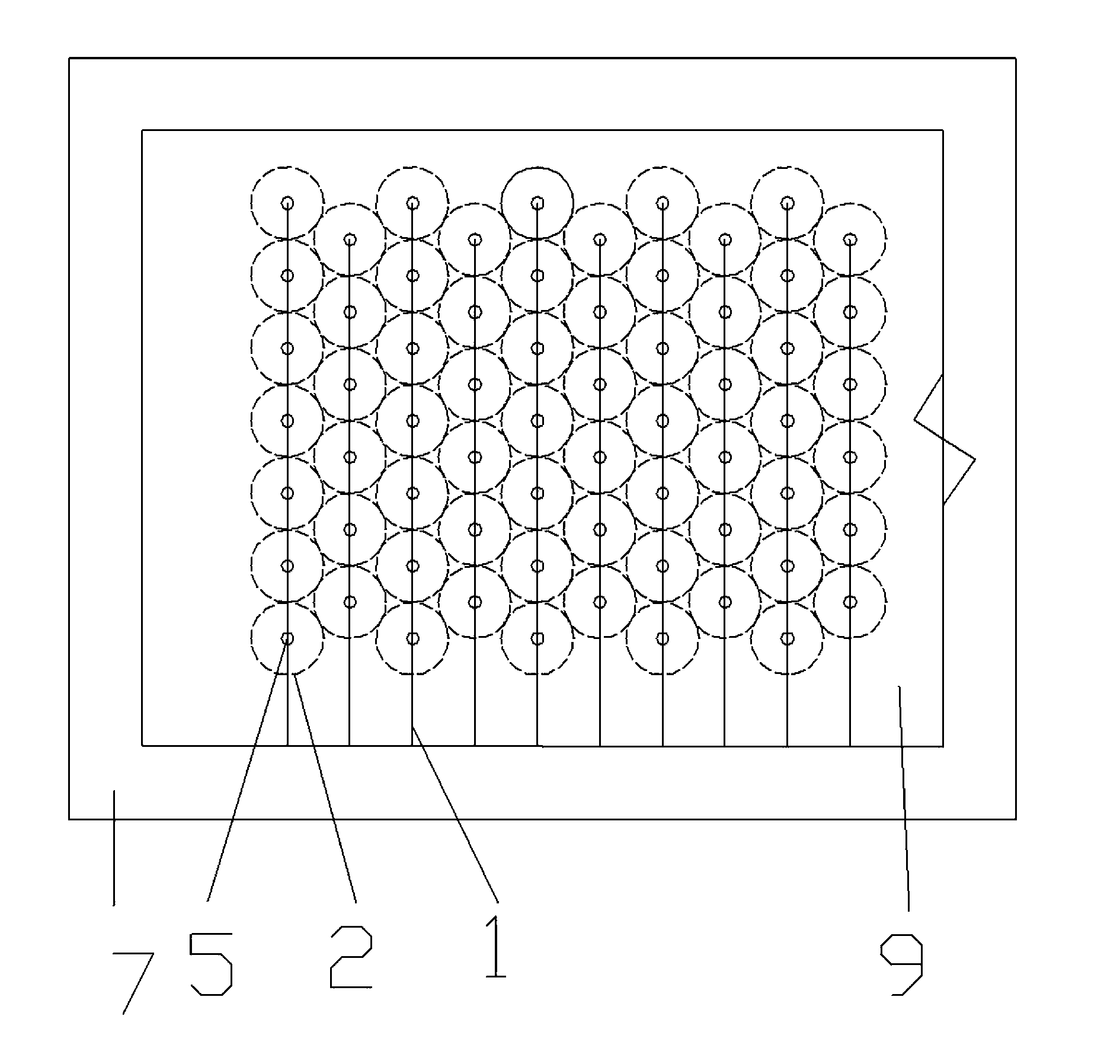

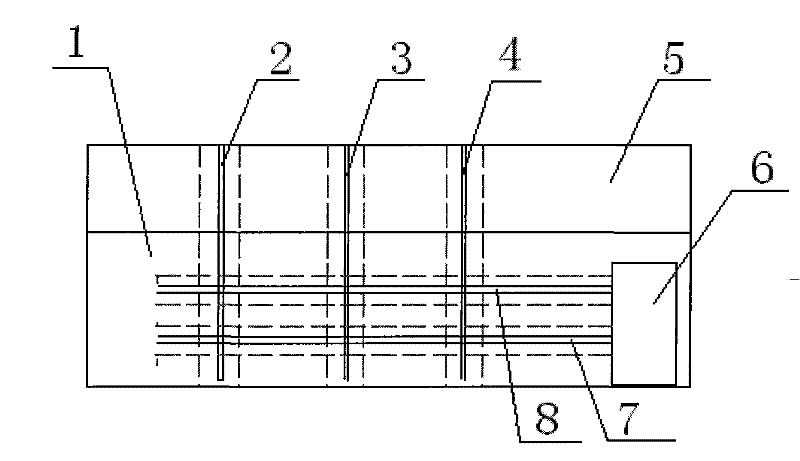

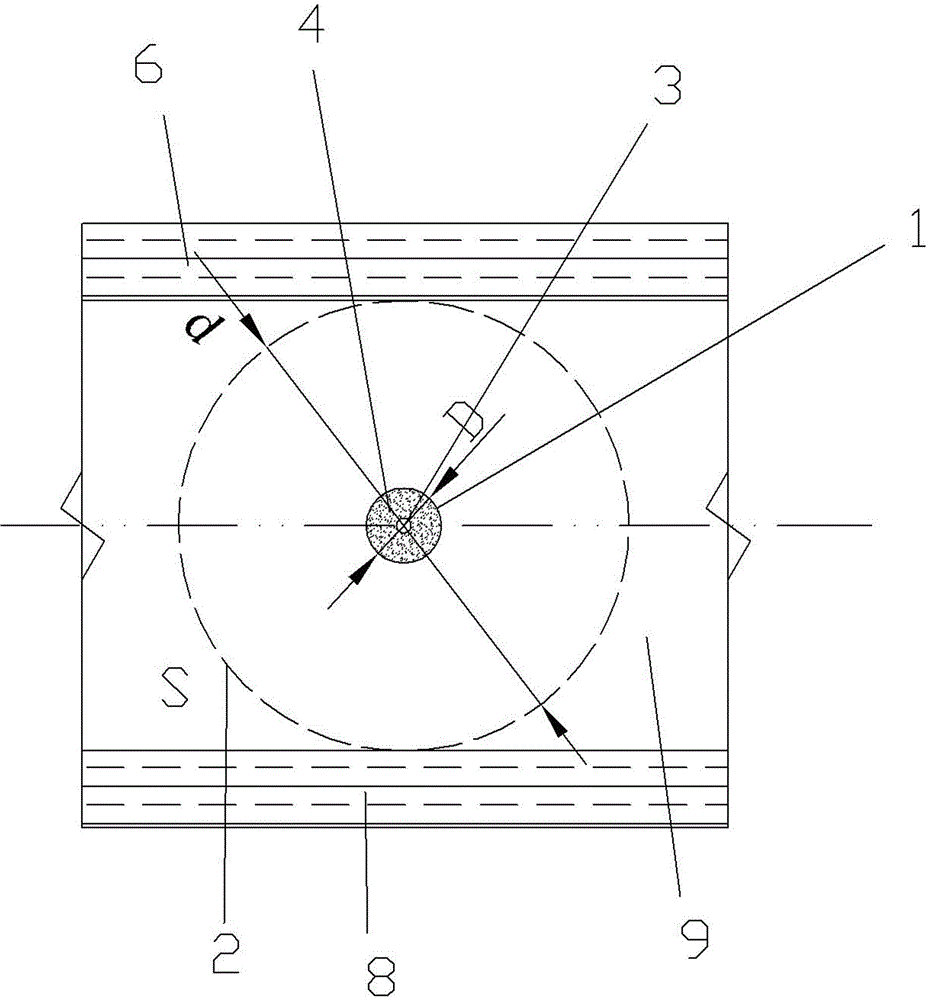

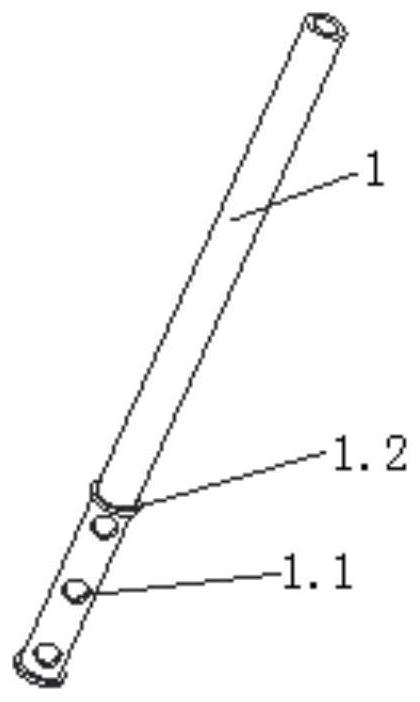

Method for extracting coal bed methane through down-hole bedding long borehole consecutive cave building

ActiveCN103061798AImprove drilling single-hole drainage production capacityImprove extraction efficiencyDrill bitsGas removalDrill siteCoal

The invention relates to a method for extracting coal bed methane through down-hole bedding long borehole consecutive cave building and a hydraulic mechanical drill with the diameter changed and enlarged while drilling. A coal bed bedding long borehole is combined with a cave building technology, and the permeability of low-permeable coal reservoirs and the coal bed borehole extraction capacity are improved. A hole is opened at 1 / 3 coal thickness or 1.5m upwards away from the coal heading floor on the extracting drill site coal wall of an underground coal mine along with the coal bed, the hydraulic mechanical drill with the diameter changed and enlarged while drilling performs cave building on the borehole from inside to outside successively after the borehole reaches the preset depth, and the cave diameters and distances can be calculated through formulas. Coal bed stresses around the cave are released and coal bed prior cracks are widened and lengthened after the caves are completed, tensional and shear failures occur to the coal bed, novel cracks are produced, and accordingly, the coal bed crack connectivity is increased, the permeability is improved, the coal bed methane can be depressurized and desorbed rapidly, the coal bed methane extracting efficiency is improved dramatically, and the coal bed methane extracting time is shortened.

Owner:ZHONGBEI UNIV +1

Self-balance anchor counter weight broken pile forced landing rectification method

The invention discloses a self-balance anchor counter weight broken pile forced landing rectification method. The self-balance anchor counter weight broken pile forced landing rectification method comprises the following steps of: drilling an anchor rod hole in a foundation pile planned to be truncated; taking the position planned to be truncated as a boundary; taking a lower-part pile body as an anchoring section, an upper-part anchor hole as a free section and a bearing platform which needs to be rectified as an outer anchor bed to form a self-balance anchor; cooperating with various traditional direct broken pile technologies, or artificially arranging a base pile section weakening section on a pile end; buckling the pile body concrete of the section weakening section under the joint action of the upper-part load self weight and the self-balance anchor counter weight to realize the broke pile; realizing the counter weight broken pile forced landing rectification; rectifying building and structure inclination caused by the uneven sedimentation of the pile foundation. According to the self-balance anchor counter weight broken pile forced landing rectification method disclosed by the invention, the self-balance anchor used for assisting the counter weight directly adopts the lower-part pile body of the foundation pile as the anchor rod anchoring section to provide anchoring counter force, the counter weight problem of broken pile forced landing is solved by the ingenious economic means, and therefore the broken pile forced landing can be safer and controllable. According to the self-balance anchor counter weight broken pile forced landing rectification method disclosed by the invention, change and disturbance on the stressed system and the foundation of the building and the structure can be avoided, and the building and the structure can be more safely used after being rectified.

Owner:WUHAN SURVEYING GEOTECHN RES INST OF MCC

Process for pumping and exploiting coal bed gas by together using ground well drilling and underground hole drilling

The invention relates to a coal bed gas exploiting technique, in particular to a process for pumping and exploiting coal bed gas by together using ground well drilling and underground hole drilling, solving the problem of low efficiency of the traditional method for pumping and exploiting the coal bed gas. The process comprises the following steps of: (1) carrying out well drilling on the ground; (2) carrying out long hole drilling in underground coal beds; (3) making drilled holes and ground drilled wells crosslink and communicate in the appointed points by utilizing an orientation technique of a long hole drilling machine; (4) effectively closing the underground long drilled holes; (5) fracturing the ground drilled wells and the underground long drilled holes by utilizing fracturing equipment on the ground; (6) after fracturing, closing the ground drilled wells; and (7) opening the closed ends of the underground long drilled holes and then installing relevant pumping and discharging pipelines connected with underground pumping and discharging systems. The process improves the pumping and exploiting speed and efficiency of the coal bed gas, shortens the construction period of coal bed gas pumping and exploiting engineering and saves the construction investment of the coal bed gas pumping and exploiting engineering.

