Phase separator

A technology of phase separators and branch pipelines, applied in separation methods, chemical instruments and methods, sampling devices, etc., can solve problems such as complex internal structures, affecting the accuracy of sampling and measurement, and difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The phase separator of the present invention will be further described below in conjunction with the accompanying drawings.

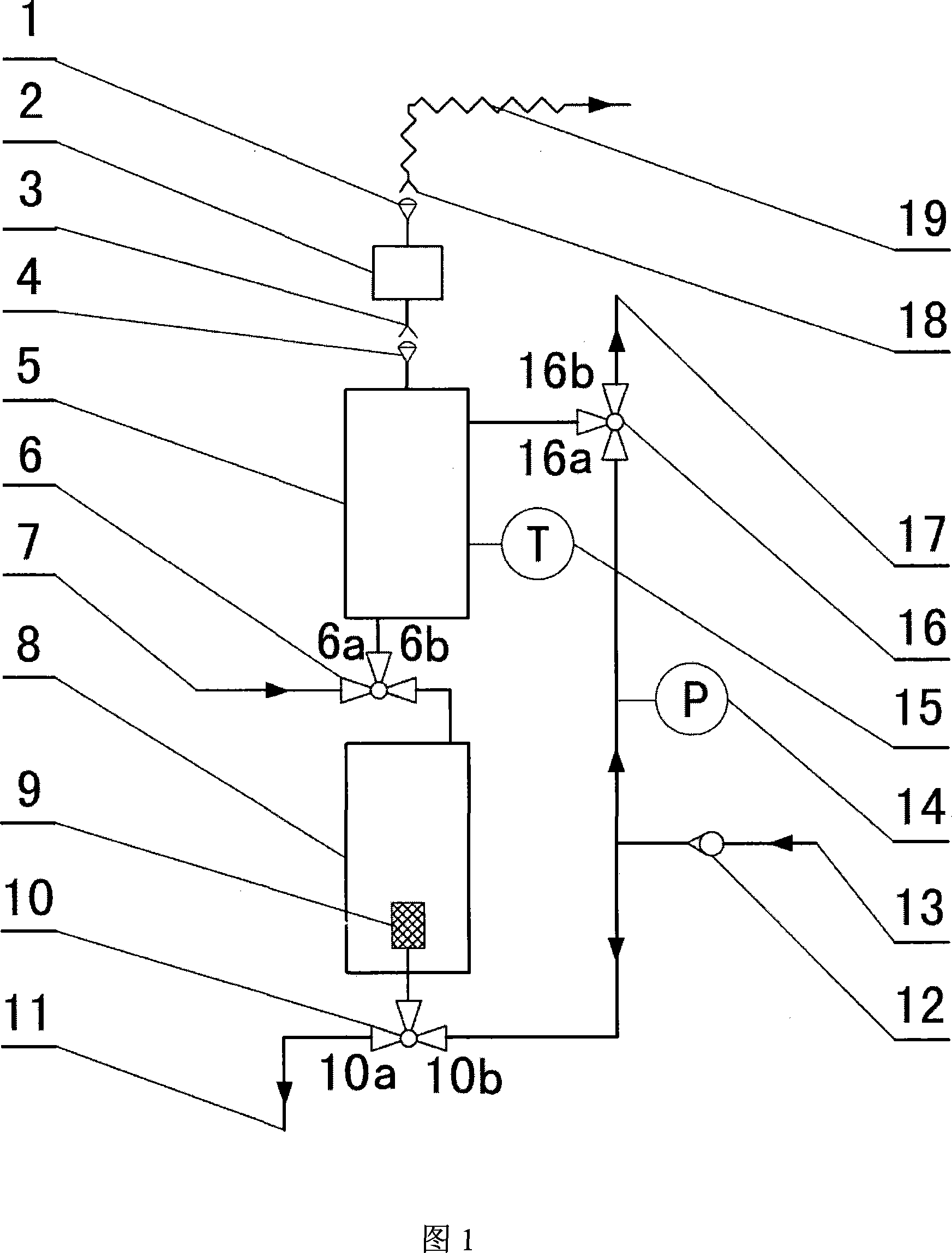

[0019] The phase separator of the present invention comprises a sampling unit, a vacuum line for evacuating the sampling unit and a bubbling line for feeding nitrogen (or inert gas) into the sampling unit.

