Process for pumping and exploiting coal bed gas by using ground well drilling and underground hole drilling

A surface drilling and coalbed methane technology, which is applied in earthwork drilling, wellbore/well components, and mining fluids, etc., can solve the problems of low efficiency of coalbed methane extraction methods, improve the influence range of extraction, shorten the construction period, Effect of flow resistance reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

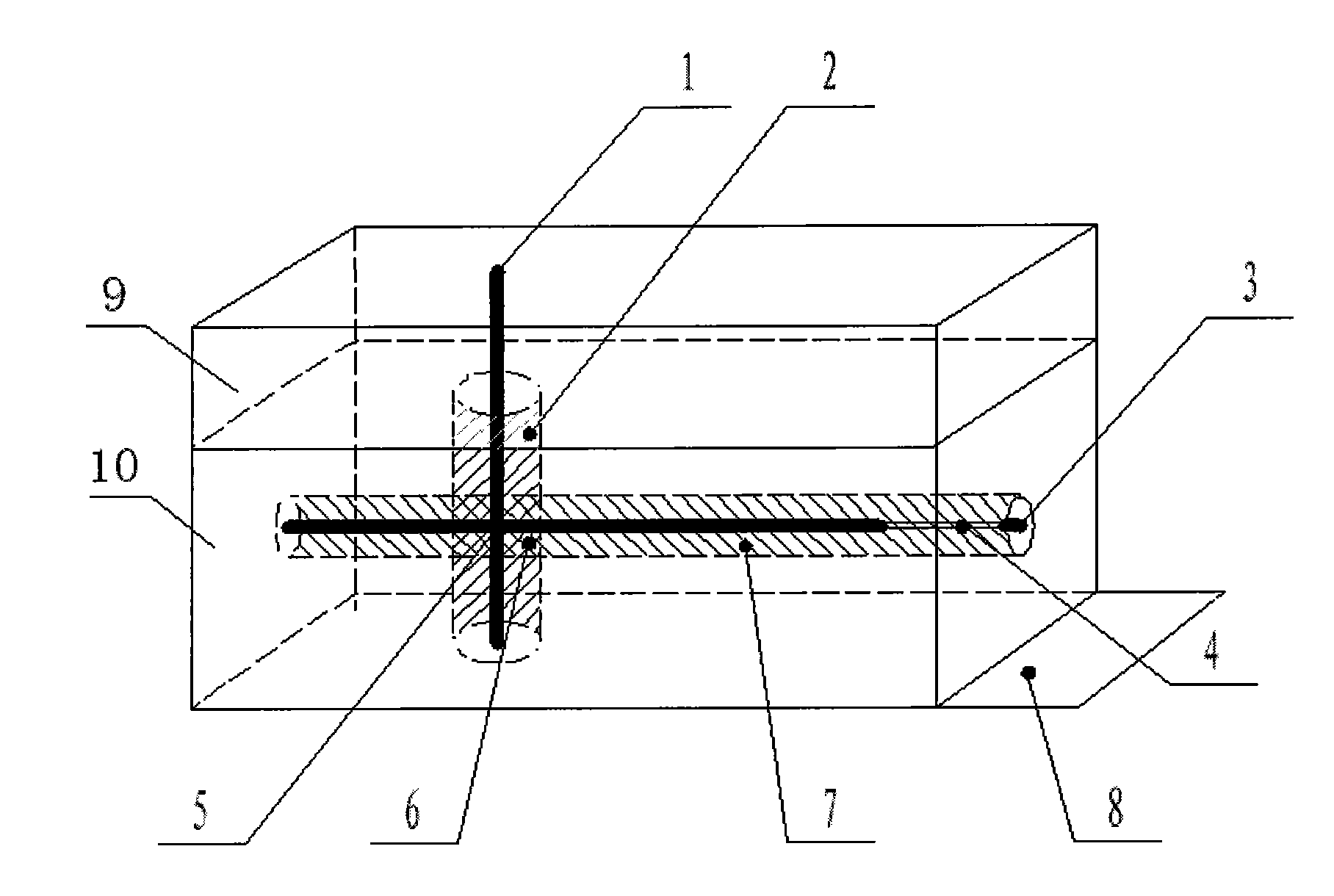

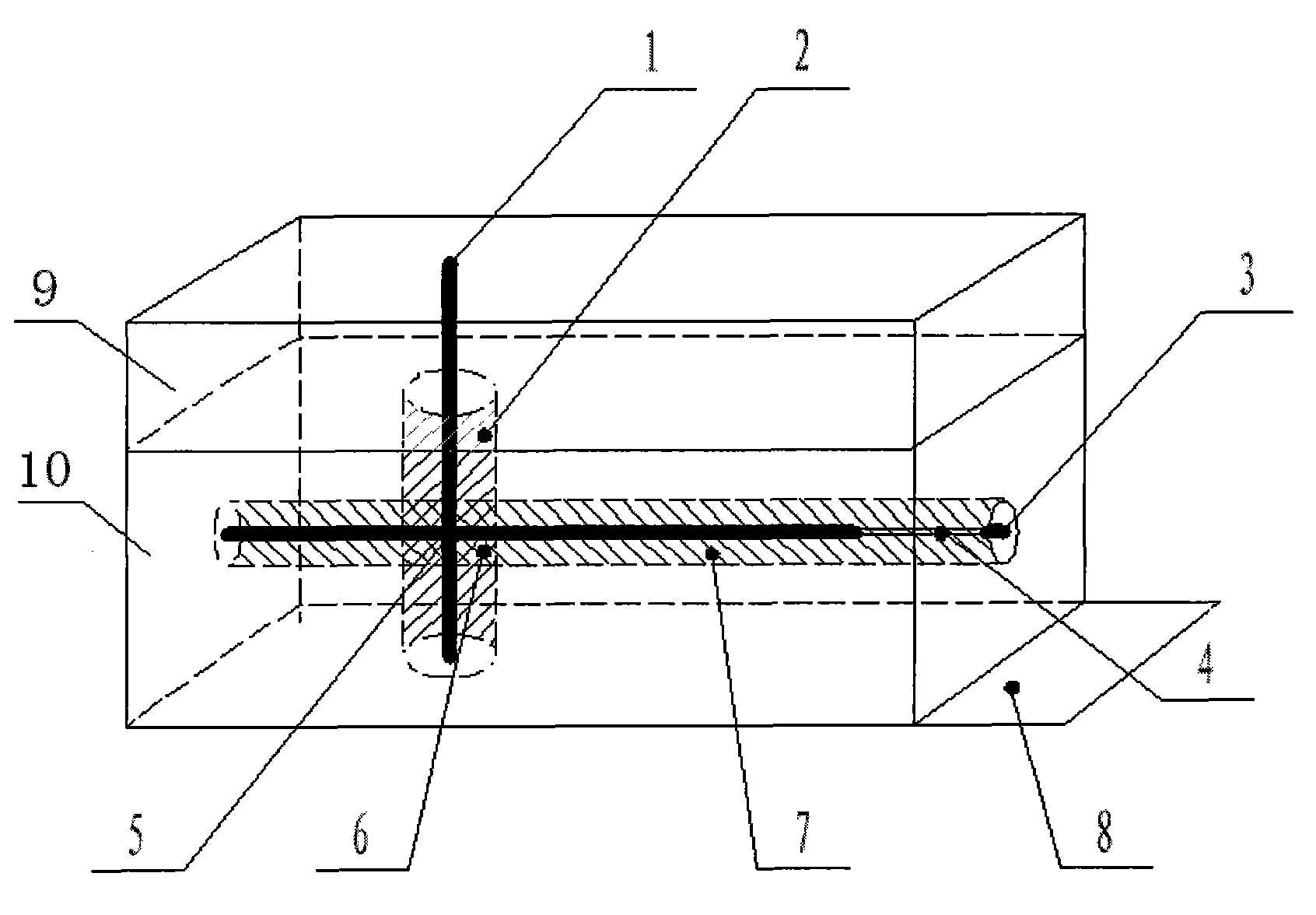

[0012] Such as figure 1 Illustrated, a kind of ground drilling and downhole drilling combined extraction technique for coalbed methane comprises the following steps, (1) constructing ground drilling 1 on the ground, with a construction point every 250 meters in the straight line direction; Construction of long borehole 3 in 10, constructing a borehole with a horizontal direction of 30-50 meters, (3) utilizing the directional technology of the long borehole drilling machine to make the long borehole 3 and the ground well 1 cross-linked at the designated intersection point 5, (4) Effectively seal the long borehole 3 in the well, and the length of the closed area 4 is 20 meters to 30 meters. (5) Use fracturing equipment on the ground to perform fracturing on the ground well 1 and the long borehole 3 in the well to generate the affected area of the ground well fracturing 2 and the long borehole fracturing affected area 7, the fracturing pressure is 6-10MPA, (6) after the fractur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com