Owner:山西蓝焰煤层气集团有限责任公司

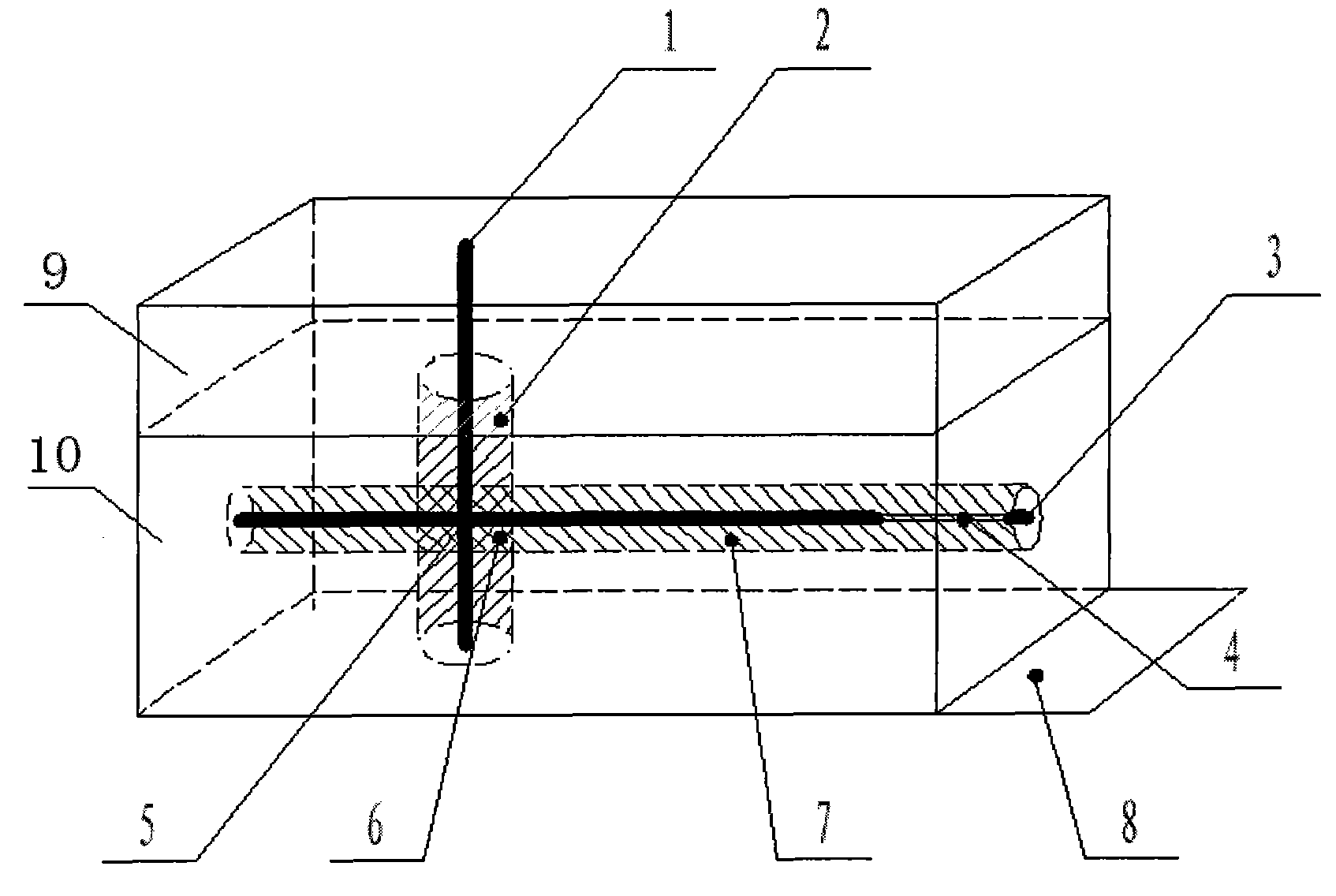

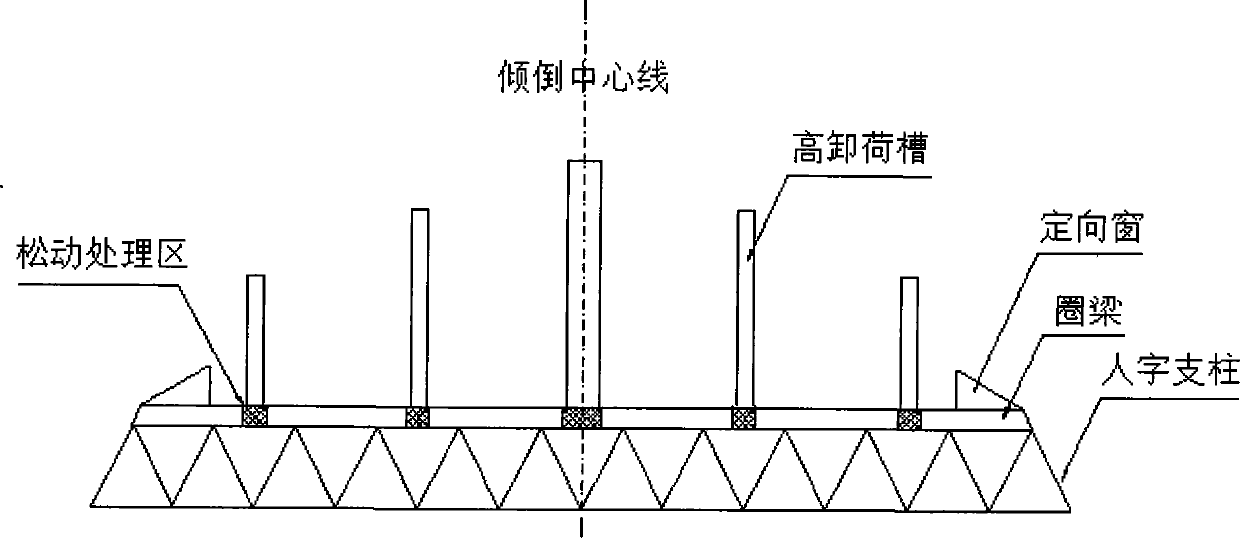

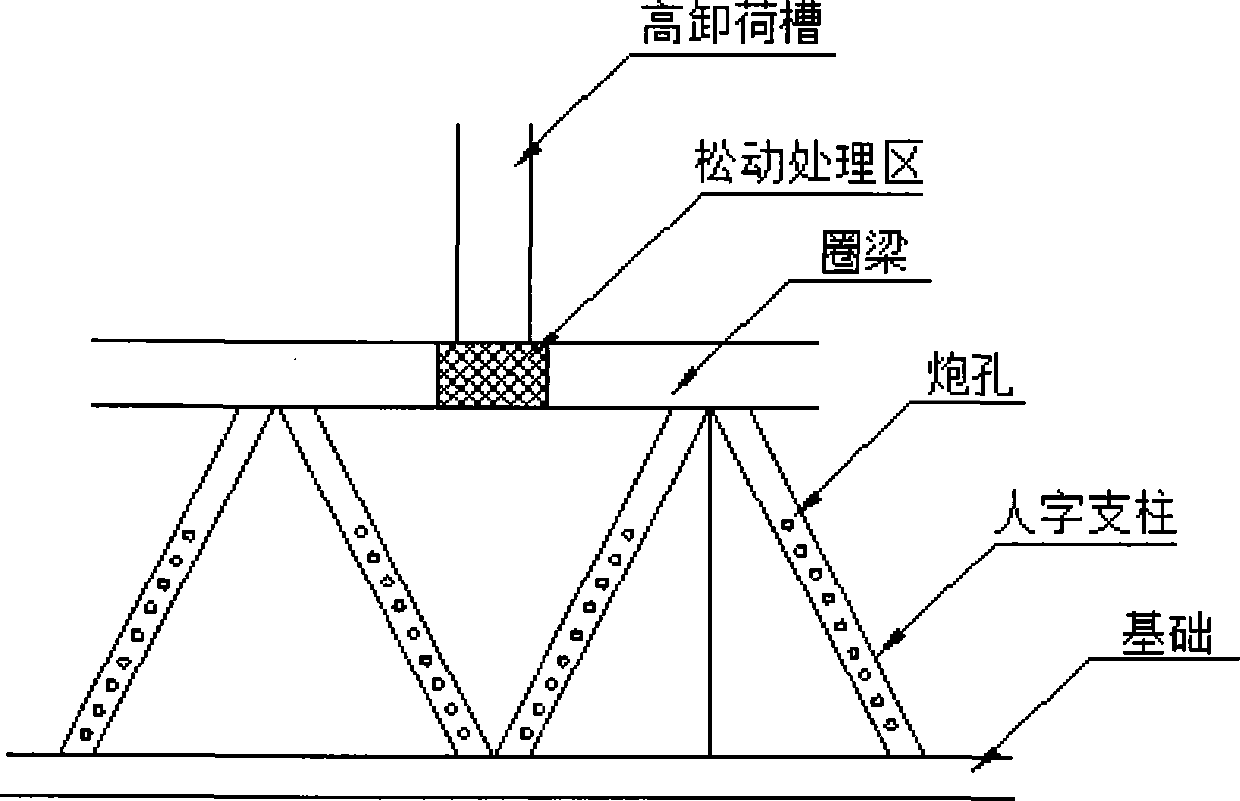

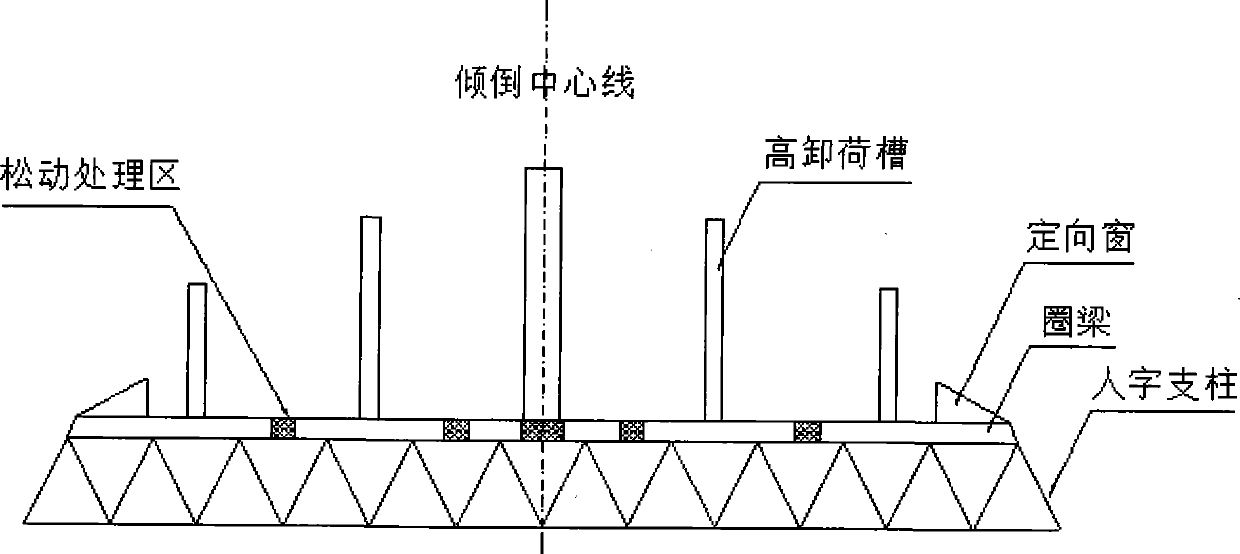

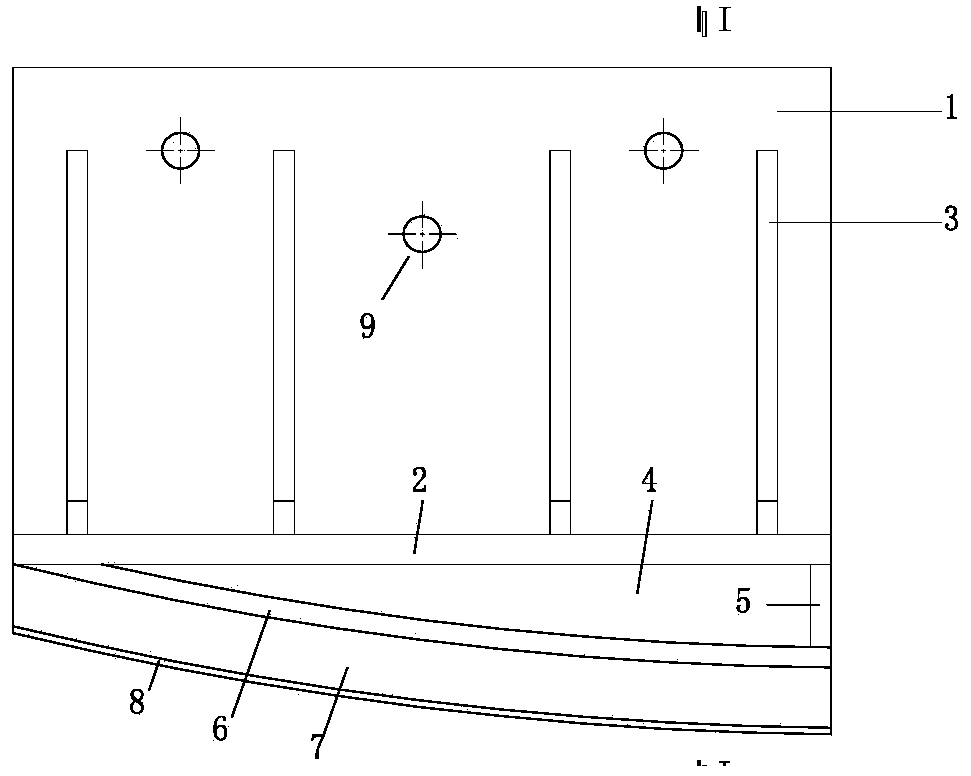

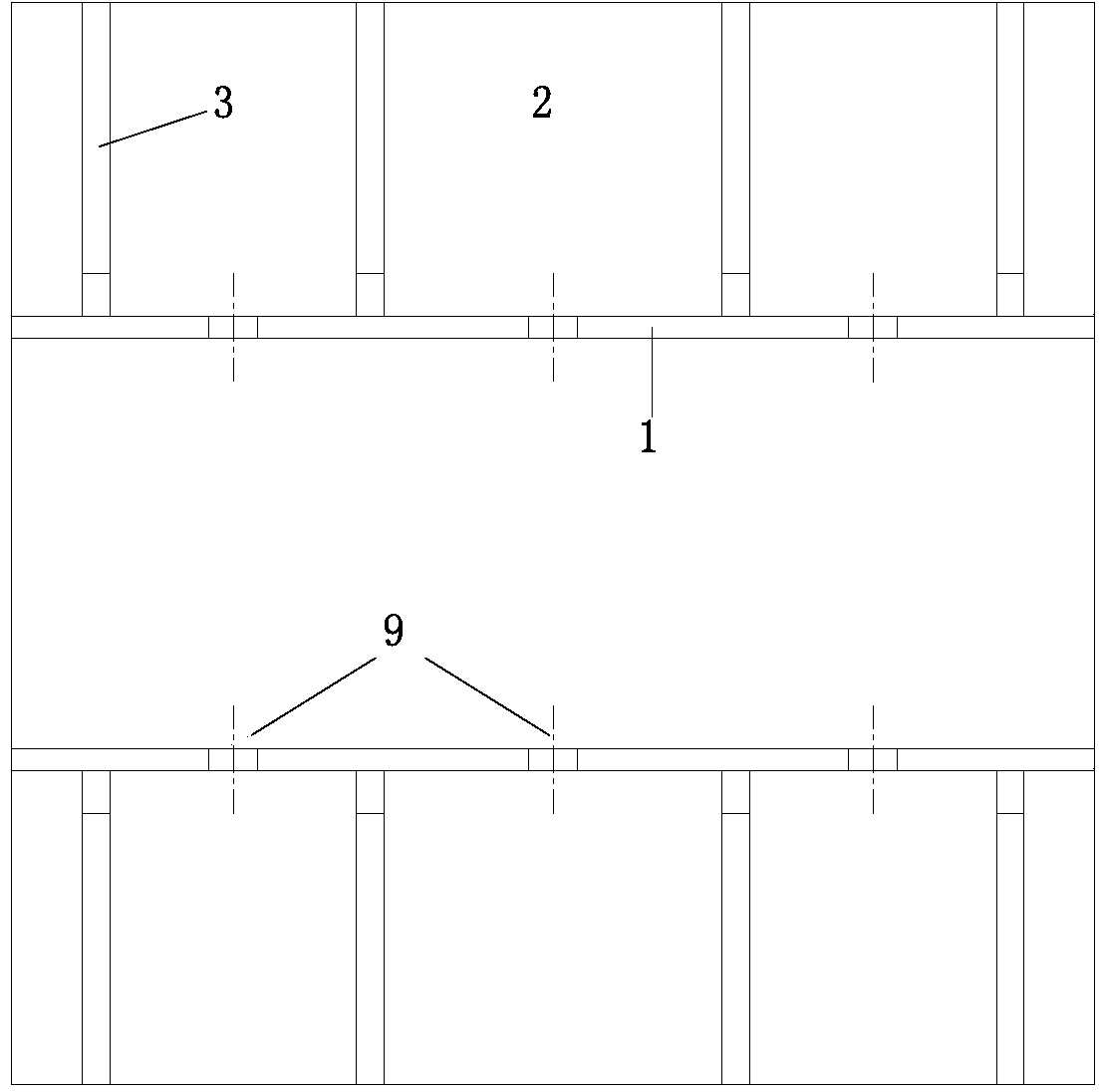

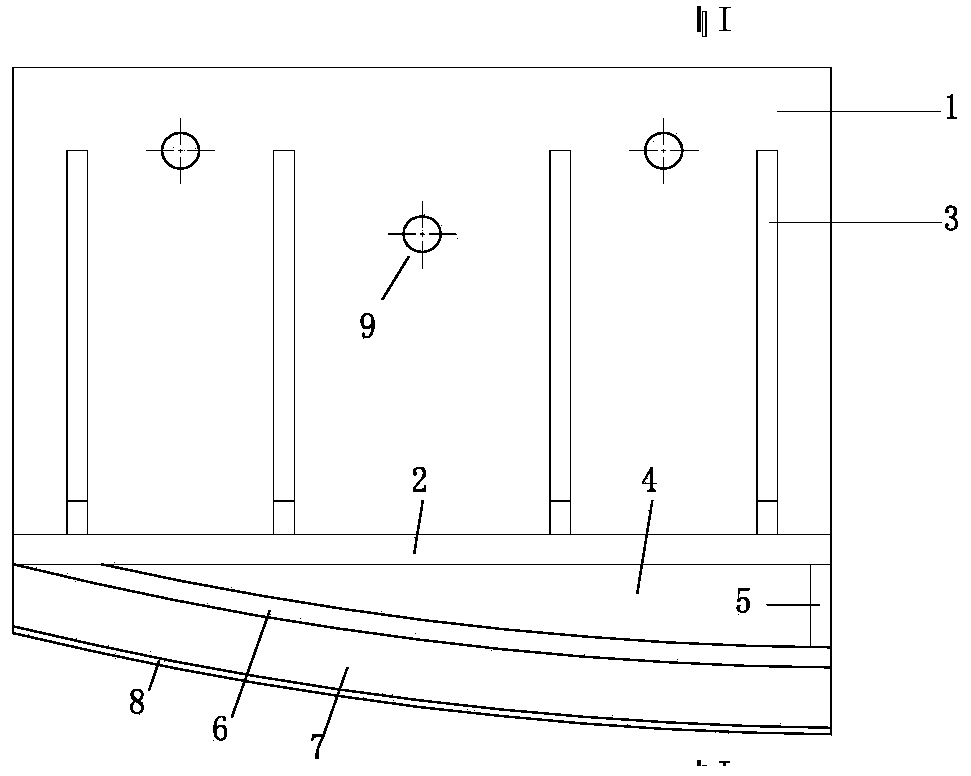

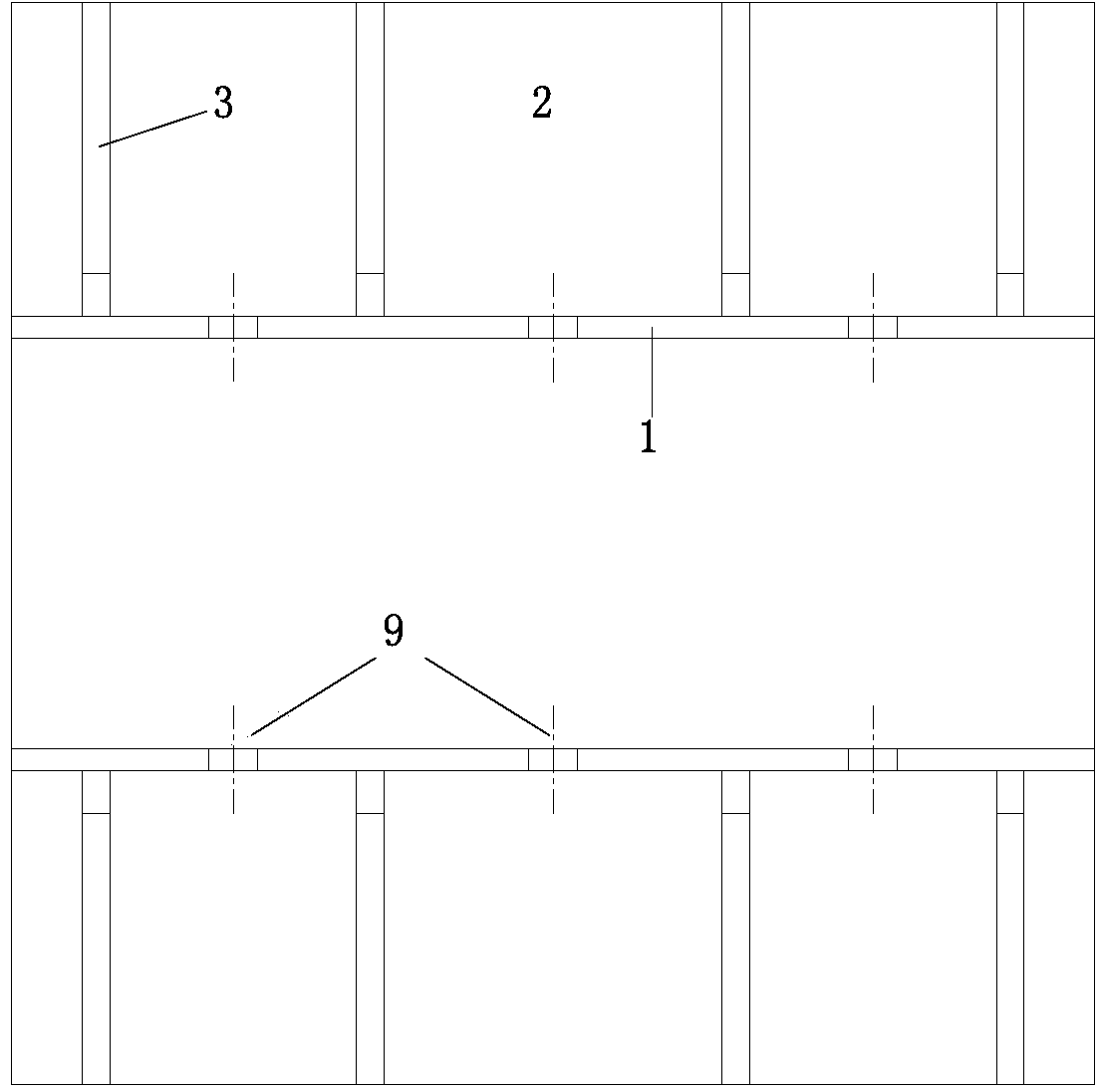

High-unloading slot composite-incision demolition blasting method for reinforced concrete cooling tower

InactiveCN104089550AReduce blasting vibrationReduce drilling workloadBlastingRebarReinforced concrete

The invention discloses a high-unloading slot composite-incision demolition blasting method for a reinforced concrete cooling tower, and relates to a demolition blasting method for the reinforced concrete cooling tower. The demolition blasting method comprises the following steps: pre-demolishing an internal sprinkling platform and an external ladder of the reinforced concrete cooling tower to be demolished by blasting; arranging a composite blasting incision including a rectangular herringbone pillar area, a trapezoidal ring beam area, an acute triangular directional window and a high unloading slot on the lower part of the tower body, wherein the high unloading slot and the directional window are mechanically arranged so as to ensure the construction precision; drilling at the herringbone pillar and a ring beam which is locally required to be loosened by blasting (a ring beam loosening area is constructed by a mechanical method and a blasting method), filling explosive, fencing, and strengthening blasting of a millisecond delay blasting network through non-electric bidirectional multi-point excitation. By the demolition blasting method, the falling direction can be accurately controlled, the number of boreholes and the amount of the explosive can be greatly reduced, the collapsing disintegration degree and the touchdown impact state of the tower body can be regulated and controlled, and the touchdown vibration can be effectively controlled.

Owner:HENAN POLYTECHNIC UNIV

Drainage method of tunnel bedrock groundwater

The invention provides a drainage method of tunnel bedrock groundwater. The method includes: adopting a first drilling tool to drill at the position close to a tunnel entrance for opening a drainage channel along the extension direction of the tunnel; when the length of the drainage channel reaches the first preset position, adopting disposal measures, and then adopting a second drilling tool to continue drilling along the drilling direction of the drainage channel till the length of the drainage channel reaches the second preset position; extracting air in the drainage channel to enable negative pressure to be formed in the drainage channel, and enabling water in the drainage channel to be drained. Drainage range of the drainage channel is enlarged to the largest degree, workload of drilling is reduced, influence caused on travelling cranes is avoided, groundwater can be drained effectively or water pressure can be reduced effectively, and water disasters are reduced.

