Explosion-proof and pollution-proof drilling machine

A drilling machine and anti-pollution technology, applied in the direction of boring/drilling, drilling/drilling equipment, boring machine/drilling machine parts, etc., can solve the problems of long time consumption, failure to proceed as usual, loss of transformer oil, etc., to achieve The effects of avoiding air pollution, less workload, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

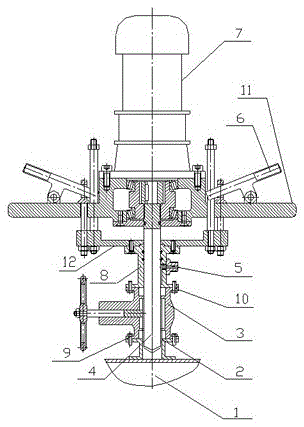

[0011] Such as figure 1 shown. The present invention mainly includes a connecting flange 2, a gate valve 3, a twist drill 4, two inlet and exhaust ports 5, a fixed bracket 11, a movable bracket 12, two control handles 6, an explosion-proof motor 7, and a docking flange 8. The fixed bracket 11 is fixed on the fuselage of the explosion-proof motor 7, the movable bracket 12 is threadedly connected with the fixed bracket 11 through two screws, and the two joysticks 6 are symmetrically mounted on the fixed bracket 11 to adjust the lifting of the screw rod; the docking flange 8 , gate valve 3 and connecting flange 2 are connected in sequence, and are set on the twist drill 4; the butt flange 8 is fixedly connected with the movable bracket 12, and two inlet and outlet ports 5 are arranged on it. Screw rod on the fixed support 11 and joystick 6 are two, and symmetrical installation. Work preparation: Weld the connecting flange 2 to the main transformer, install the gate valve 3 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com