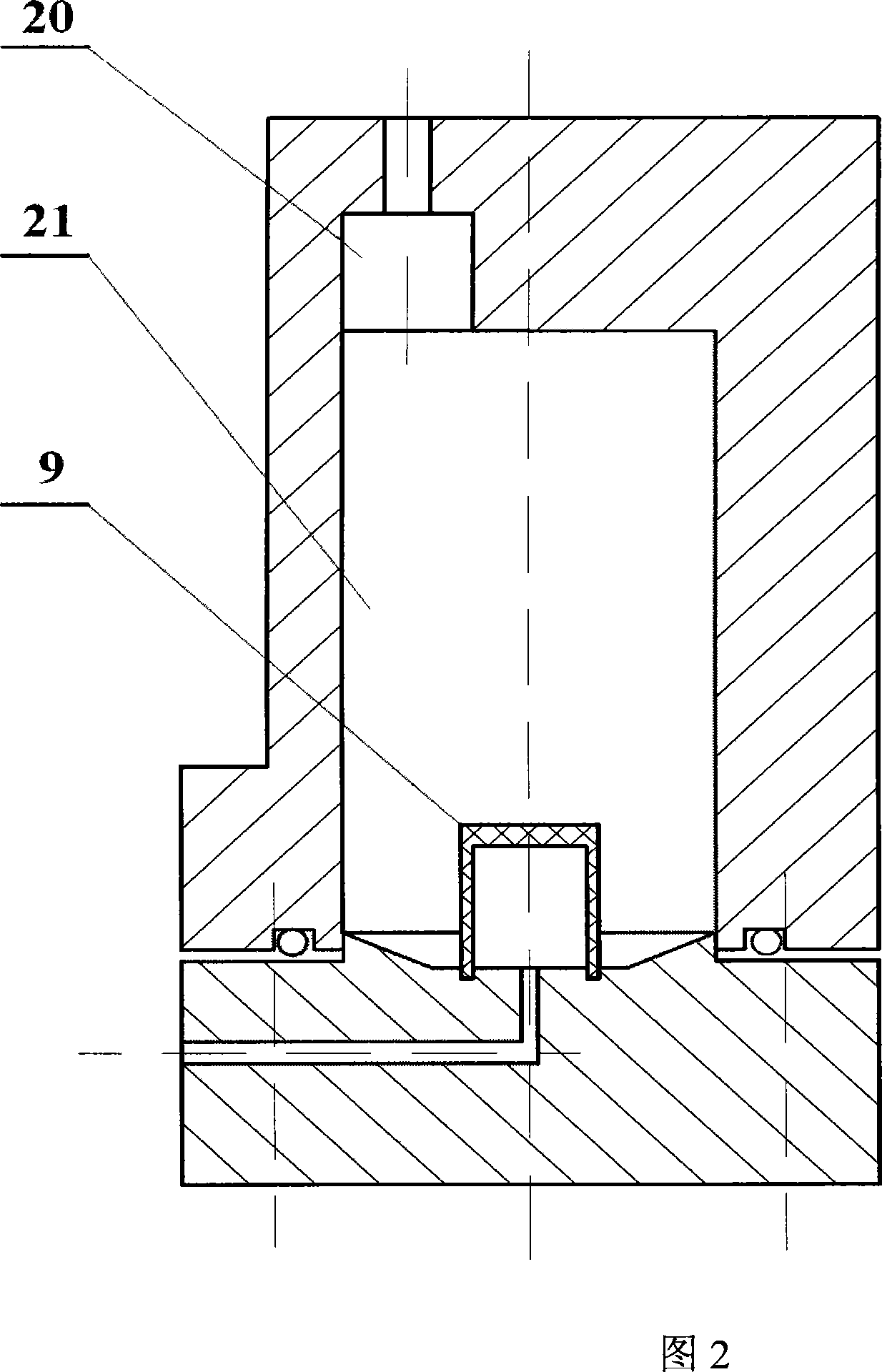

[0020] As shown in Figure 1, sampling unit comprises sampling-separator 5, the separator 8 that is provided with below sampling-separator 5, the gas sampling bottle 2 that is provided with above sampling-separator 5, in sampling-separator 5 A thermometer 15 that can directly read data is provided on the top. As shown in Figure 2, the inside of the separator 8 is divided into upper and lower cavities, the upper cavity 20 is an eccentric structure, and the center of the lower cavity 21 is provided with a bubbling element 9, and the volume of the lower cavity is the same as that of the sampling-separator 5. The same volume (or no more than 110%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com