Owner:CHINA SHENHUA ENERGY CO LTD +1

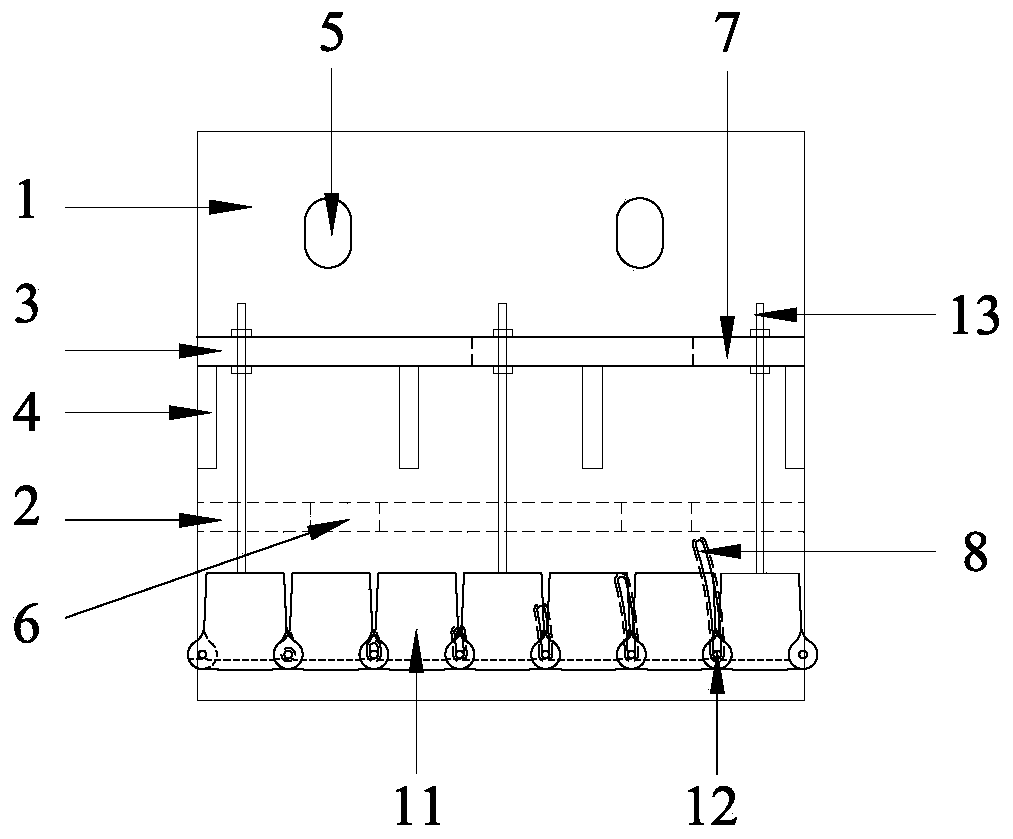

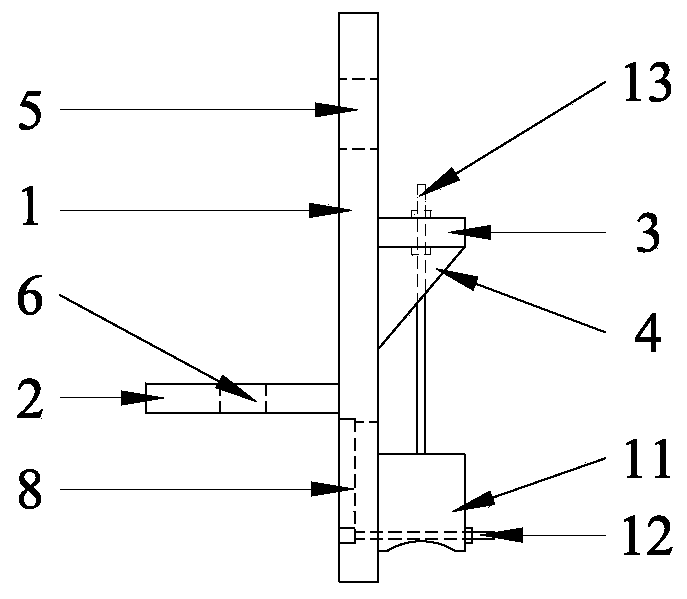

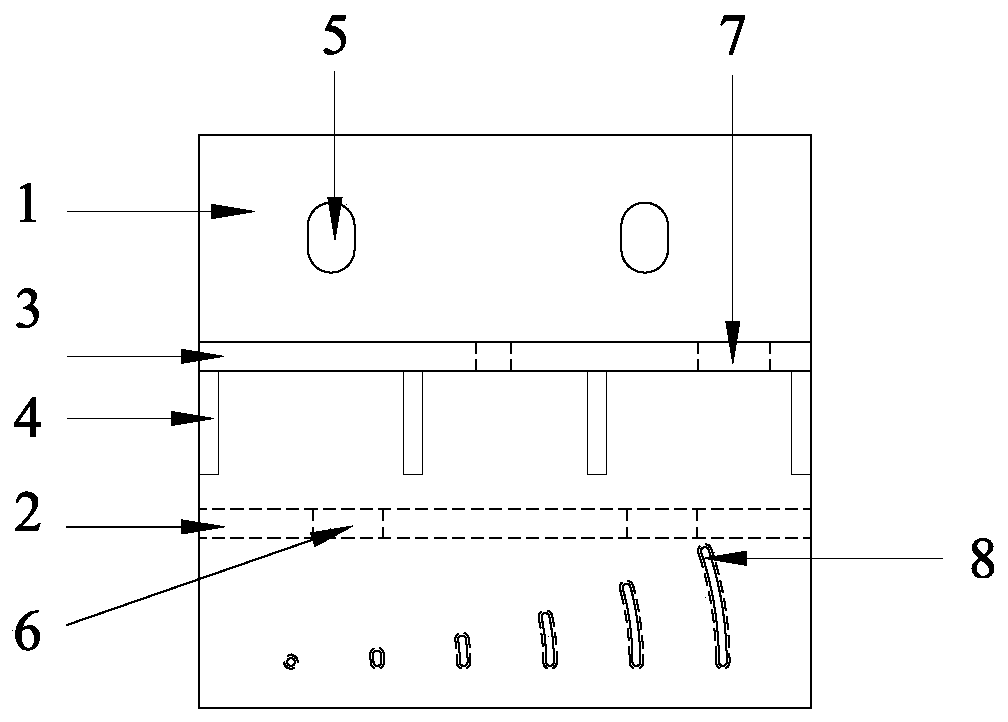

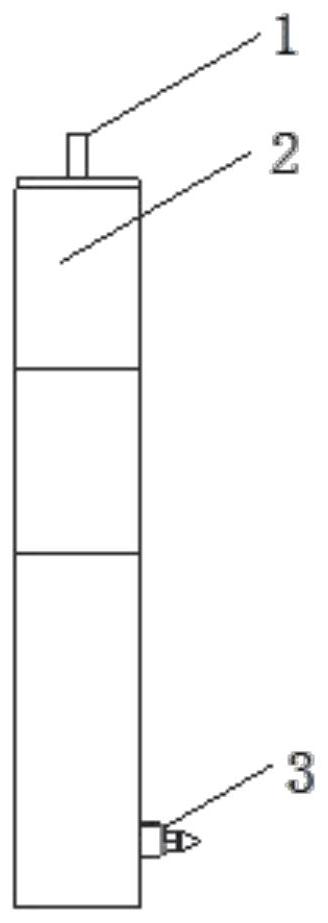

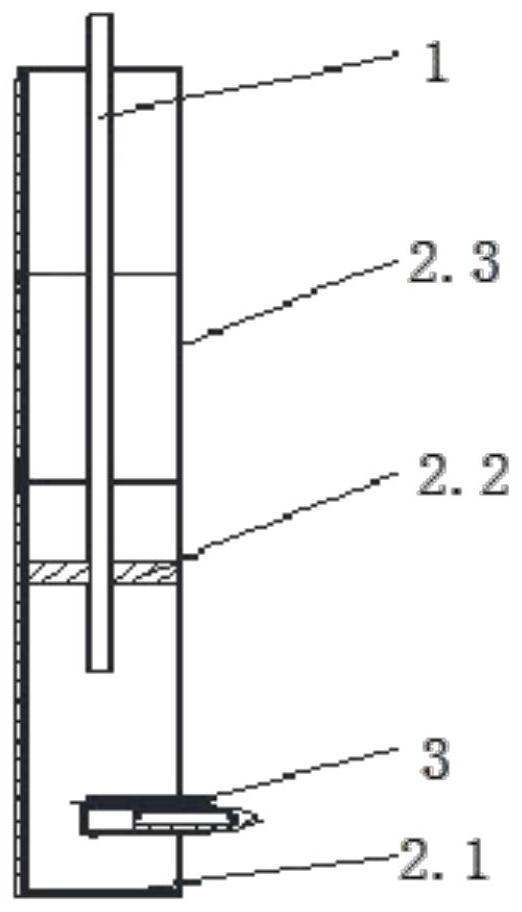

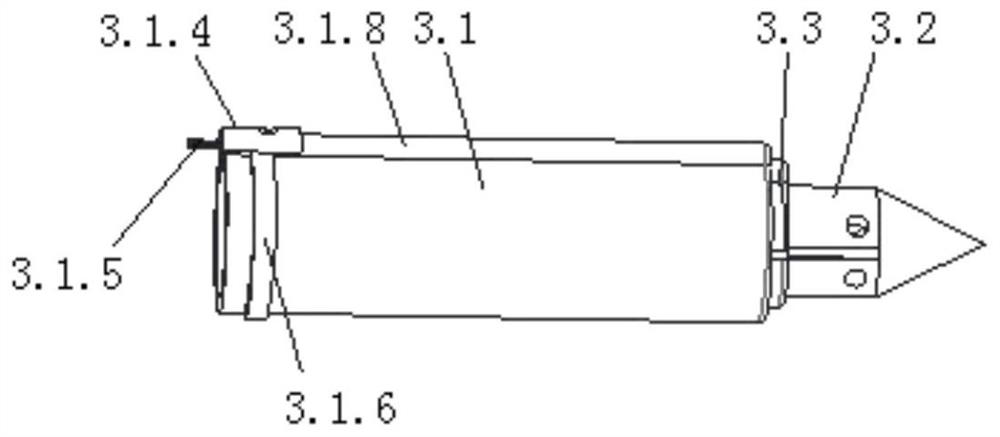

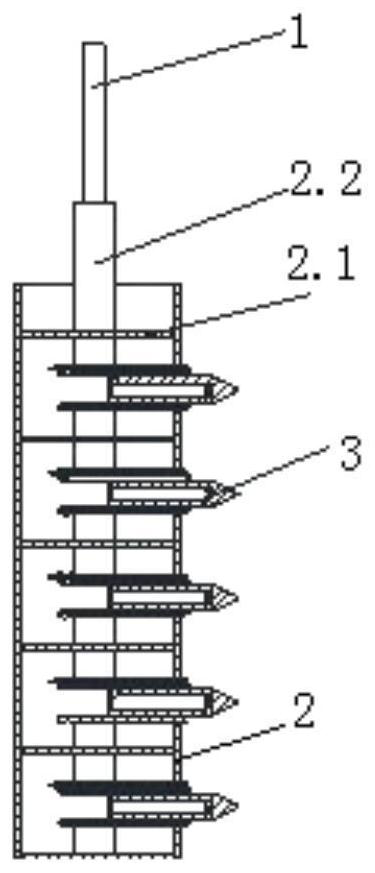

Blasting cutting device with composite charging structure and construction method of blasting cutting device

The invention discloses a blasting cutting device with a composite charging structure and a construction method of the blasting cutting device. The blasting cutting device is composed of a shaped blasting tube, a tail connector, explosives, a detonating cord and a reverse detonating cartridge, wherein the shaped blasting tube comprises an explosive groove with a horn-shaped groove and an outer buckling explosive groove cover; a tube is filled with the explosives and is provided with the detonating cord; the reverse detonating cartridge can be connected with the tail of the tube through the tail connector, and therefore the blasting cutting device is formed; and the blasting cutting device is fixed in a blasting hole by a positioning block. According to the horn-shaped groove in the shapedexplosive tube, the charging structure of the horn-shaped groove can generate higher jet velocity than the charging structure of a cone-angle-shaped groove, and the cutting ability on rock mass is higher. The shaped blasting tube has two types including a common type and a reinforced type. A groove of the common type shaped blasting tube is an opening, a groove notch of the reinforced type shapedblasting tube is closed, a shaped cavity is formed in the groove, on the one hand, the rigidity of the structure can be enhanced, on the other hand, after water is injected into the shaped cavity, high-pressure jet water can be generated during blasting to form a water jet, the cutting ability on the rock mass can be enhanced, and the generated water mist can further play a role in dust removal.

Owner:四川路航建设工程有限责任公司

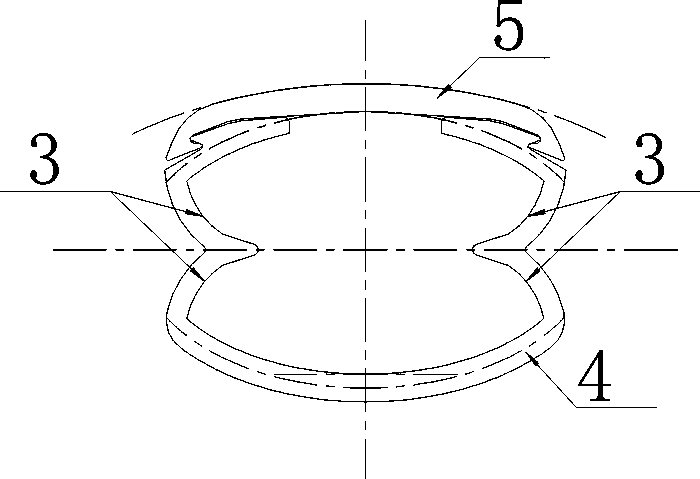

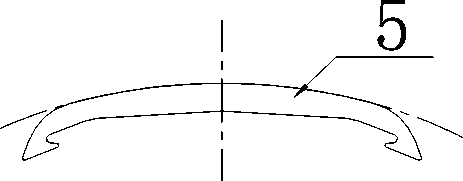

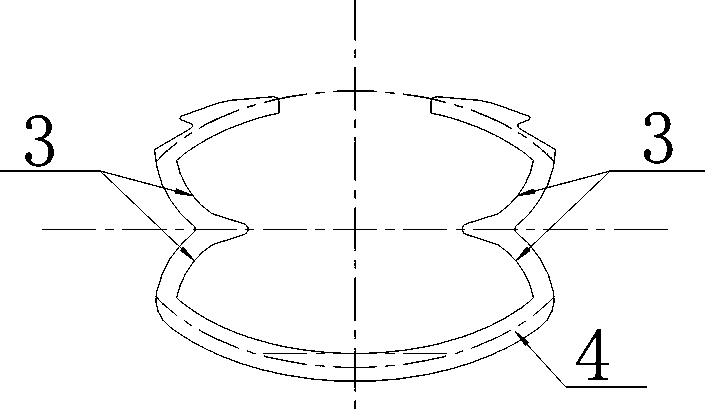

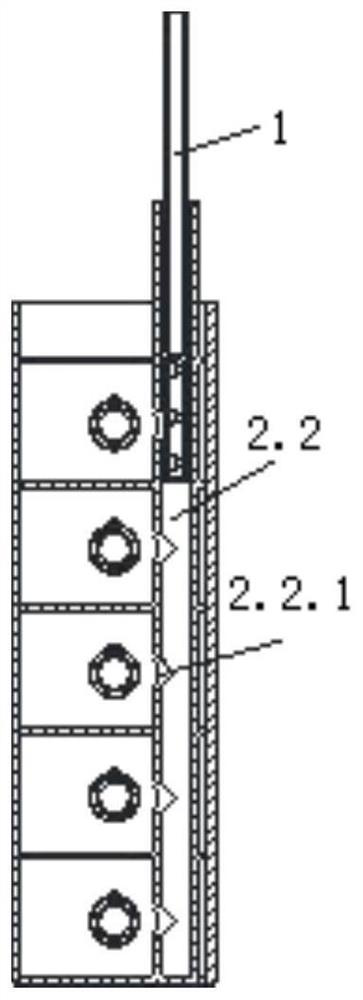

Grouting reinforcement method suitable for weak filler karst cave

ActiveCN111549757AExpand the radius of the grouting areaReduce drilling densitySoil preservationPiston ringSlurry

The invention provides a grouting reinforcement method suitable for a weak filler karst cave. The grouting reinforcement device comprises a grouting pipe, a grouting barrel and a grouting valve, a plurality of partition plates are arranged in the grouting barrel in the height direction of the grouting barrel, a grout containing cavity is formed by every two adjacent partition plates and the side wall of the grouting barrel, a plurality of telescopic grouting valves are connected to the side wall of the grouting barrel in a sliding mode, and each grouting valve is located between the two layersof partition plates; and the end, provided with a grout conveying hole, of the grouting pipe penetrates through the partition plate of the grouting barrel to be in sliding connection with the grouting barrel in the height direction, and piston rings are arranged on the two sides of the grout conveying hole in the height direction of the grouting pipe. The multiple layers of grout containing cavities are formed in the grouting barrel, the grouting valves are arranged on the side walls of all the grout containing cavities, the grouting reinforcement device can be suitable for grouting reinforcement of stratums of different depths only by lifting the grouting pipes, the workload of workers for lifting the whole grouting device can be reduced, and the grouting working efficiency is improved.

Owner:CHINA RAILWAY WUJU GROUP ELECTRIC WORKS ENG CORP +1

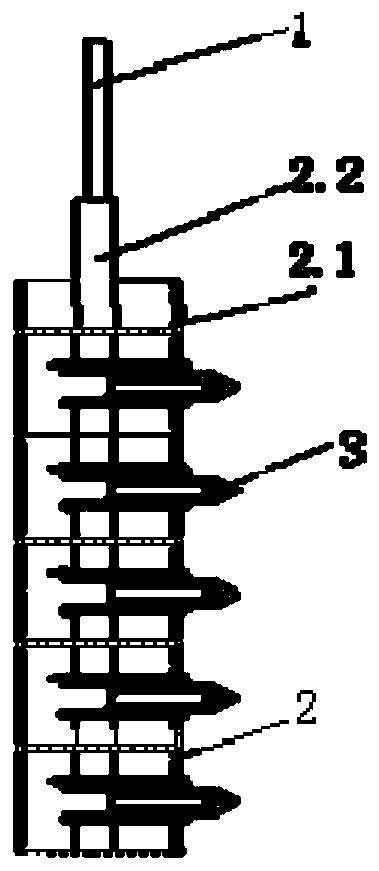

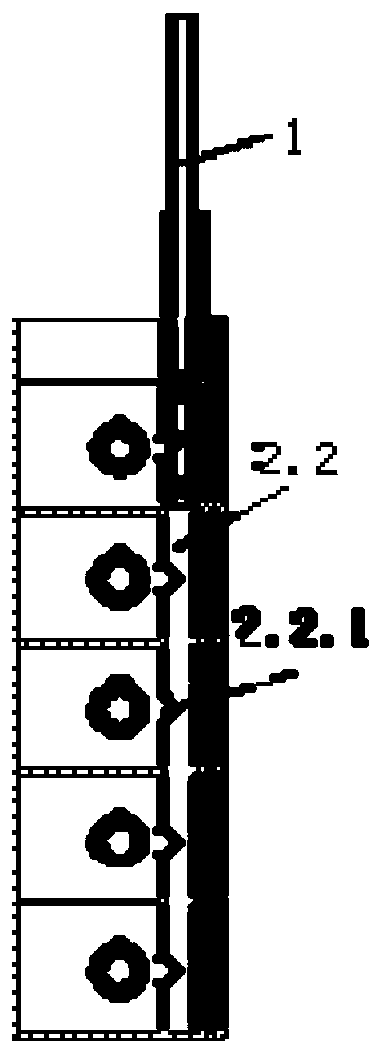

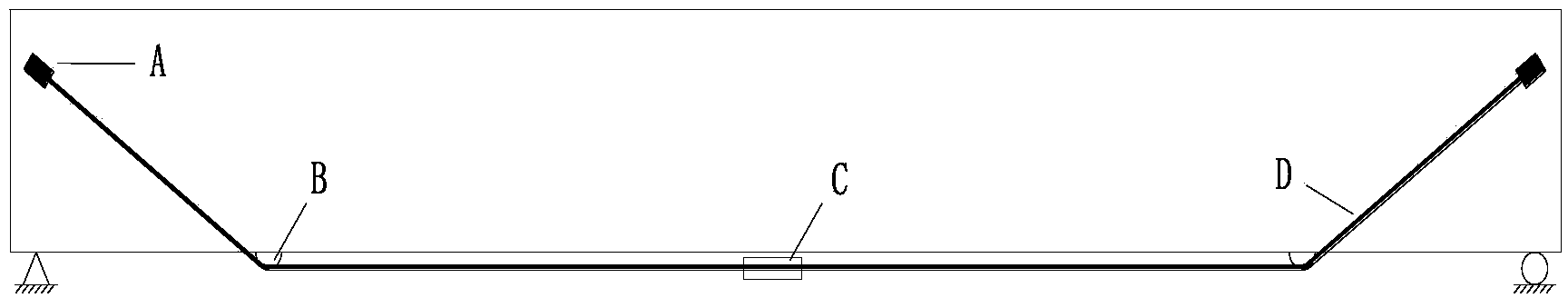

Jacking-type arc-shaped steel plate external-prestressing steel rope diverter

InactiveCN103758047AIncrease stiffnessEnsure tangential fitBridge erection/assemblyBridge strengtheningSupporting systemSheet steel

The invention discloses a jacking-type arc-shaped steel plate external-prestressing steel rope diverter which comprises a supporting system and a reinforcing system. The supporting system is composed of a supporting plate, an arc-shaped steel plate, multiple connecting plates and a cavity sealing plate, the top face of the supporting system is the supporting plate of a rectangular structure, the top face of the supporting plate is jacked on the bottom face of a beam, the arc-shaped steel plate is arranged on the bottom face of the supporting plate, one end of the arc-shaped steel plate is in welded connection with the supporting plate, an internal cavity is formed between the supporting plate and the arc-shaped steel plate, the connecting plates are arranged in the internal cavity, the cavity sealing plate is arranged at the other end of the supporting plate, the bottom face of the arc-shaped steel plate receives steering bearing pressure of an external steel rope, the reinforcing system is composed of beam-side clamping plates and reinforcing plates which are symmetrically arranged on two sides of the beam, and the beam-side clamping plates and the reinforcing plates are connected on the top face of the supporting plate, and used for connecting the diverter with the beam and improving rigidity of the supporting system. The jacking-type arc-shaped steel plate external-prestressing steel rope diverter is safe, reliable and large in turning radius, the steel rope and the diverter are maintained to be in tangential attachment, and convenience is brought to mounting.

