Liquid sampling apparatus

A liquid sampling and liquid technology, applied in the direction of sampling devices, etc., can solve the problems of large bubble content in the syringe, waste of sample solution, and long time-consuming dilution, and achieve the effect of saving liquid drainage time, saving extraction time, and shortening sampling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

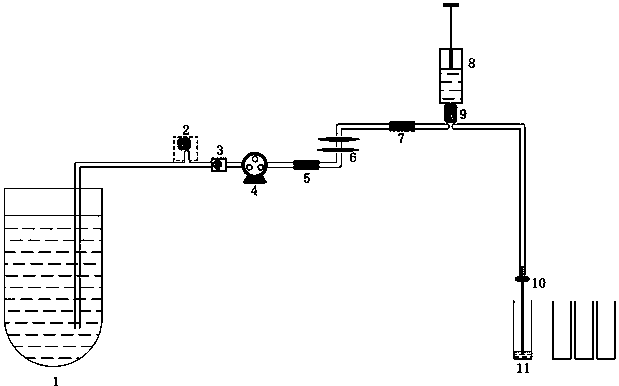

[0042] Such as figure 1 As shown, a liquid sampling device includes a sampling pipeline, a liquid discharge pipeline and a plunger pump 8, and the plunger pump 8 is connected to the sampling pipeline and the liquid discharge pipeline, and is extracted from the sample cup 1 through the sampling pipeline. Liquid, the liquid is discharged into the sampling bottle through the liquid discharge pipeline; the setting structure of the plunger pump 8 can adopt the structure commonly used in the prior art, such as the plunger pump of a quantitative sampling device disclosed in CN101639420A mentioned in the background technology 8, the setting method does not belong to the improvement of the present invention, so it will not be described too much. In the present invention, a peristaltic pump 4 is added on the sampling pipeline. After the peristaltic pump 4 is turned on, it can pump liquid into the plunger pump 8; in order to coordinate the speed of the plunger pump 8 and the peristaltic ...

Embodiment 2

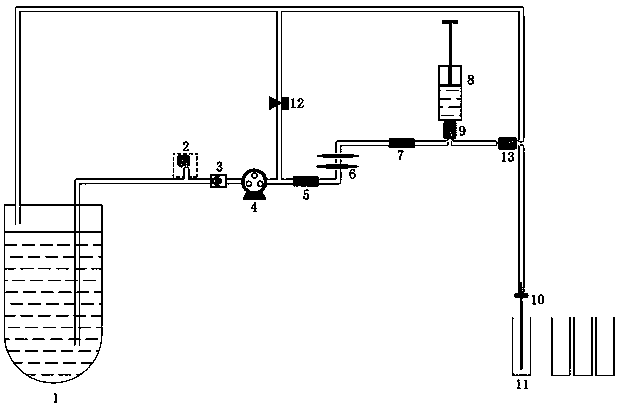

[0050] On the basis of the first embodiment, the sampling device further includes a liquid return pipeline and an intermediate pipeline. One end of the liquid return pipeline is connected to the plunger pump 8 through a valve, and is usually connected to the discharge pipeline through the three-way solenoid valve 213, and whether the plunger pump is connected to the discharge pipeline or not is realized by switching the three-way solenoid valve 213. Connected to the return line. The other end of the liquid return line is placed above the sample cup 1 . One end of the intermediate pipeline is connected to the liquid return pipeline, and the other end is connected between the peristaltic pump 4 and the filter 6 of the sampling pipeline. The intermediate pipeline is provided with a pressure tube valve 12 controlled by a controller. The pipeline is used for peristaltic pump 4 and previous pipeline flushing and filter 6 backwashing.

[0051] In the normal state, the pressure tube...

Embodiment 3

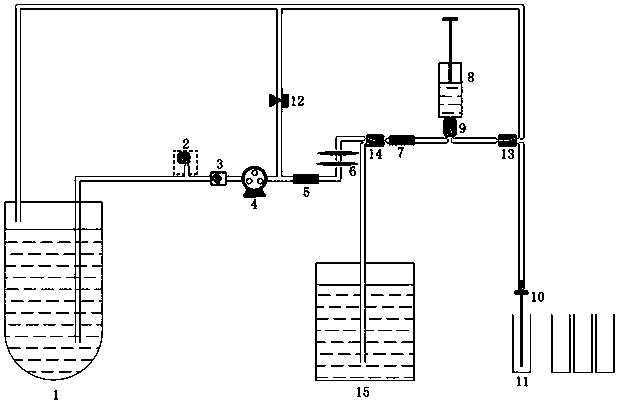

[0053] During the sampling process of the drug dissolution experiment, because the sampling consumes part of the solution, it is sometimes necessary to add a pure solution to the sample cup 1 for the drug dissolution. For this reason, on the basis of the second embodiment, the liquid sampling device of this embodiment also includes a liquid replacement tube. One end of the liquid replenishment tube is placed in the liquid replenishment cup 15 containing the pure solution to be replenished, and the other end is connected to the plunger pump 8 through a valve, usually connected to the sampling pipeline through a three-way solenoid valve 3 14, and the connection point is between the filter 6 and the first The pressure sensors 7 are as close as possible to the first pressure sensor 7, which can shorten the pipeline for pumping and supplementing the solution, and can also reduce the pipe resistance and shorten the time-consuming for pumping the solution. By monitoring the first pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com