Wave making method for generating continuous focused waves in wave water tank within short time

A short-time, wave technology, applied in hydraulic models and other directions, can solve the problems of long-term, continuous focused wave simulation without public reports, exceeding the test sampling capacity, etc., to improve efficiency, shorten the sampling time, and meet the wave trough test. effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

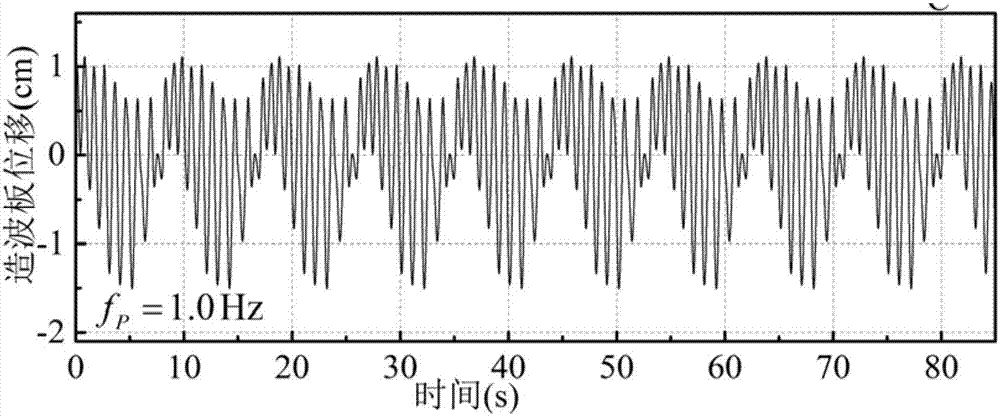

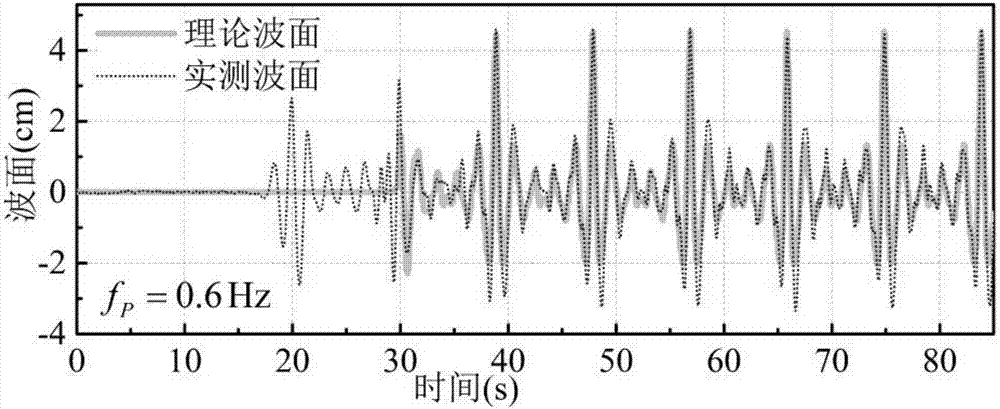

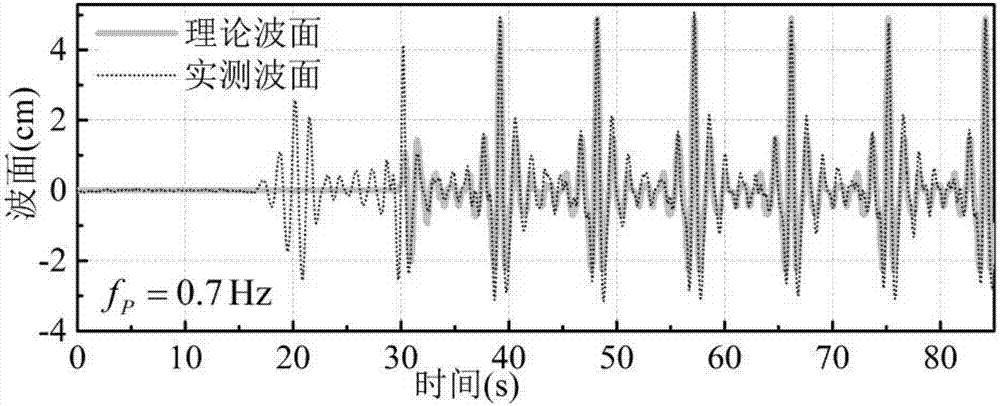

[0067] Such as Figure 1-8 As shown, the effectiveness and accuracy of the continuous focused wave wave-making method proposed by the present invention are verified through specific wave tank tests.

[0068] A wave-making method that generates continuous focused waves in a wave tank in a short period of time, using a push plate type wave-making machine to make waves. The specific method is as follows: Based on the principle of linear superposition, the two-dimensional wave surface can be expressed as:

[0069]

[0070] in:

[0071] N f - total number of component harmonics;

[0072] a i —Amplitude of constituent waves (m);

[0073] k i ——the number of constituent waves;

[0074] ω i ——Composition angular frequency (rad / s);

[0075] φ i —Initial phase of the constituent waves (rad).

[0076] Wavenumber and frequency satisfy the dispersion relation:

[0077] ω i 2 =gk i tanh(k i d) (2)

[0078] in:

[0079] g—gravitational acceleration (the value is 9.8m / s 2...

Embodiment 2

[0113] A wave-making method that produces continuous focused waves in a wave tank in a short period of time. It uses a rocker-type wave-making machine to generate waves. The specific method and theoretical derivation process are similar to those of the push-plate type, except that it is different in calculating the displacement signal of the rocker plate. The following will be explained in turn.

[0114] The wave surface function at the focal point of the continuous focused wave in the tank has nothing to do with the type of the wave maker. The wave surface of the continuous focused wave generated by the wave maker equipped with a rocking plate at the focal point is still Equation (13), and at the position of the wave maker The wave surface of is formula (14). Hydraulic transfer function T(f i )for:

[0115]

[0116] The wave surface time history curve of each frequency component included in it can be brought back to formula (11) to obtain the motion signal of the wave-ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com