Owner:HUAZHONG UNIV OF SCI & TECH +1

Unmanned gas extraction method by hydraulic perforation

ActiveCN108678804AChange the mechanical environmentImprove breathabilityMining devicesFluid removalThermodynamicsGas passing

The invention provides an unmanned gas extraction method by hydraulic perforation. The gas extraction method comprises the following steps: firstly perforating is performed at a center line of a coalbody in a forward direction of a coal roadway driving face to form a high-pressure hydraulic perforation by utilizing a high-pressure hydraulic perforating gun, and then fracturing is performed in thecoal body around the high-pressure hydraulic perforation by utilizing a high-pressure hydraulic fracturing gun, so that a high-pressure hydraulic fracture hole with cracks is obtained, and the high-pressure hydraulic fracture hole acts as an outflow passage for gas in the coal body, and then a gas safety isolation air bag and a gas extraction pipe are arranged in the rear roadway of the coal body, the gas extraction pipe runs through the gas safety isolation air bag to the interior of the high-pressure hydraulic fracture hole, and the gas is extracted through the gas extraction pipe; with theadoption of the gas extraction system provided by the invention, the working efficiency in the process of roadway driving and rock cross-cut coal uncovering is improved, the safety of construction personnel is ensured, and the gas in the coal body in front of the driving face and in front of the rock cross-cut coal uncovering can be extracted safely, efficiently and quickly.

Owner:ANHUI UNIV OF SCI & TECH

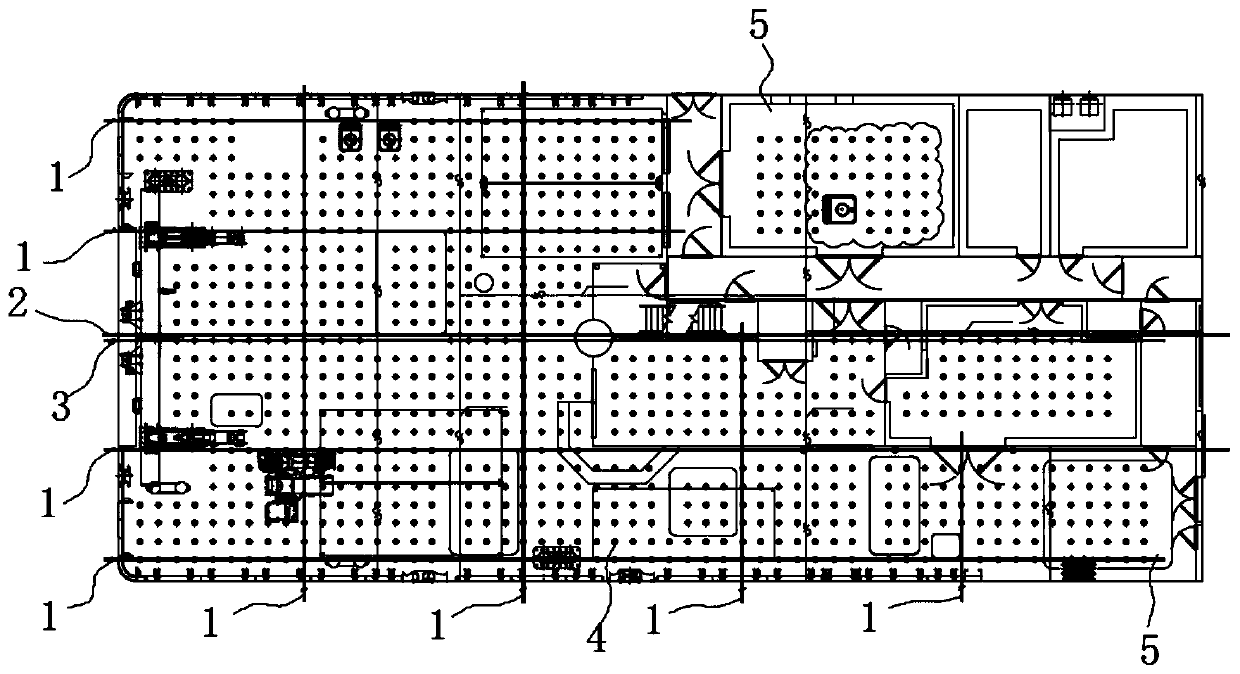

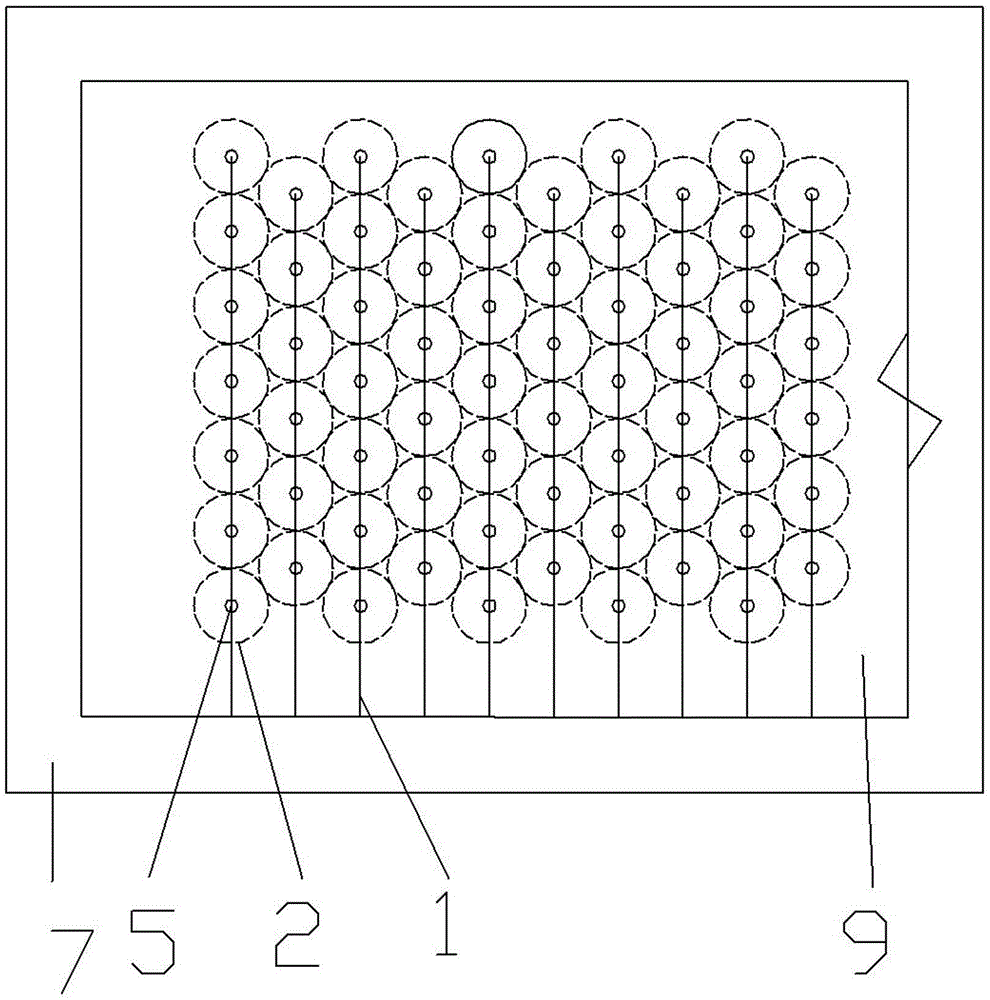

Ship anchor bolt installation scribing method

ActiveCN110053707AReduce drilling workloadHigh precisionVessel designingOther workshop equipmentPosition errorMesh grid

The invention discloses a ship anchor bolt installation scribing method which comprises the steps that a first datum line is scribed on a deck in advance in the captain direction or the ship width direction of a ship, then a second datum line is scribed at a distance of n references from the first datum line, the distance between the first datum line and the second datum line is measured and compared with design requirements, the second datum line is determined if the condition is met, and the position of the second datum line is adjusted if the condition is not met; and finally, a following third datum line is scribed to the x <the> datum line according to the method, so that the datum lines are scribed correspondingly in the captain direction and the ship width of the ship, and small grids are equally scribed according to the distance between every two adjacent datum lines to determine the forming position of anchor bolt mounting holes. Position errors of structural parts generate onthe deck during the assembly process of the ship can be dispersed into each large grid, and the small grids are scribed by evenly dividing the large grids, so that the errors are divided and digestedby each small grid divided on the deck.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Method for extracting coalbed gases from coal mines by upper and lower combination

The invention relates to coalbed gas mining technology, in particular to a method for extracting coalbed gases from coal mines by upper and lower combination. The method solves the problem of poor gas drainage effects through surface well drilling and hole drilling in the coalbed. The method comprises the following steps: constructing extraction drilled wells on the surface, constructing underground directional long drilled holes in the coalbed, crosslinking the fracture areas of the extraction drilled wells with the drainage areas of the underground directional long drilled holes, then effectively sealing the underground directional long drilled holes in the coalbed, then utilizing fracturing equipment on the surface to fracture the drainage areas drilled on the surface and the drainage areas of the long drilled holes in the coalbed via the extraction drilled wells and finally carrying out extraction. The method has the advantages of improving the extraction rate and efficiency of the coalbed gases and shortening the construction period of the coalbed gas extraction engineering.

Owner:山西蓝焰煤层气集团有限责任公司

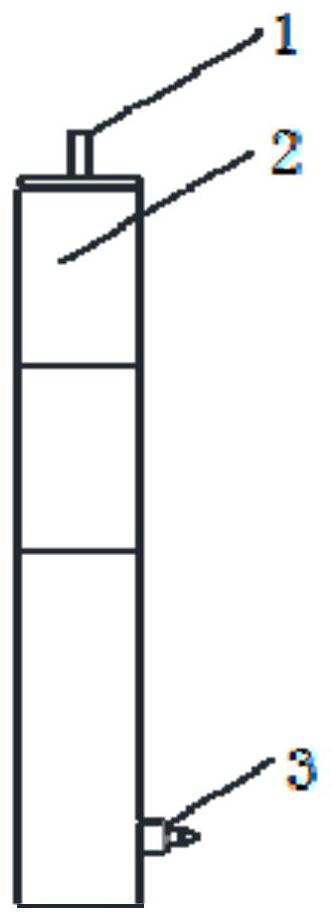

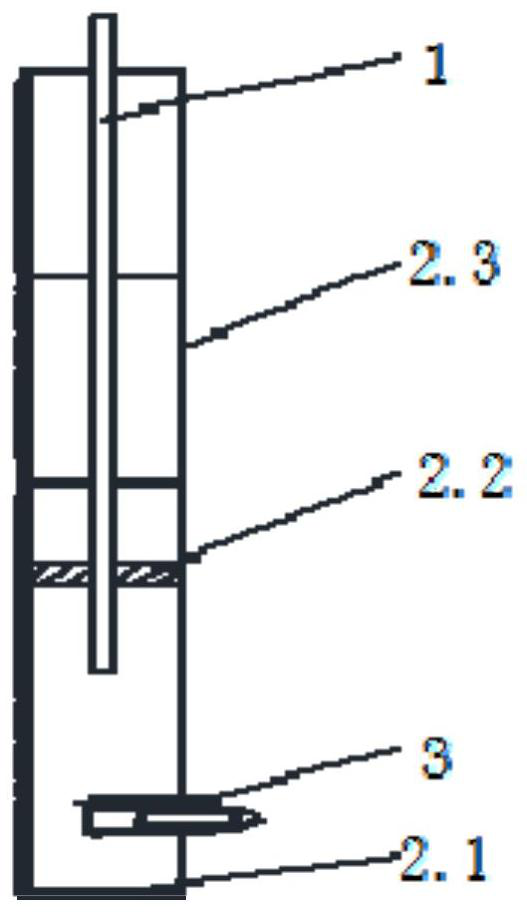

Energy-gathering hydraulic-control blasting cartridge

PendingCN109099781AReduce dosageIncrease the spacing of blasting drill holesExplosive chargesWater vaporEngineering

The invention discloses an energy-gathering hydraulic-control blasting cartridge. The energy-gathering hydraulic-control blasting cartridge comprises a cylindrical cartridge body and an outer packaging bag and is characterized in that arc-shaped faces are symmetrically arranged in the cartridge body, and the arc-shaped faces sequentially separate the interior of the cartridge body into a first energy gathering cavity, a dynamite cavity and a second energy gathering cavity. The energy-gathering hydraulic-control blasting cartridge has the advantages that high-pressure hydraulic jet and water wedge effect is increased by energy-gathering hydraulic-control blasting, the effects of smooth blasting or presplitting blasting are increased, dynamite use amount is reduced, blasting drilling interval is increased, drilling workload is reduced, and water mist and steam are formed during blasting to suppress dust and improve the operation environment.

