A Spline Type Horizontal Directional Drilling Engineering Geological Exploration Control Device

A technology of horizontal orientation and engineering geology, applied in directional drilling, undisturbed core extraction devices, drilling equipment, etc., can solve problems such as complex situations, difficult implementation, and inability to obtain cores, so as to reduce engineering costs, increase service life, and reduce work volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with drawings and embodiments.

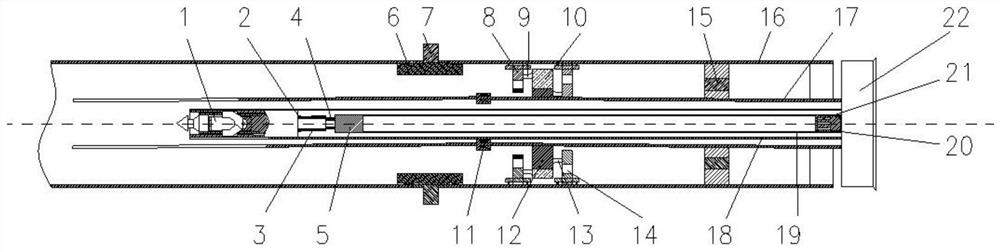

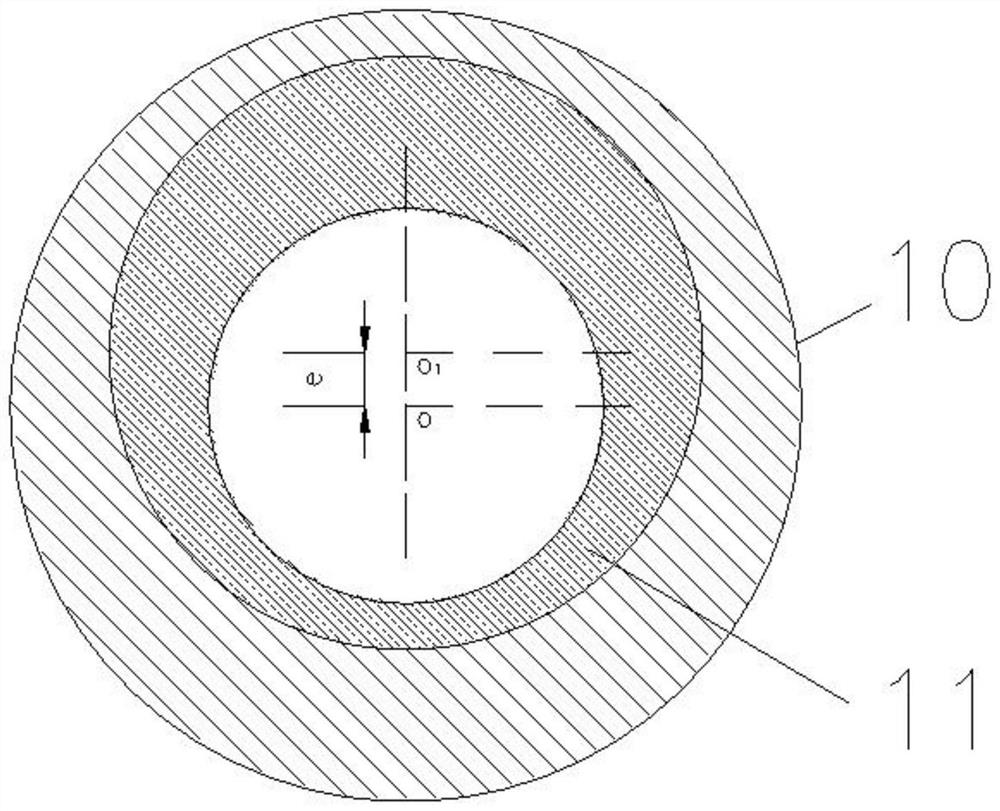

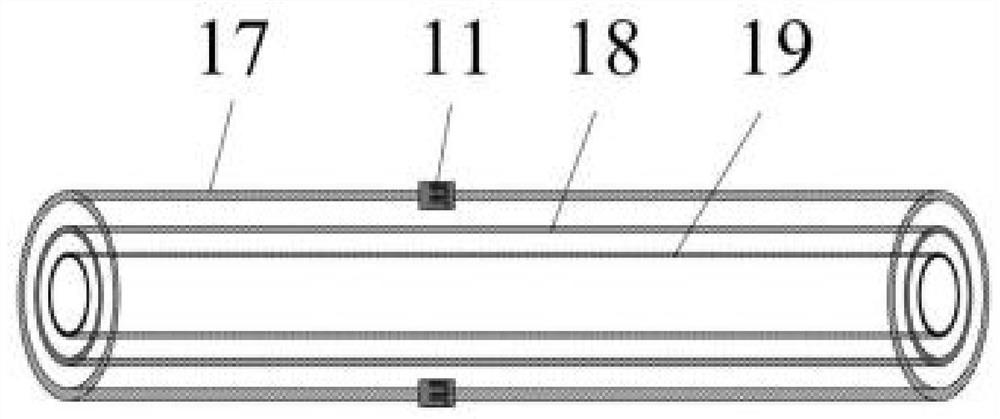

[0024] Such as figure 1 As shown, the spline-type horizontal directional drilling engineering geological survey control device includes a casing 16, a core outer pipe 17, a core inner pipe 19 and coring and fishing components. The rock core outer pipe 17 and the rock core inner pipe 19 are installed inside the casing 16 , an eccentric guiding part is arranged between the outer core tube 17 and the casing 16, and the eccentric guiding part includes an inner eccentric ring 12, an outer eccentric ring 10 and a spline 11, and the inner diameter of the inner eccentric ring 12 is closely fitted to the outer wall of the outer core tube 17 , the outer wall of the inner eccentric ring 12 is closely attached to the outer eccentric ring 10, the outer eccentric ring 10 is connected to the outer eccentric ring control motor 9 arranged on the inner wall of the casing 16 through the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com