Owner:陕西沣采能源材料科技有限公司

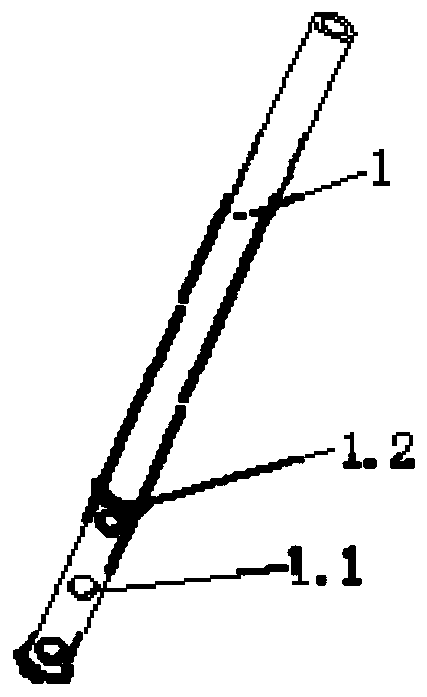

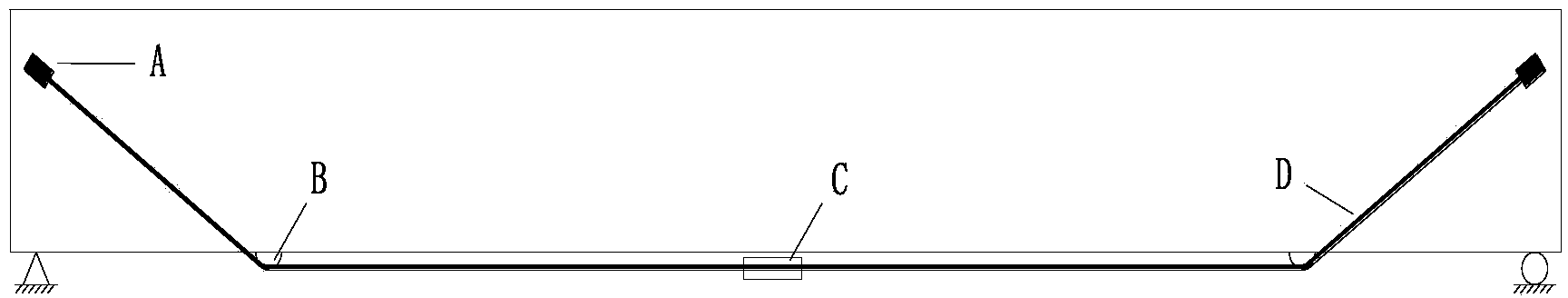

Curvature-variable multipurpose turning device for external prestressed reinforcing steel

ActiveCN109797984AAchieve steeringAvoid damageBuilding repairsBuilding material handlingSupporting systemPre stress

The invention discloses a curvature-variable multipurpose turning device for external prestressed reinforcing steel. The curvature-variable multipurpose turning device comprises a supporting system and a curvature-variable turning system and is characterized in that the supporting system comprises a supporting body and a support plate, and the support plate is fixed to the supporting body; the supporting body is provided with a plurality of displacement adjusting grooves; the curvature-variable turning system comprises a turning component, a first fastening device and a second fastening device, the turning component comprises a plurality of turning units, and the bottom of each turning unit is provided with a groove for placing prestressed reinforcing steel; the first fastening device andthe second fastening device are connected with the turning component, and different turning radiuses can be achieved by adjusting the positions of different turning units on the displacement adjustinggrooves. The curvature-variable multipurpose turning device is safe, reliable, adjustable in turning radius, applicable to the external prestressed reinforcing steel of various diameters, convenientto transport, convenient to mount and the like.

Owner:SOUTHEAST UNIV

Jacking-type arc-shaped steel plate external-prestressing steel rope diverter

InactiveCN103758047BIncrease stiffnessSolve the rustBridge erection/assemblyBridge strengtheningSupporting systemSheet steel

The invention discloses a jacking-type arc-shaped steel plate external-prestressing steel rope diverter which comprises a supporting system and a reinforcing system. The supporting system is composed of a supporting plate, an arc-shaped steel plate, multiple connecting plates and a cavity sealing plate, the top face of the supporting system is the supporting plate of a rectangular structure, the top face of the supporting plate is jacked on the bottom face of a beam, the arc-shaped steel plate is arranged on the bottom face of the supporting plate, one end of the arc-shaped steel plate is in welded connection with the supporting plate, an internal cavity is formed between the supporting plate and the arc-shaped steel plate, the connecting plates are arranged in the internal cavity, the cavity sealing plate is arranged at the other end of the supporting plate, the bottom face of the arc-shaped steel plate receives steering bearing pressure of an external steel rope, the reinforcing system is composed of beam-side clamping plates and reinforcing plates which are symmetrically arranged on two sides of the beam, and the beam-side clamping plates and the reinforcing plates are connected on the top face of the supporting plate, and used for connecting the diverter with the beam and improving rigidity of the supporting system. The jacking-type arc-shaped steel plate external-prestressing steel rope diverter is safe, reliable and large in turning radius, the steel rope and the diverter are maintained to be in tangential attachment, and convenience is brought to mounting.

Owner:HUAZHONG UNIV OF SCI & TECH +1

A grouting reinforcement method suitable for karst caves with weak fillings

ActiveCN111549757BExpand the radius of the grouting areaReduce drilling densitySoil preservationPiston ringKarst

Owner:CHINA RAILWAY WUJU GROUP ELECTRIC WORKS ENG CORP +1

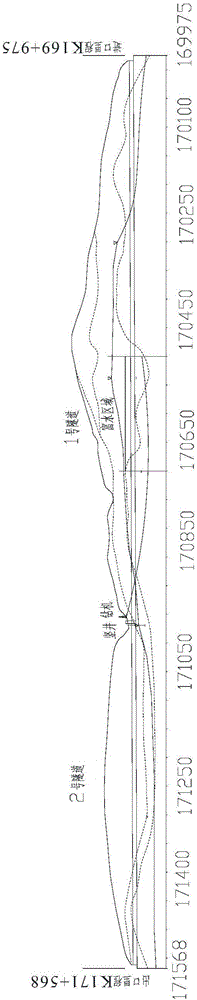

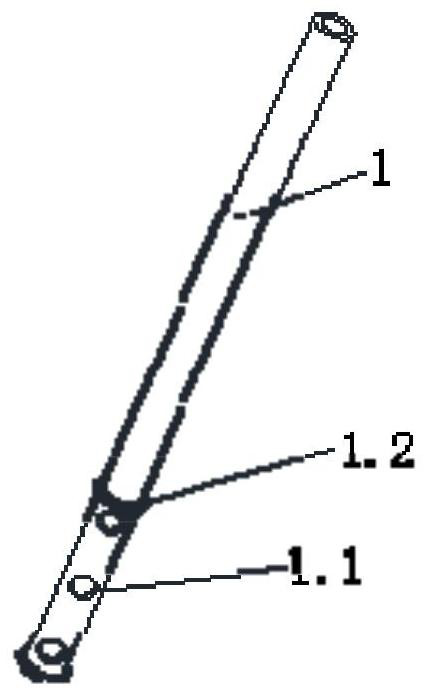

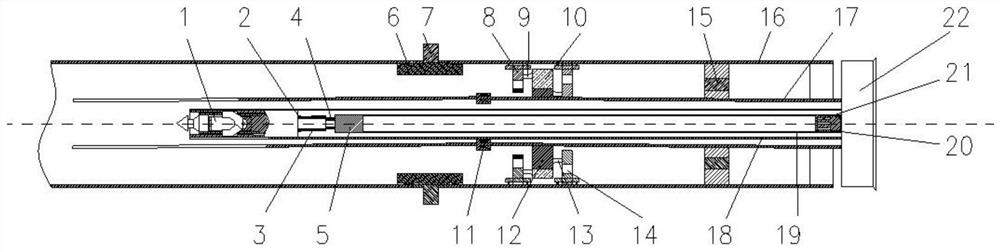

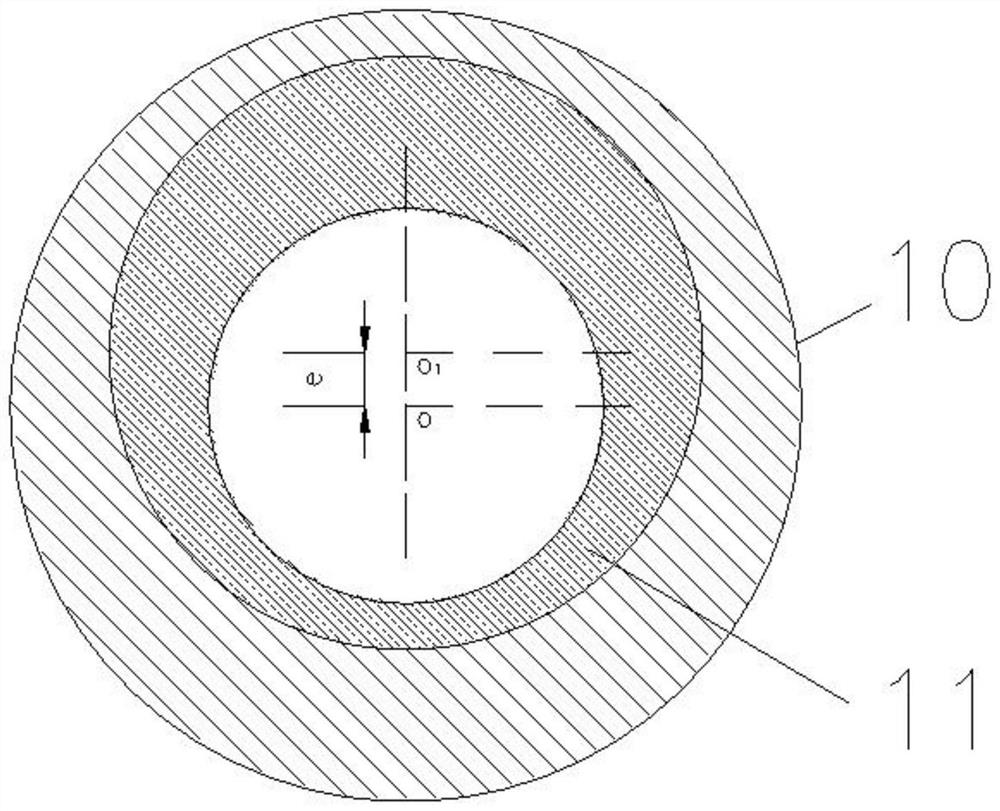

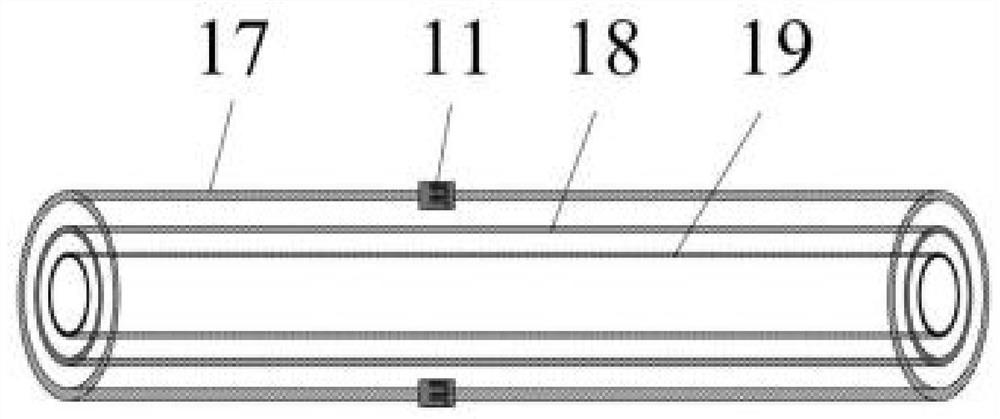

A Spline Type Horizontal Directional Drilling Engineering Geological Exploration Control Device

ActiveCN112252971BEasy to controlTrue reactionDirectional drillingBorehole/well accessoriesTerrainStructural engineering

The spline-type horizontal directional drilling engineering geological survey control device provided by the present invention combines coring and fishing parts with eccentric guiding parts, and uses inner and outer eccentric ring control motors to control the inner and outer eccentric rings for different combinations to obtain different eccentric distances. The spline is used as a joint point to make a certain degree of bending within the elastic variation range from one end of the core outer tube to the spline part, thereby realizing the directional deflection of the core bit, and then measuring the probe to explore the surrounding geological conditions, and then according to the exploration situation , Carry out another directional build-up, and achieve precise control of the drilling axis through multiple build-ups. At the same time, the coring and salvage components can be used for coring and salvage at any time, truly reflecting the geological conditions along the underground line. If it is applied to the engineering geological survey of ultra-long-distance and deep-buried tunnels, the equipment can be arranged at the entrance and exit of the tunnel, thus avoiding the relocation of equipment in complex terrain conditions and greatly reducing the drilling work of traditional engineering geological surveys quantity.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

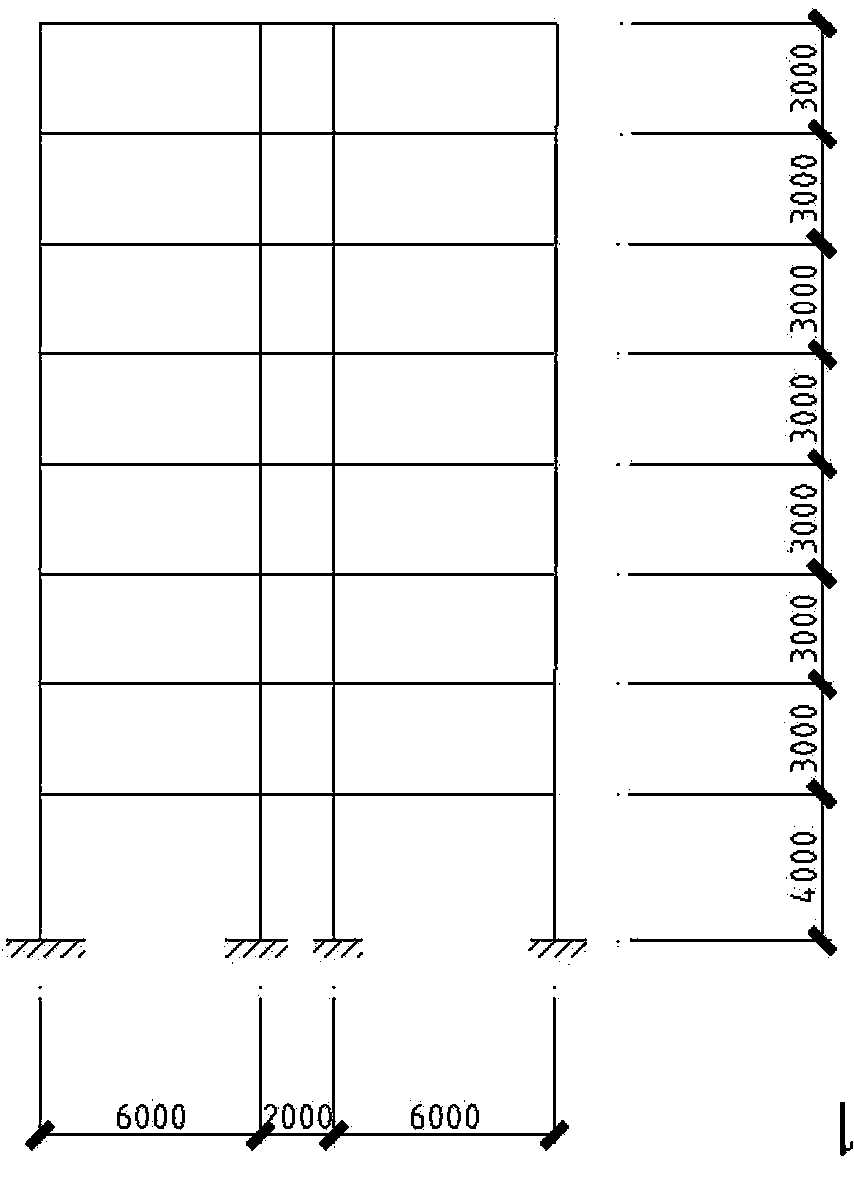

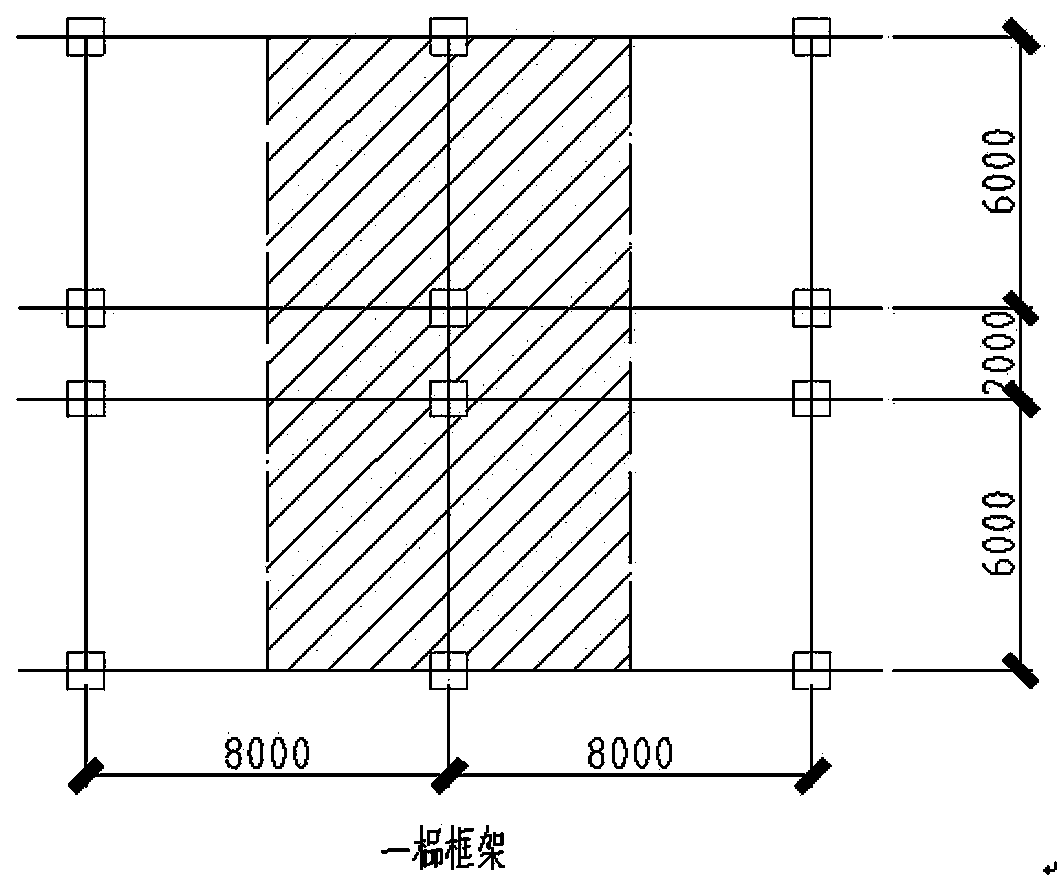

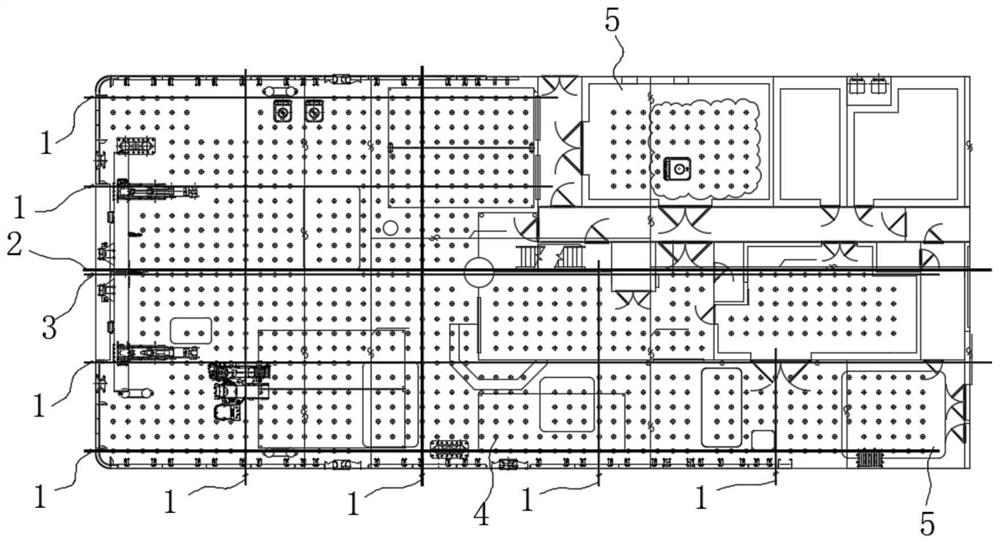

A Simple Calculation Method for Infill Wall Tendons in Frame Structures

ActiveCN107905607BProve unreasonableReduce drilling workloadProtective buildings/sheltersShock proofingDesign standardEconomic benefits

The invention discloses a simple calculating method for lacing bars of a frame structure infilled wall. The simple calculating method comprises the steps that firstly, seismic shear force borne by each layer of a building is calculated, then the number of wall segments of the infilled wall of all the layers which participating in resisting the horizontal seismic shear force is determined, then theseismic shear force capable of being resisted by all the wall segments between the layers is determined, then the remained seismic shear force V of the r layer is determined, the remained seismicshear force V of each layer needs to meet the formula that V is less than or equal to 2n*omega*P, taking the formula that V is less than or equal to 2n*omega*P as the precondition, the lacing bar design scheme that the using number of the lacing bars is the least, and the layer-to-layer space between the lacing bars is not more than 1000 mm according to the design standard requirement of masonryis selected, and the type of the selected lacing bars is determined. The simple calculating method for the lacing bars of the frame structure infilled wall overthrows the arrangement form that the lacing bars are arranged according to the structure in a traditional design idea, seriously-unreasonable traditional arrangement of the lacing bars is proved, meanwhile, traditional convention that the lacing bars are not required to be calculated is abandoned, the lacing bars are required to be determined through simple calculation, it is ensured that the infilled wall does not collapse under frequently occurred earthquakes, the drilling work amount of embedded steel bars is greatly reduced, and economic benefits are increased.

Owner:ECONOMIC TECH RES INST OF STATE GRID HENAN ELECTRIC POWER +2

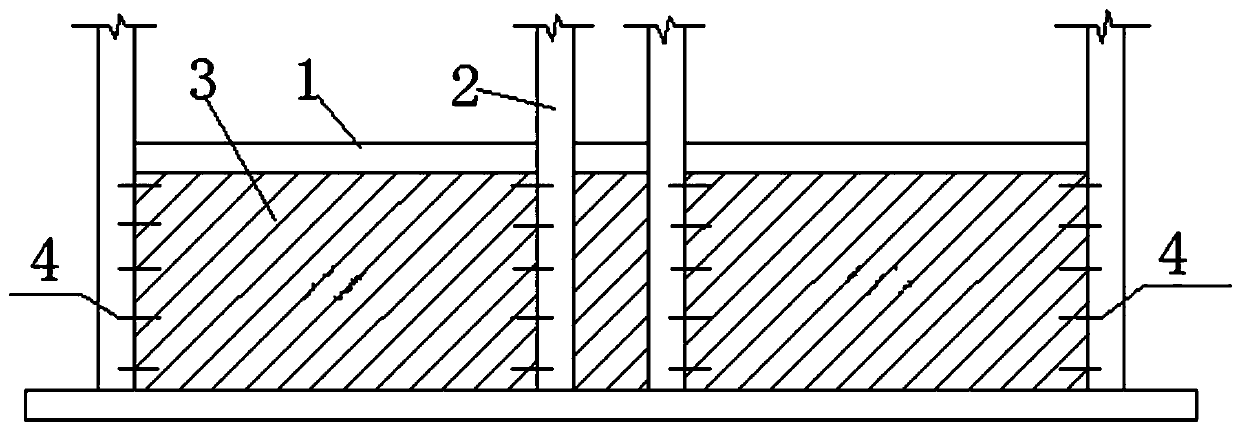

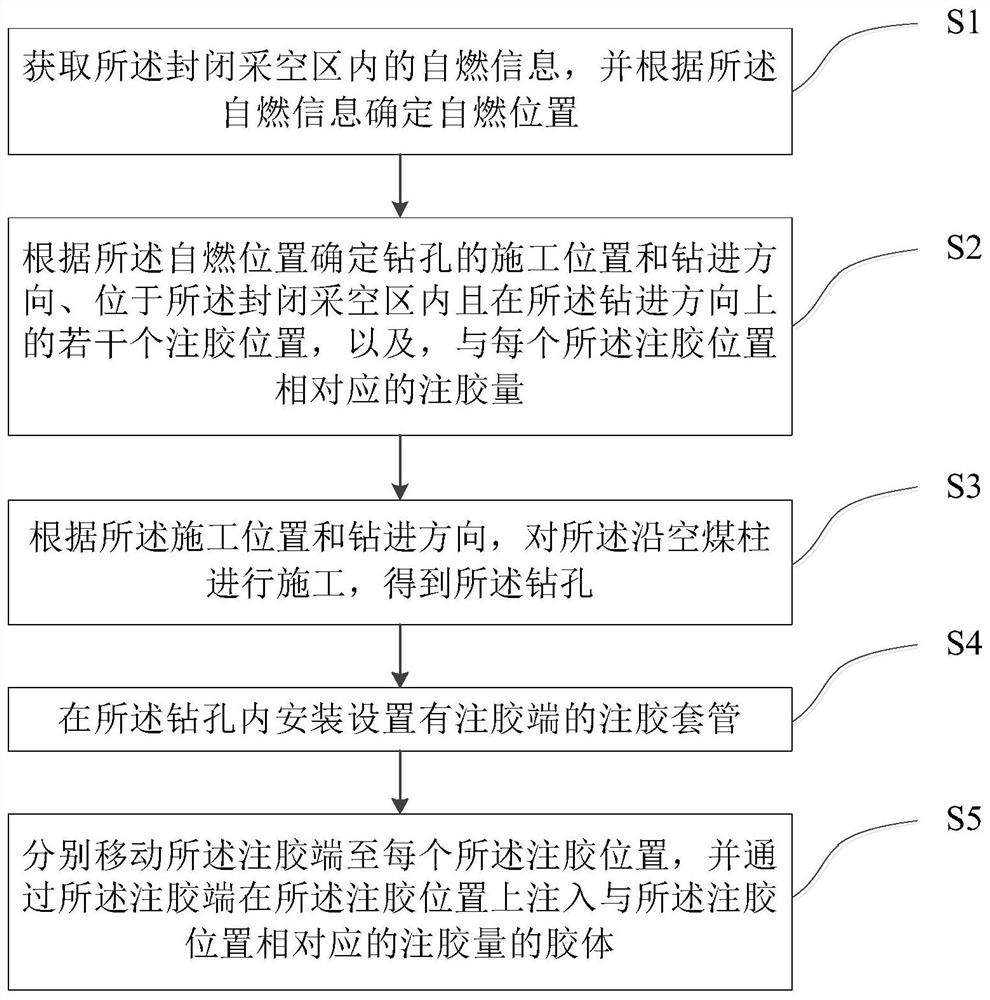

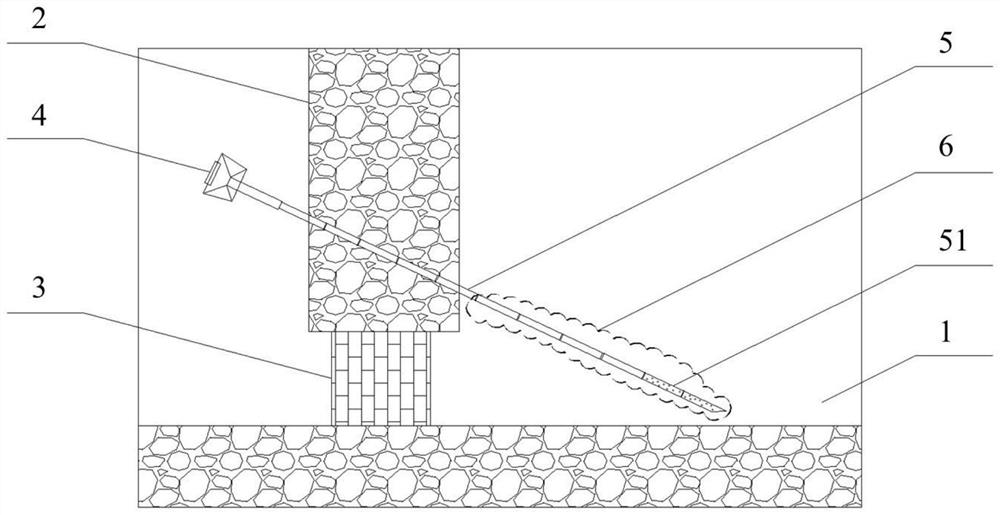

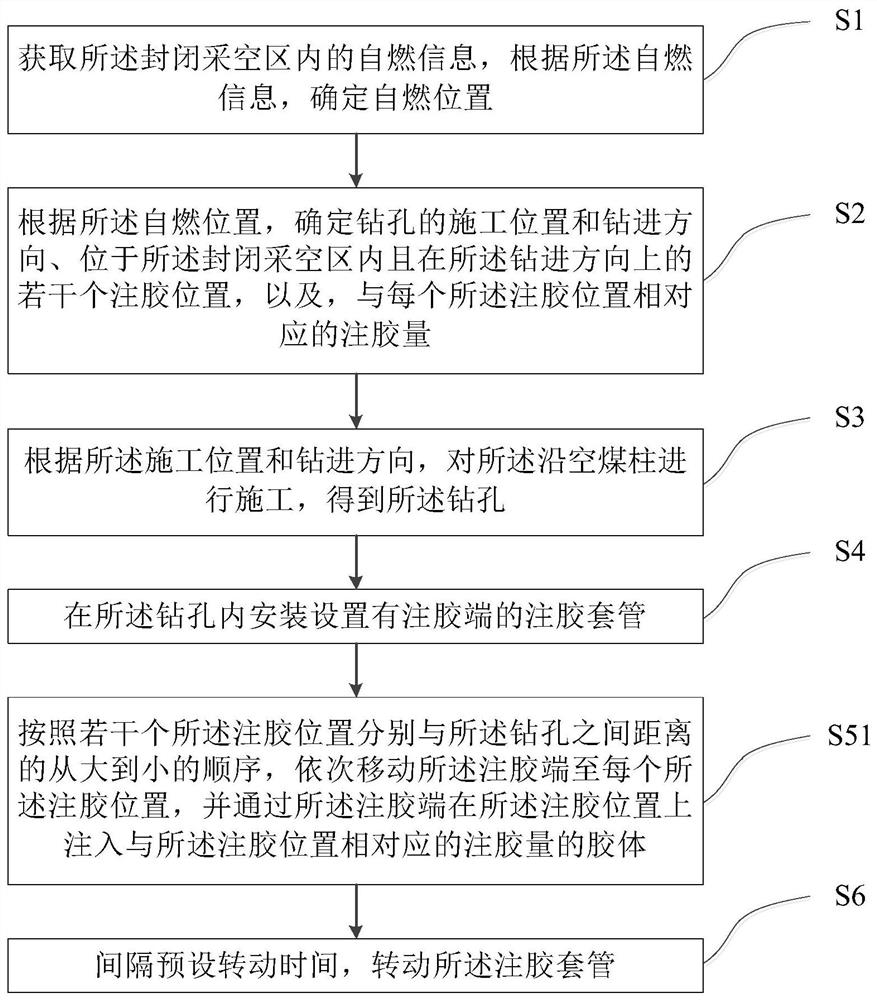

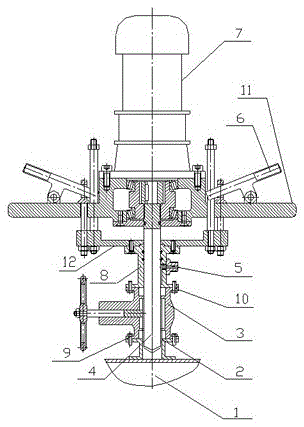

Fire prevention and extinguishing linear glue injection method

PendingCN112576298AQuick and effectiveSolve the problem of inefficiency in fire prevention and treatmentMining devicesDust removalSpontaneous combustionEngineering

The invention provides a fire prevention and extinguishing linear glue injection method. The method comprises the following steps of: determining a spontaneous combustion position according to spontaneous combustion information; determining a construction position and a drilling direction of a drill hole, a plurality of glue injection positions in the drilling direction and corresponding glue injection amounts at the glue injection positions according to the spontaneous combustion position; obtaining the drill hole through construction; mounting a glue injection sleeve with a glue injection end on the drill hole; moving the glue injection end to the glue injection positions respectively; and injecting glue. According to the fire prevention and extinguishing linear glue injection method, the glue is injected at the glue injection positions in the drilling direction, so that the glue can directly cover and extinguish an ignition point, or a glue isolation belt is formed at an estimated position of the ignition point and near the estimated position, and furthermore, oxygen near the ignition point is reduced, and the aim of suffocating the ignition point is realized. The linear glue isolation belt can be formed by only operating one drill hole, so that the problem of low efficiency in fire prevention and extinguishing treatment in a point type glue injection manner in the prior artcan be solved.

Owner:兖矿能源集团股份有限公司

Explosion-proof and pollution-proof drilling machine

ActiveCN102451924BAvoid pollutionAvoid wastingBoring/drilling componentsBoring/drilling machinesTransformerLiquid gas

The name of the present invention is explosion-proof and pollution-proof drilling machine. The utility model belongs to the technical field of main transformer maintenance of an electric locomotive and connection of liquefied gas and oil branch pipelines. The utility model mainly solves the problems of easy generation of sparks, heavy workload and long time consumption when existing drilling machines drill holes on the main transformer. Its main features include explosion-proof motor, twist drill, fixed bracket, movable bracket, butt flange, gate valve and connecting flange; the fixed bracket is fixed on the explosion-proof motor body, the movable bracket is connected with the fixed bracket through a screw, and the There is a control handle for adjusting the lifting of the screw; the butt flange, the gate valve and the connecting flange are connected in sequence, and are set on the twist drill; the butt flange is fixedly connected with the movable support, and there are inlet and outlet ports on it. The invention has the characteristics of no need to discharge compressor oil, no sparks, small workload, short time consumption and low cost, and is mainly used for main transformer drilling and liquefied gas and oil delivery pipelines to connect branch pipelines when maintaining electric locomotives.

Owner:CRRC LUOYANG CO LTD

Coalbed Methane Extraction Method for Downhole Long Drilling Boreholes Consecutively

ActiveCN103061798BImprove drilling single-hole drainage production capacityImprove extraction efficiencyDrill bitsGas removalDrill siteCoal

The invention relates to a method for extracting coal bed methane through down-hole bedding long borehole consecutive cave building and a hydraulic mechanical drill with the diameter changed and enlarged while drilling. A coal bed bedding long borehole is combined with a cave building technology, and the permeability of low-permeable coal reservoirs and the coal bed borehole extraction capacity are improved. A hole is opened at 1 / 3 coal thickness or 1.5m upwards away from the coal heading floor on the extracting drill site coal wall of an underground coal mine along with the coal bed, the hydraulic mechanical drill with the diameter changed and enlarged while drilling performs cave building on the borehole from inside to outside successively after the borehole reaches the preset depth, and the cave diameters and distances can be calculated through formulas. Coal bed stresses around the cave are released and coal bed prior cracks are widened and lengthened after the caves are completed, tensional and shear failures occur to the coal bed, novel cracks are produced, and accordingly, the coal bed crack connectivity is increased, the permeability is improved, the coal bed methane can be depressurized and desorbed rapidly, the coal bed methane extracting efficiency is improved dramatically, and the coal bed methane extracting time is shortened.

Owner:ZHONGBEI UNIV +1

A marking method for installation of ship anchor bolts

ActiveCN110053707BReduce drilling workloadThe distance position deviation is not too largeVessel designingOther workshop equipmentShip masterMesh grid

The invention discloses a line marking method for installing anchor bolts of a ship. A first reference line is pre-drawn on the deck along the ship's length direction or ship width direction, and then at a distance of n reference objects from the first reference line. Draw the second reference line, measure the distance between the first reference line and the second reference line, and compare it with the design requirements. If the conditions are met, the second reference line is determined. If the conditions are not met, the position of the second reference line is checked. Adjustment. Finally, draw the third reference line up to the xth reference line according to the above method, so as to draw reference lines in the length direction and width of the ship, and divide them equally according to the distance between two adjacent reference lines Draw a small grid to determine the location of the anchor bolt installation holes. The position error of the structural parts on the deck during the assembly process of the ship can be dispersed to the inside of each large grid, and by dividing the large grid into small grids, the errors are distributed by the small grids on the deck. Grid division digestion.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

Process for pumping and exploiting coal bed gas by using ground well drilling and underground hole drilling

The invention relates to a coal bed gas exploiting technique, in particular to a process for pumping and exploiting coal bed gas by together using ground well drilling and underground hole drilling, solving the problem of low efficiency of the traditional method for pumping and exploiting the coal bed gas. The process comprises the following steps of: (1) carrying out well drilling on the ground;(2) carrying out long hole drilling in underground coal beds; (3) making drilled holes and ground drilled wells crosslink and communicate in the appointed points by utilizing an orientation techniqueof a long hole drilling machine; (4) effectively closing the underground long drilled holes; (5) fracturing the ground drilled wells and the underground long drilled holes by utilizing fracturing equipment on the ground; (6) after fracturing, closing the ground drilled wells; and (7) opening the closed ends of the underground long drilled holes and then installing relevant pumping and dischargingpipelines connected with underground pumping and discharging systems. The process improves the pumping and exploiting speed and efficiency of the coal bed gas, shortens the construction period of coal bed gas pumping and exploiting engineering and saves the construction investment of the coal bed gas pumping and exploiting engineering.

Owner:山西蓝焰煤层气集团有限责任公司

A Multipurpose Steering Device with Variable Curvature External Prestressed Tendons

ActiveCN109797984BAchieve steeringAvoid damageBuilding repairsBuilding material handlingSupporting systemPre stress

The invention discloses a curvature-variable multipurpose turning device for external prestressed reinforcing steel. The curvature-variable multipurpose turning device comprises a supporting system and a curvature-variable turning system and is characterized in that the supporting system comprises a supporting body and a support plate, and the support plate is fixed to the supporting body; the supporting body is provided with a plurality of displacement adjusting grooves; the curvature-variable turning system comprises a turning component, a first fastening device and a second fastening device, the turning component comprises a plurality of turning units, and the bottom of each turning unit is provided with a groove for placing prestressed reinforcing steel; the first fastening device andthe second fastening device are connected with the turning component, and different turning radiuses can be achieved by adjusting the positions of different turning units on the displacement adjustinggrooves. The curvature-variable multipurpose turning device is safe, reliable, adjustable in turning radius, applicable to the external prestressed reinforcing steel of various diameters, convenientto transport, convenient to mount and the like.

Owner:SOUTHEAST UNIV

A device for expanding the scope of grouting reinforcement

ActiveCN111549782BExpand the radius of the grouting areaReduce drilling densityUnderground chambersFoundation engineeringStructural engineeringSlurry

Owner:CHINA RAILWAY SOUTH INVESTMENT GRP CO LTD +1

A kind of grouting reinforcement equipment for karst soft filling

ActiveCN111549756BIncrease workloadImprove work efficiencySoil preservationPiston ringStructural engineering

The invention provides a grouting reinforcement device for weak karst fillings. It includes a grouting pipe, a grouting barrel and a grouting valve; along the height direction of the grouting barrel, a plurality of partitions are arranged inside the grouting barrel, and two adjacent partitions and the side wall of the grouting barrel form a grout containing chamber , a plurality of telescopic grouting valves are slidably connected to the side wall of the grouting barrel, and each grouting valve is located between two partitions; one end of the grouting pipe provided with a grouting hole passes through the grouting barrel The clapboard is slidably connected with the grouting barrel along the height direction, and piston rings are arranged on both sides of the grouting hole along the height direction of the grouting pipe. In the present invention, multiple layers of grout containing chambers are arranged inside the grouting bucket, and a grouting valve is arranged on the side wall of each grouting chamber, so that the grouting pipe can be applied to the strata of different depths for grouting reinforcement, which can reduce the need for workers to lift Reduce the workload of the overall grouting equipment and improve the efficiency of grouting work.

Owner:CENT SOUTH UNIV +1

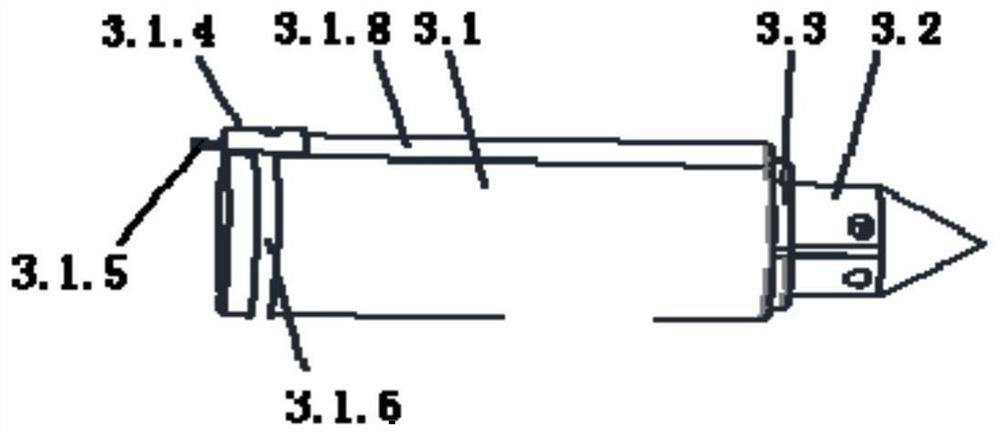

Compound energy-concentrating blasting cartridge and production method thereof

InactiveCN101709933BTo achieve the purpose of directional fractureReduce supporting costsBlasting cartridgesEngineeringHigh pressure water

The invention discloses a compound energy-concentrating blasting cartridge and a production method thereof. The blasting agent is arranged in a double-layer tube, the double-layer tube is respectively provided with an inner tube kerf and an outer tube kerf, and couplant water is added in the clearance between the two tubes. Thus, the blasting cartridge firstly produces high pressure gas jets at the moment of blasting, water jets are formed through the energy concentration at the kerf of the inner tube, and the energy of the water jets are strengthened through the energy concentration at the kerf of the outer tube to form high pressure water jets, thereby impacting the wall of the blast hole and achieving the goal of oriented cracking. Thus, from the perspective of energy concentration, the compound energy-concentrating blasting cartridge can form the effect of energy concentration twice, which is twice as the energy concentrated by a normal cut blasting cartridge; and from the perspective of enclosing rock protection, the compound energy-concentrating blasting cartridge adopts a double-layer tube which is twice as the common cut blasting cartridge, and the enclosing rock protection effect is better than that of the common cut blasting cartridge, thereby further reducing the supporting cost.

Owner:HOHAI UNIV

A method for expanding the scope of grouting reinforcement for filling and semi-filling karst

InactiveCN111549758BExpand the radius of the grouting areaReduce drilling densitySoil preservationSoil scienceSlide plate

The invention provides a method for expanding the scope of grouting reinforcement for filling and semi-filling karst. Lower the assembled grouting equipment into the bottom of the grouting hole, and the grouting pipe and the upper part of the grouting bucket are above the ground; for grouting, inject grout into the grouting cavity of the grouting bucket through the rigid grouting pipe, The grout makes the grouting valve protrude under pressure and penetrate into the formation. The first end of the outer sleeve is close to the inner wall of the grouting bucket. The through hole of the sealing slide plate, the first slurry flow hole of the outer sleeve, the second slurry flow hole of the outer sleeve, the first slurry flow hole of the interlayer sleeve, the second slurry flow hole of the interlayer sleeve, the inner drill core slurry flow hole and the grouting diffusion hole Connected, the grout flows into the formation to be reinforced by grouting. The invention greatly reduces the drilling workload of construction personnel, and at the same time expands the scope of grouting reinforcement. The expansion and contraction of the grouting valve can be realized only by adjusting the grouting pressure, and the operation is simple and convenient.

Owner:张永刚 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com